Feeding platform of inkjet coding machine

A technology of feeding platform and coding machine, which is applied in the direction of printing device, printing, etc., which can solve the problems of coding deviation, information coding area not directly below the nozzle, and poor initial placement of the conveyor belt, etc., to achieve good accuracy , Conducive to the effect of coding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

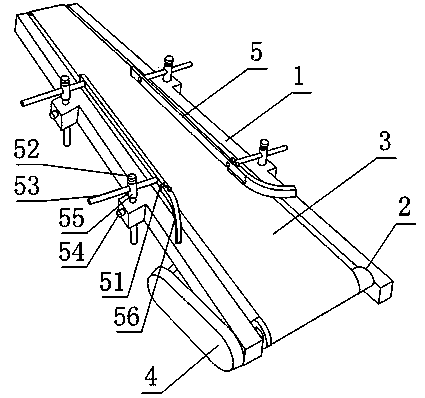

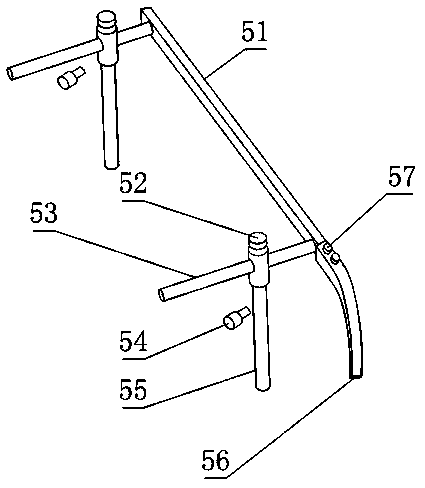

[0023] Such as figure 1 and figure 2 , the inkjet coding machine feeding platform provided by the present invention includes a platform frame 1, and the platform frame 1 is provided with at least two pulleys 2 parallel to each other, and a conveyor belt 3 is wound on the pulley 2. Two stoppers 5 on the frame 1 and located on different sides of the conveyor belt 3, the stoppers 5 include bar-shaped or plate-shaped stoppers 51 perpendicular to the axis of the pulley 2, and the stoppers 51 are fixedly connected with the axis A horizontal slide bar 53 parallel to the axis of the belt pulley 2, the platform frame 1 is also provided with a through hole whose axis is in the vertical direction, and the through hole is provided with a column 55 that fits with it in a clearance, and the platform frame 1 is also provided with a It is a height adjusting bolt 54 that is threaded, and the threaded end of the height adjusting bolt 54 is in contact with the column 55, and a slide bar hole i...

Embodiment 2

[0027] This embodiment is further limited on the basis of embodiment 1: as figure 1 and figure 2, in order to reduce the possibility that the extension length of the stopper 51 relative to the column 55 and the angle between the two will change automatically when the stopper 51 produces a pressing force with the packaging box, the horizontal slide on the limit device 5 There are two rods 53 , columns 55 , width adjustment bolts 52 and height adjustment bolts 54 , and two horizontal sliding rods 53 are respectively fixed at one end of the block 51 . The above setting makes any horizontal slide bar 53 all unable to rotate in the slide bar hole, and any horizontal slide bar 53 on the same block 51 is dependent on the sliding of another horizontal slide bar 53 relative to the column 55 connected thereto. Exercise to achieve the above technical effects.

Embodiment 3

[0029] This embodiment is further limited on the basis of embodiment 1: as figure 1 and figure 2 , also includes a pulley brake part 4, the pulley brake part 4 includes a motor and a belt, and the belt is wound between any one pulley 2 and the rotor of the motor. The provided pulley braking part 4 is used to brake the movement of the conveyor belt 3, and the structural form of a belt drive is adopted between the motor and the pulley 2, which has low cost, can obtain a large transmission ratio and prevents the conveyor belt 3 from jamming when the conveyor belt 3 is jammed. , the belt can protect the conveyor belt 3, the pulley 2 or the packing box by slipping.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com