Angle Measurement Method Based on Wireless Power Transmission and Electromagnetic Induction

A technology of wireless power transmission and angle measurement, applied in the direction of measuring device, using electromagnetic means, using electric device, etc., can solve the problems of sensor not working normally, sensor damage, poor vibration resistance, etc., to solve the problems of reliability, low cost, Ease of maintenance and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

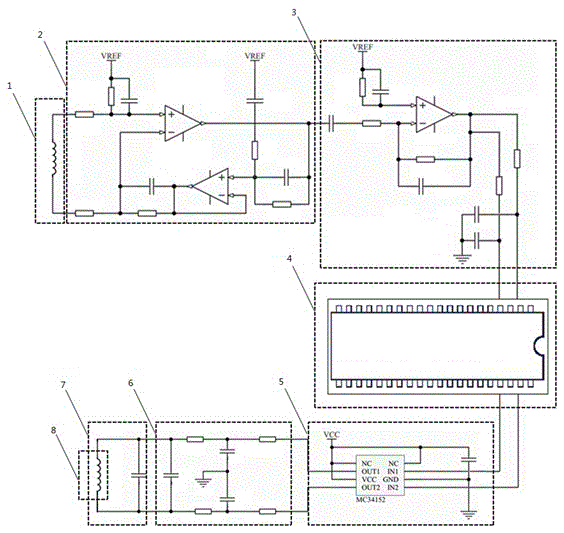

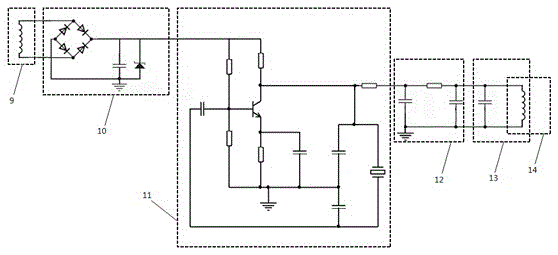

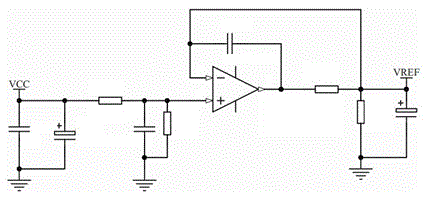

[0047] The present invention will be further described below in conjunction with accompanying drawing

[0048] Such as Figure 1 to Figure 6 As shown, the stator circuit of the present invention includes:

[0049] The single-chip microcomputer 4 is used to generate and process electrical signals, and according to the received electrical signals, process the electrical signals to obtain angle values, and output them to the display screen; the single-chip microcomputer can use the model TMS320C28027.

[0050] A high-frequency square wave signal amplification circuit 5 is used to amplify the power of the energy supply high-frequency square wave signal output by the single-chip microcomputer;

[0051] The high-frequency square wave signal filter circuit 6 filters the output or input electrical signal to reduce the interference of external clutter;

[0052] The energy supply AC signal resonant circuit 7 performs current amplification on the output energy supply AC signal;

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com