Streamline PDC drill bit capable of improving rock carrying capability and design method of streamline PDC drill bit

A design method and streamlined technology, applied in drill bits, drilling equipment, design optimization/simulation, etc., can solve problems such as low rock-carrying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to have a clearer understanding of the design, purpose and effect of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

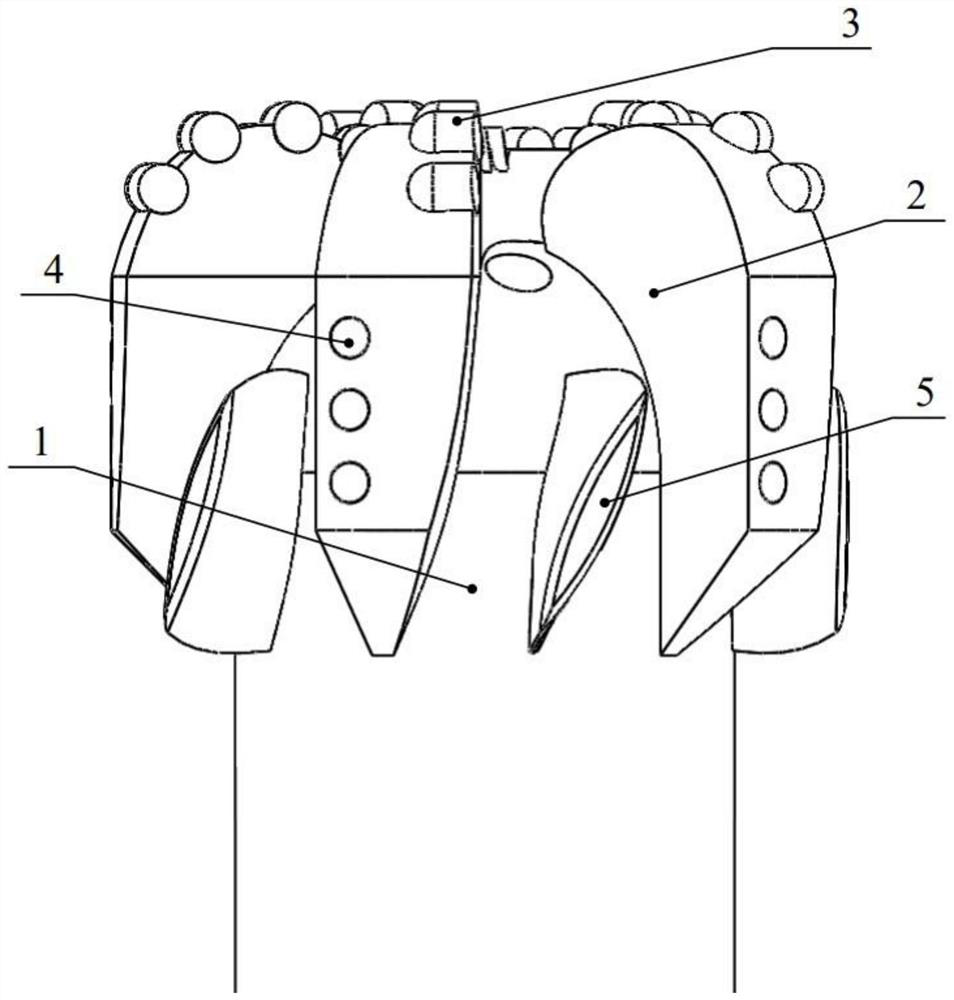

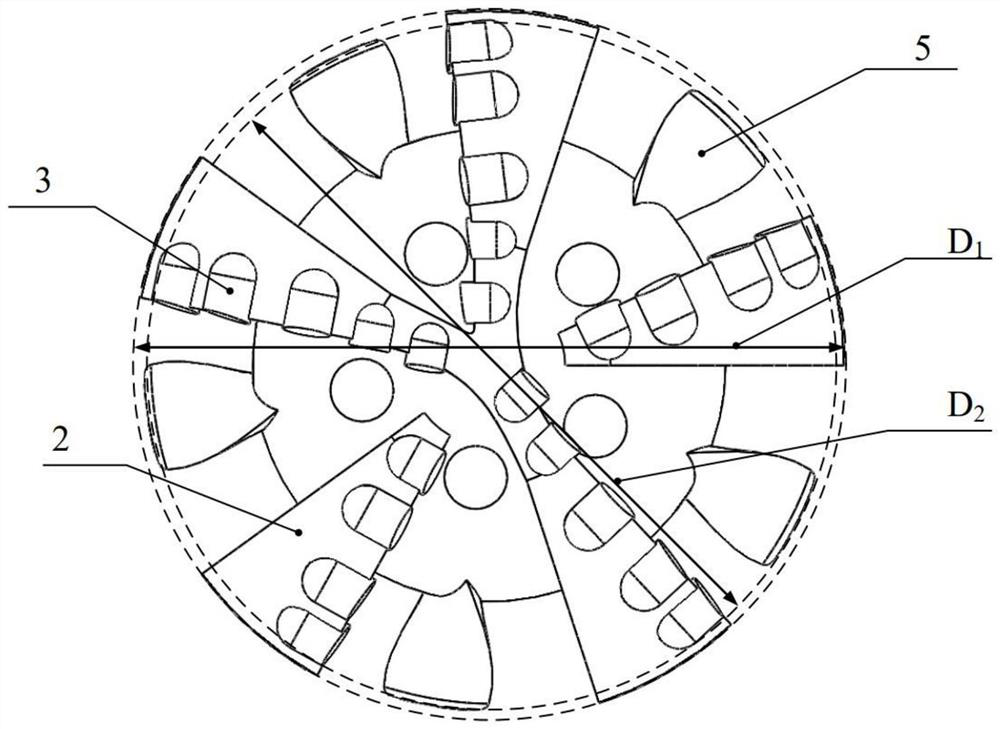

[0037] like figure 1 As shown, a structural schematic diagram of a streamlined PDC drill bit that improves rock-carrying capacity provided by the present invention includes: a drill body 1, a new streamlined blade 2, PDC teeth 3, gauge teeth 4, splitter blades 5, and a drill body 1 Five new streamlined blades 2 are arranged on the top, and a splitter blade 5 is arranged on the flow channel between the tails of each adjacent two blades, and the splitter blade 5 is fixedly connected with the drill body 1 .

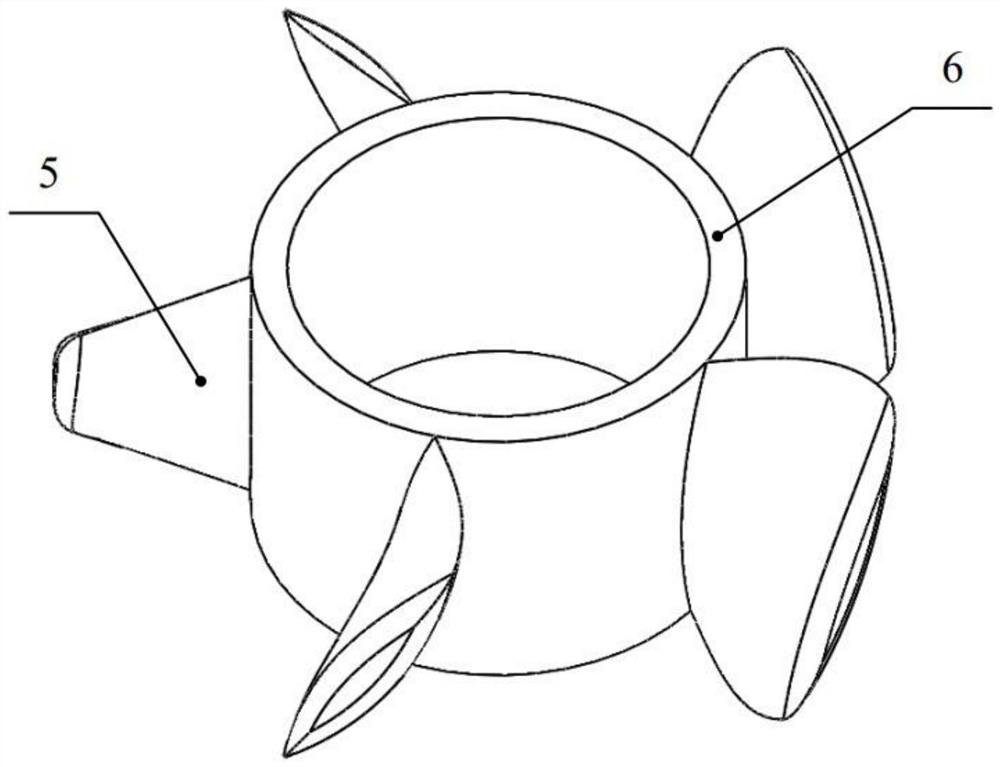

[0038] The splitter blade 5 is an asymmetrically twisted blade, and the airfoil from the root of the blade to the edge of the blade is composed of airfoils with different thicknesses and different chord lengths. It is fitted by five differe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com