Car roof device and low floor tramcar

A technology of roof side beams and layer panels, which is applied in the direction of trams, railway roofs, transport passenger cars, etc., can solve the problems of no drainage structure on the roof, small load on the roof, and unsatisfactory use, so that it is not easy to deform , reduce overall weight, and facilitate production and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

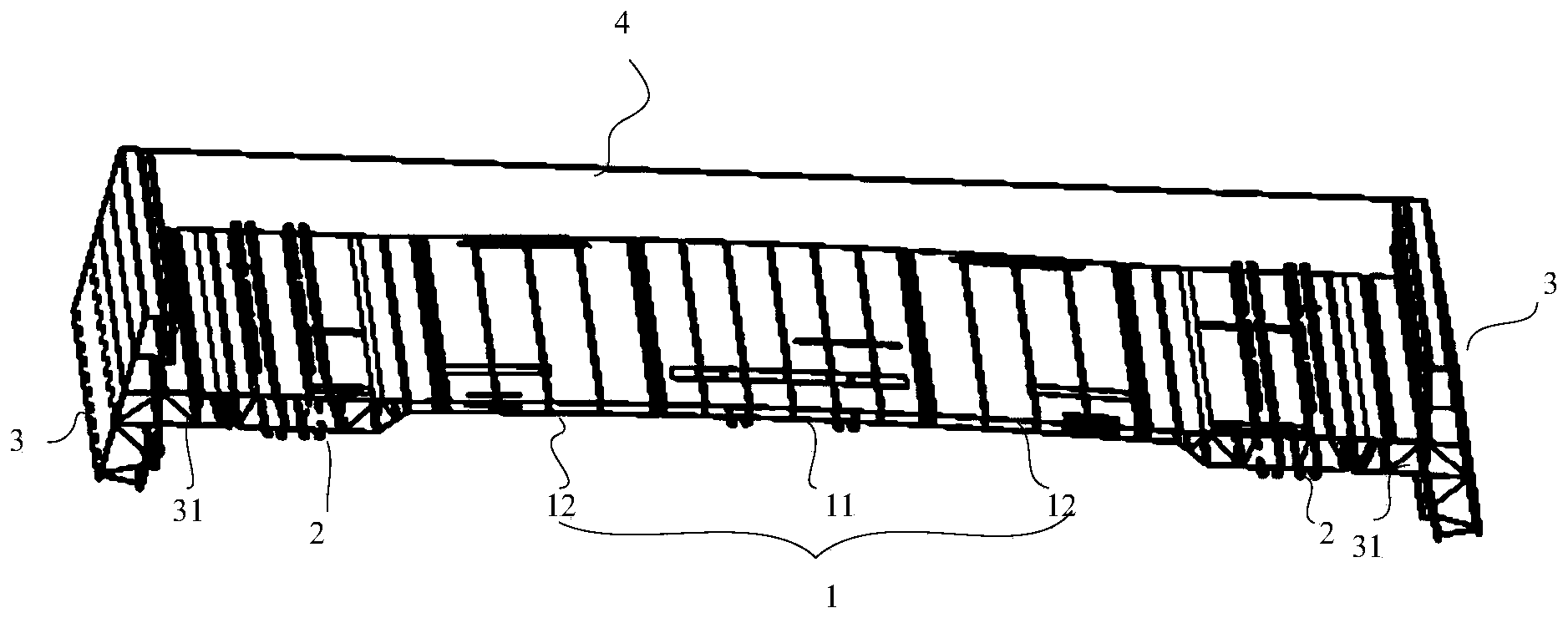

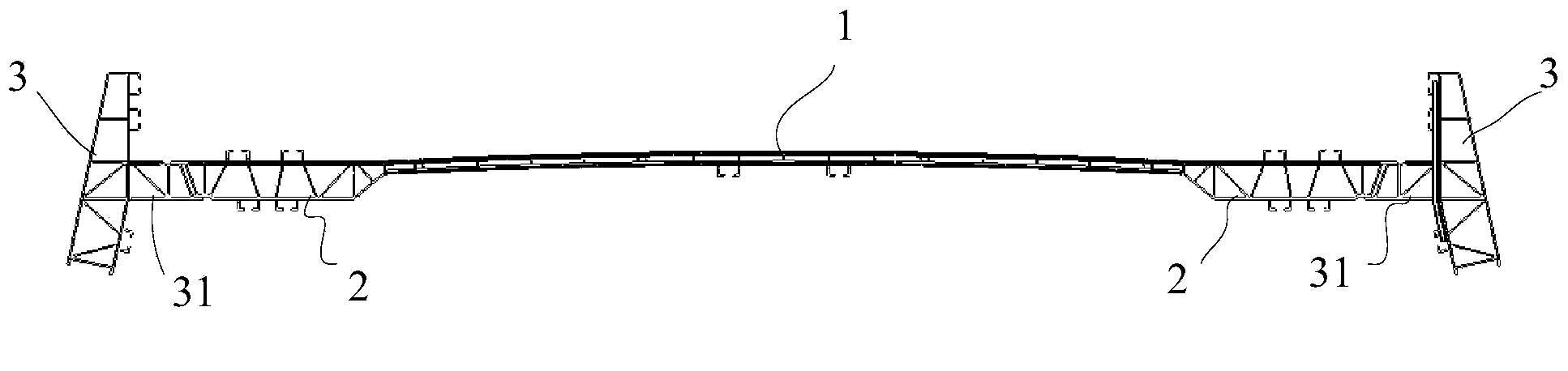

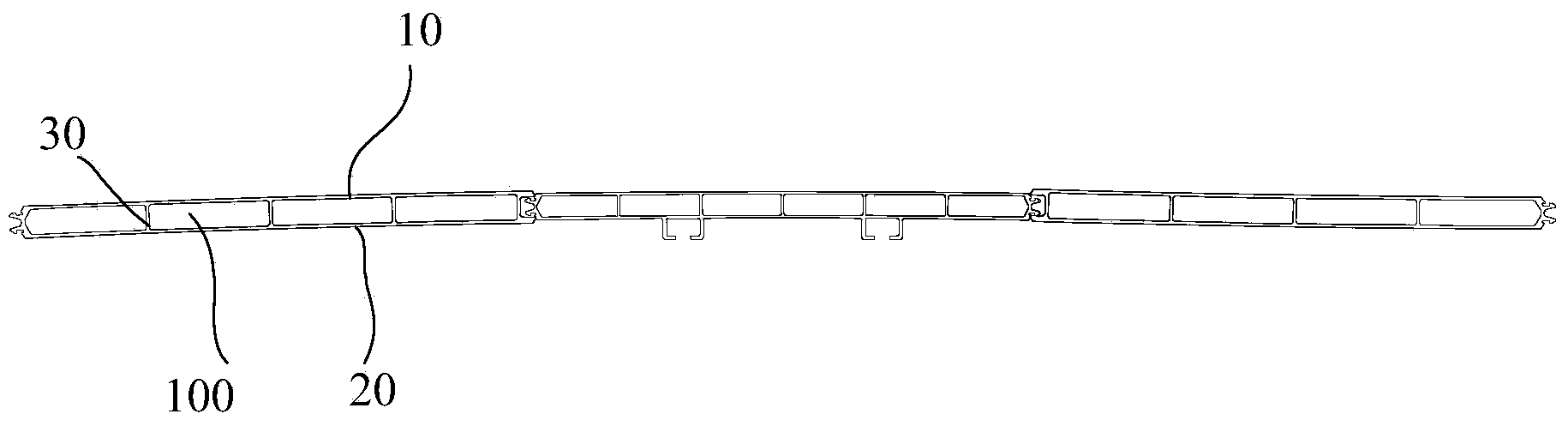

[0043] Such as Figure 1-6 As shown, the embodiment of the present invention provides a low-floor tram roof device, which includes an arc profile 1, two plane profiles 2, two roof side beams 3 and two car top end beams 4; the arc profile 1 is along the width direction The cross-section is arc-shaped, and each side along the length direction is connected to one side of the plane profile 2 along the length direction; The sides are respectively connected to a roof side rail 3; the cross-section of the two roof side rails 3 along the width direction is T-shaped, and the lateral overhang 31 of each roof side rail 3 along the side of the length direction Both are connected to the side of a planar profile 2 along the length direction; one side of each roof beam 4 along the length direction is connected to one end of the whole formed by the curved profile 1, two planar profiles 2, and two roof side rails 3; The arc profile 1, the plane profile 2, the roof side beam 3 and the vehicle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com