Plastic-wood composite panel for packaging steel coils and preparation method thereof

A technology of composite board and plastic wood, which is applied in packaging, wrapping paper, transportation and packaging, etc. It can solve the problems of high production cost, easy damage, poor corrosion performance, etc., and achieve the effect of cost reduction, ideal effect and firm plastic layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

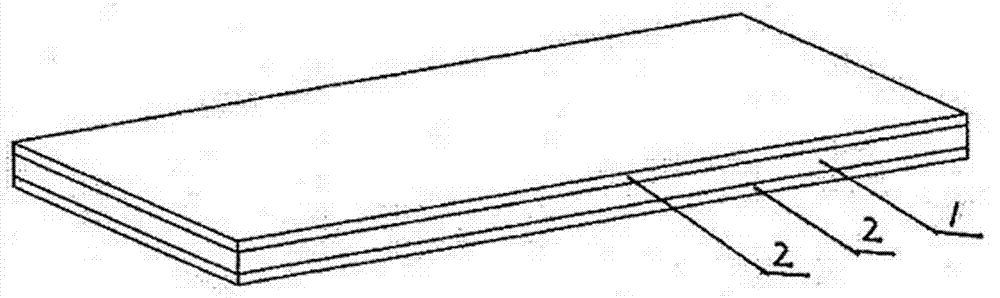

[0017] see figure 1 , which shows the appearance structure of an embodiment of the plastic-wood composite board for packaging steel coils proposed by the present invention. The plastic-wood composite board is composed of a fiber substrate 1 and a plastic layer 2 arranged on the surface of the fiber substrate 1, wherein the plastic layer 2 is composited on the surface of the fiber substrate 1 by casting and calendering methods, and the plastic layer 2 can be composited on the fiber substrate. One surface or both upper and lower surfaces of the substrate 1, figure 1 A structure is shown in which the upper and lower surfaces of the fiber substrate 1 are respectively compounded with plastic layers 2 . The fiber substrate 1 is made of medium density board or hard fiberboard or cardboard or straw fiberboard, the thickness of the fiber substrate 1 is 1.5-6 mm, preferably 4 mm, and the thickness of the plastic layer 2 is 0.2-0.6 mm, preferably is 0.4mm.

[0018] In the proce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com