Drill rod capable of reducing friction and pressure and removing rock debris

A cuttings bed and drill pipe technology, applied to drill pipes, drill pipes, drilling equipment, etc., can solve downhole complex problems, affect the life of oil and gas wells, and drill sticking, so as to reduce the probability of occurrence, reduce well complex problems, and enhance Effect of Rock Carrying Ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

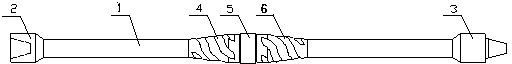

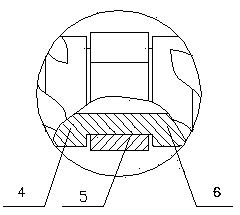

[0015] Such as figure 1 , 2 As shown, the invention discloses a drill pipe for reducing friction and reducing pressure to remove cuttings bed. As shown in the figure: it includes a drill pipe body 1 and a female threaded joint 2 and a male threaded joint 3 arranged at both ends of the drill pipe body 1. The surface of the drill pipe body 1 is sequentially provided with a first helical groove 4, a bearing type The protective cover 5 and the second spiral channel 6 .

[0016] As a preferred structure, the groove top diameters of the spiral channels 4, 6 are not larger than the outer diameters of the female threaded joint 2 and the male threaded joint 3, and the groove bottom diameters of the spiral channels 4, 6 are larger than the outer diameter of the drill pipe body 1.

[0017] As a preferred structure, the outer diameter of the bearing-type protective sleeve 5 is larger than the groove top diameters of the spiral channels 4, 6; the bearing-type protective sleeve 5 is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com