Anti-collision system and method of bulk cargo storage yard stand-alone equipment

An anti-collision, stand-alone technology, applied in the field of three-dimensional positioning, can solve problems such as less than 5 years, reduce work efficiency, affect production operations, etc., achieve accurate cantilever rotation on the same side, meet the effect of accurate positioning and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0038] The structure of the stand-alone equipment positioning and anti-collision system in the bulk cargo port yard described in the present invention is:

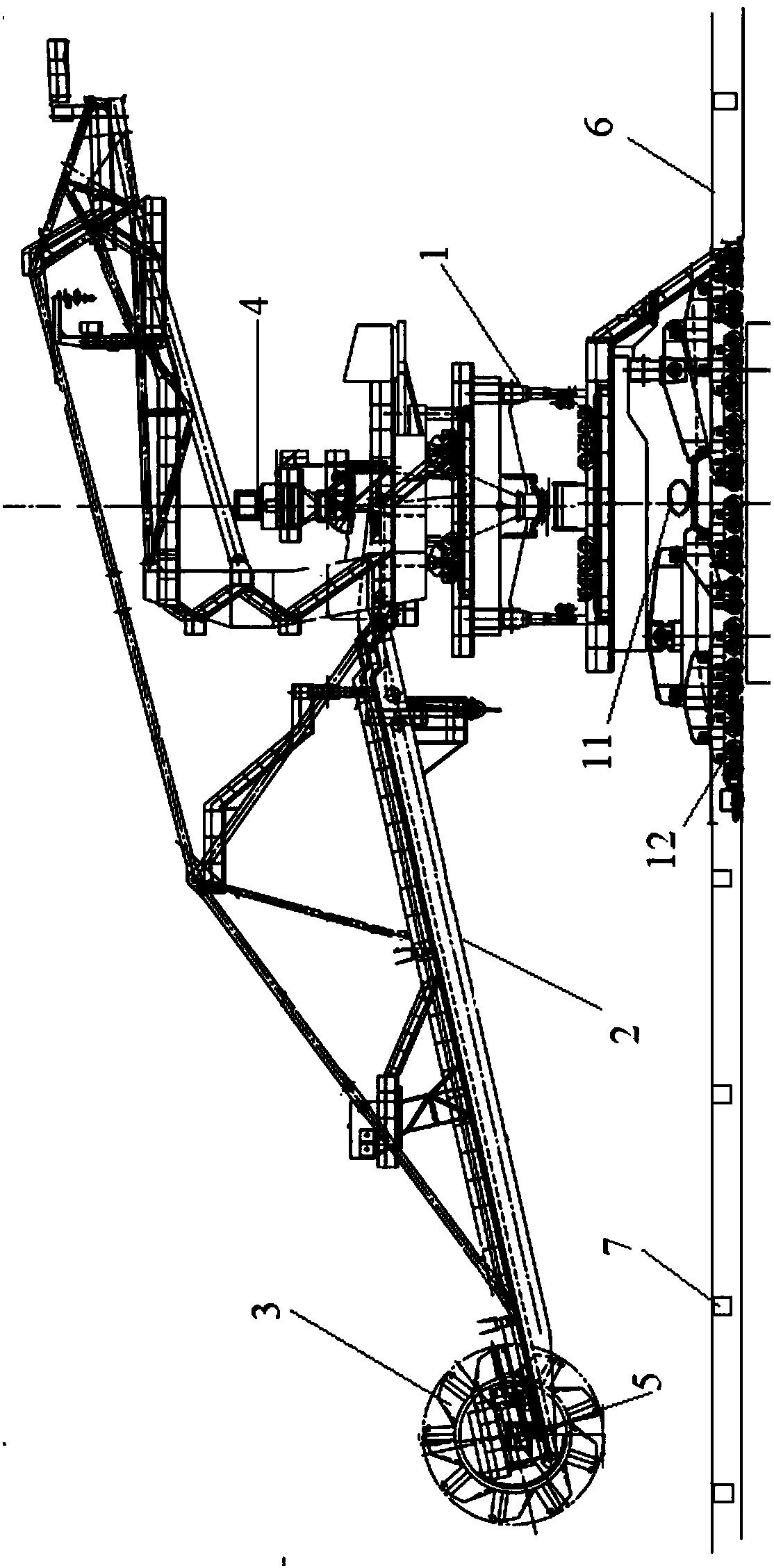

[0039] Such as figure 1 As shown, a bulk cargo port yard stand-alone equipment anti-collision system is characterized in that it includes:

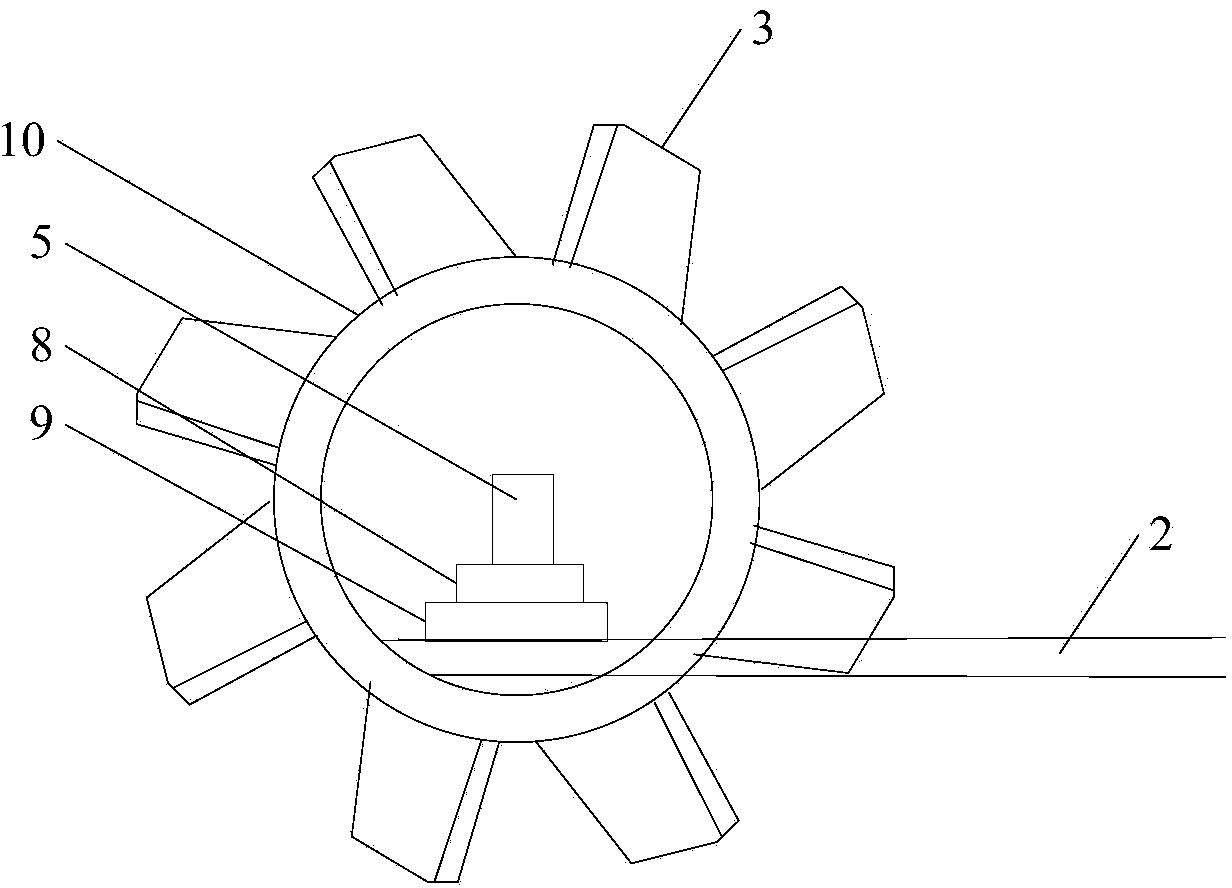

[0040] Stand-alone equipment, which includes: a traveling mechanism 12, which is arranged at the bottom of the stand-alone equipment; a cantilever bracket 1, which is arranged on the traveling mechanism 12; a cantilever 2, one end of which is pivotally connected to the cantilever bracket 1; a reclaimer 3. It is pivotally connected to the other end of the cantilever 2. The reclaimer 3 is a reclaiming device that rotates a plurality of hoppers relative to the pivot shaft. A through ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com