Method for separating active component-glabridin contained in natural product glycyrrhiza glabra

A technology of ionic liquid and glabridin, which is applied in the direction of organic chemistry, can solve the problems of difficult regeneration and large consumption of ionic liquid, and achieve the effect of low cost, simple method and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Using ionic liquid [Hmim][NTf 2 ] as the extraction agent, and the hydrophobic polyvinylidene fluoride membrane (PVDF) with a pore size of 0.22 μm as the support membrane material, pressurized to 0.2 MPa to prepare the ionic liquid support liquid membrane.

[0028] (2) Prepare a glabridin raw material solution with a concentration of 0.02-0.45 mg / mL with ethanol aqueous solution.

[0029] (3) Prepare a NaOH solution with a concentration of 0.1 mol / L with distilled water.

[0030] (4) The glabridin raw material solution obtained in step (1) and the 0.1mol / L NaOH stripping liquid obtained in step (2) are added respectively in the raw material liquid pool A and the stripping liquid pool B, and the magnetic stirring speed is 260rpm , the extraction time is 20 hours.

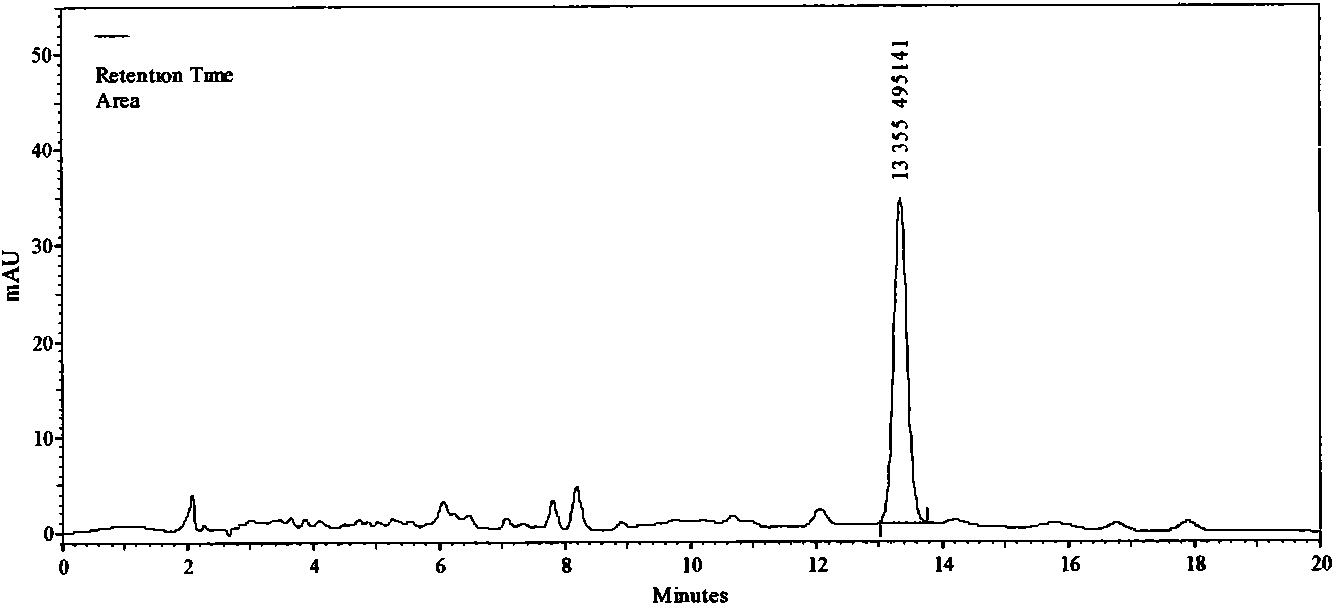

[0031] (5) The samples were determined by reverse-phase high-performance liquid chromatography (RP-HPLC). The extraction rate of glabridin was 70.13%-85.65%, and the total recovery rate of glabridin was ...

Embodiment 2

[0033] (1) Using ionic liquid [Hmim][NTf 2 ] As the extraction agent, the hydrophobic polyvinylidene fluoride membrane (PVDF) with a pore size of 0.22 μm was used as the support membrane material, and the pressure was increased to 0.2 MPa to prepare the ionic liquid support liquid membrane.

[0034] (2) Prepare a 0.25 mg / mL glabridin raw material solution with ethanol aqueous solution.

[0035] (3) Prepare a NaOH solution with a concentration of 0.02-0.5 mol / L with distilled water.

[0036] (4) step (1) obtains glabridin raw material liquid and the NaOH back extraction liquid that step (2) obtains and adds respectively in raw material liquid pool A, back extraction liquid pool B, and the rotating speed of magnetic stirrer is 260rpm, and extraction time is 20 hours.

[0037] (5) Determination of samples by reverse-phase high-performance liquid chromatography (RP-HPLC), the extraction rate of glabridin was 75.67%-86.34%, and the total yield of glabridin was 71.47%-85.84%. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com