Chain coal cutter

A coal cutting machine and chain technology, applied in cutting machinery, earthwork drilling and other directions, can solve the problem of inability to realize coal cutting and mining, and achieve the effects of high coal mining efficiency, large coal mining area and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

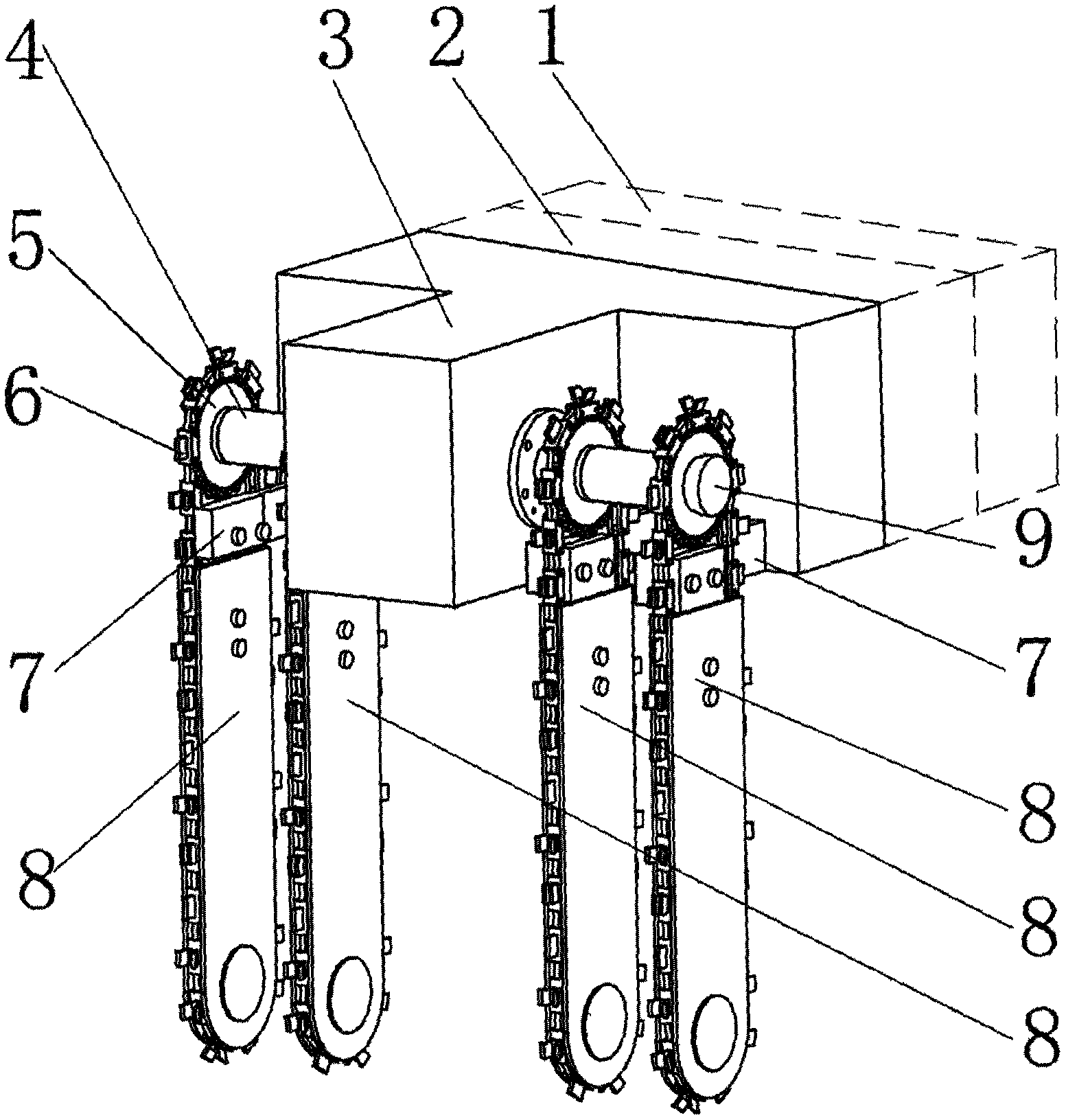

[0033] Such as figure 1 , figure 2 The shown embodiment 1 discloses a chain coal cutter, including a traction part 1, a motor part 2, and a coal cutting part; the traction part 1 is connected to the box body 11, and the motor part 2 and the transmission part 3 are located In the box body 11, the motor part 2 is connected and drives the coal cutting part through the transmission part 3; the box body 11 has a T-shaped structure, and the coal cutting part is arranged outside the box body 11, on both sides of the T-shaped protruding part, and is distributed in a symmetrical structure .

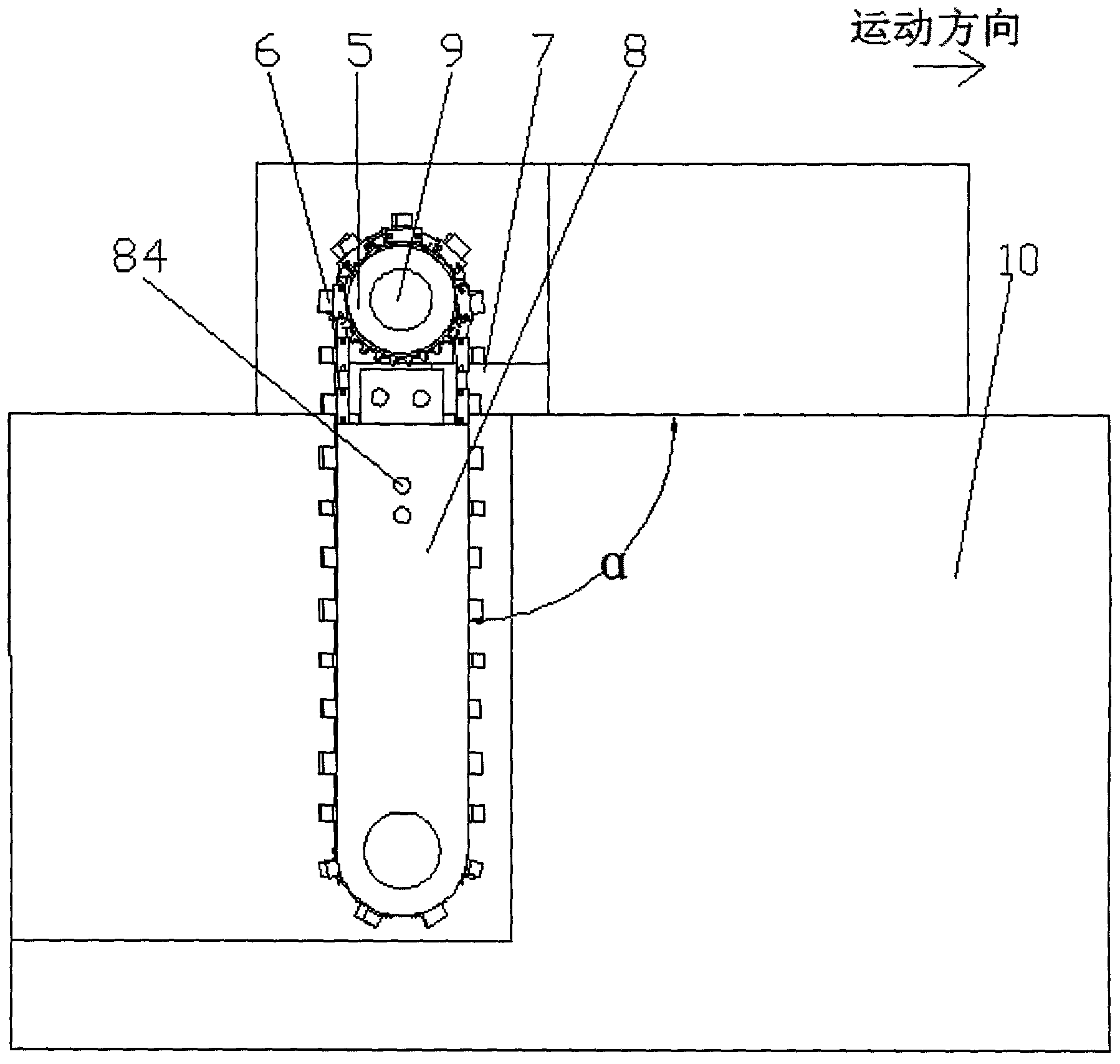

[0034] The coal cutting part is used for cutting the coal seam 10 below the box body 11 . In this embodiment, the transmission part 3 has a sprocket shaft 4, and the two ends of the sprocket shaft 4 pass through the two ends of the T-shaped protrusion of the box body 11. The transmission part 3 drives the sprocket shaft 4 to rotate through the motor part 2, and the transmission part 3 Output a...

Embodiment 2

[0042] This embodiment discloses a chain coal cutter, which includes a traction part 1, a motor part 2, and a coal cutting part. The difference between this embodiment and embodiment 1 is:

[0043]Two sprockets 5 are arranged symmetrically on the sprocket shaft 4 , that is, there is one sprocket 5 on each side of the T-shaped protrusion of the box body 11 . The position of the sprocket 5 is fixed by setting the sleeve 41 between the sprocket 5 and the T-shaped protrusion of the box body 11; the outermost end of the sprocket shaft 4 has an end cover 9, and the sprocket 5 and the sleeve 41 are installed and covered. The end cap 9 fixes the positions of the two sprockets 5 . It is also possible to change the distance between the pre-prepared sprockets according to actual needs by replacing the sleeve 41 or adjusting the length of the sleeve, so that the cutting effect of the coal cutter meets the predetermined coal mining effect of a specific coal seam.

[0044] The chain plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com