Breeding manure biological drying system and method in farm

A bio-drying system and bio-drying workshop technology, applied in climate change adaptation, organic fertilizers, fertilization devices, etc., can solve the problems of large one-time investment, unacceptable market acceptance, and high production costs of chemical treatment technology, and achieve the solution of feces The effect of transporting secondary pollution, solving epidemic prevention problems, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be described in further detail below in conjunction with the accompanying drawings.

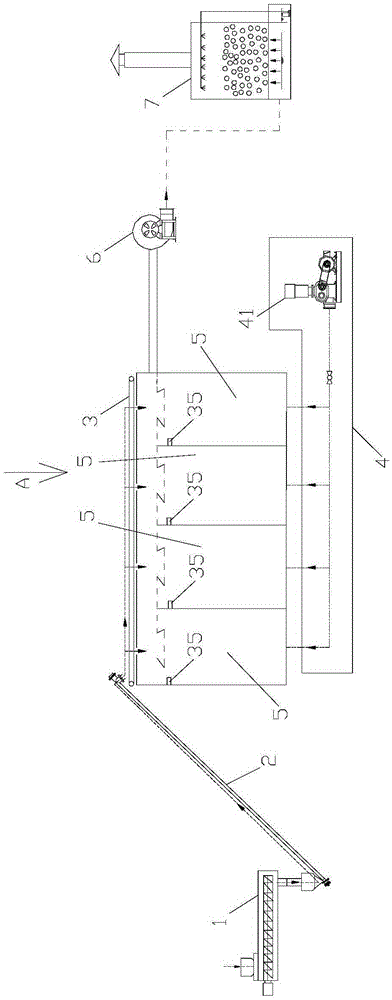

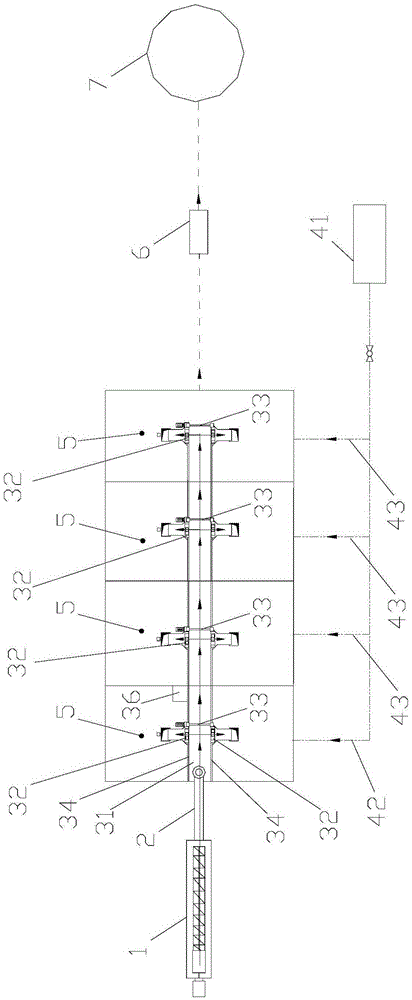

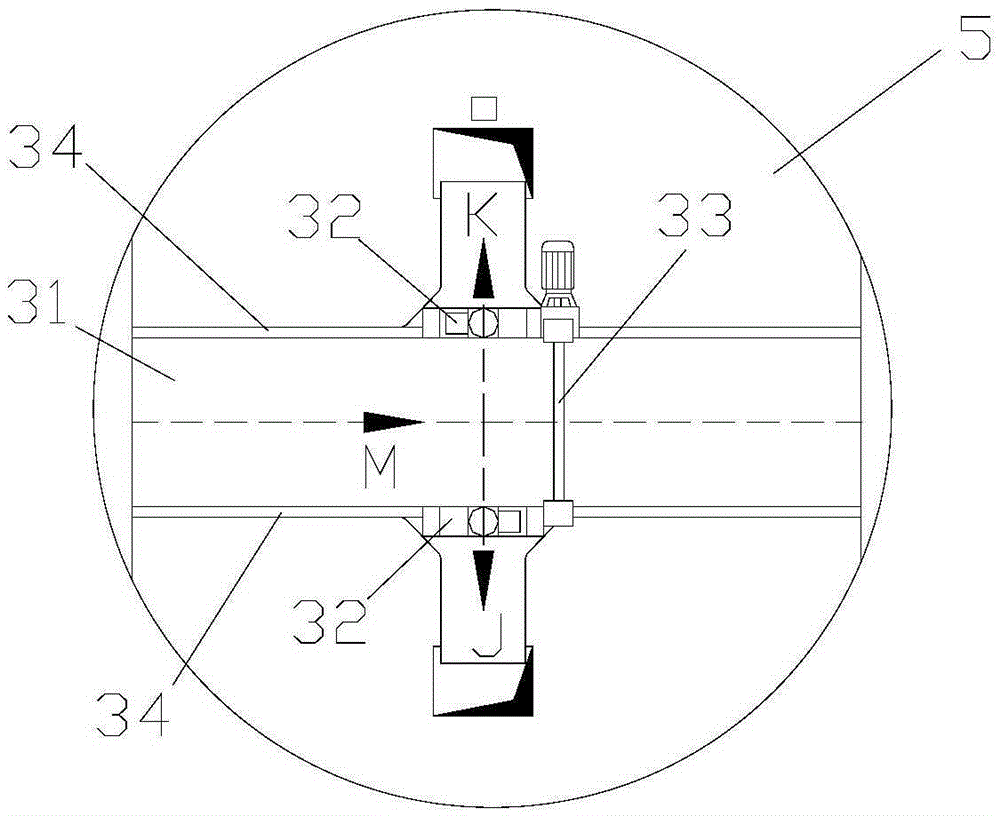

[0054] Figure 1 to Figure 7 Schematically shows the structure of a farming manure biological drying system in an embodiment of the present invention.

[0055] Such as Figure 1 to Figure 7 As shown, the breeding manure biological drying system in the farm includes a mixing system 1, a conveying system 2, an automatic batching system 3, an aeration system 4, a biological drying workshop 5, an exhaust system 6 and a deodorizing system 7.

[0056] Such as figure 1 As shown, the mixing system 1 uniformly mixes the collected breeding manure and auxiliary materials, and transports the mixed materials to the conveying system 2 .

[0057] In this embodiment, the mixing system 1 is implemented by a mixer to ensure that the breeding manure and auxiliary materials are evenly mixed. In other embodiments, the stirring system 1 can also be realized by manual stirring,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com