Fixing device for braking calipers needing to be tested through liquid measurement rack

A technology for brake caliper and bench testing, which is applied in the testing of measuring devices, workpiece clamping devices, and mechanical parts, etc., and can solve problems such as inconsistency, obvious shaking of brake calipers, and inaccurate fluid demand test data. Guaranteed accuracy and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

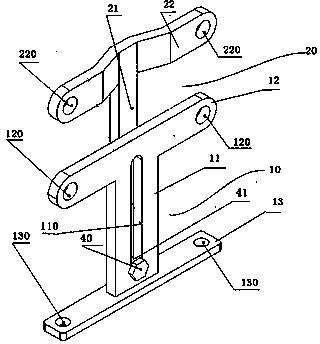

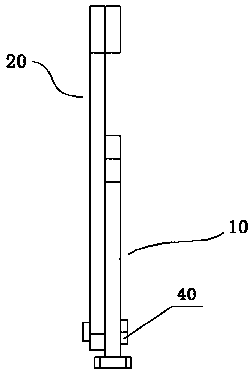

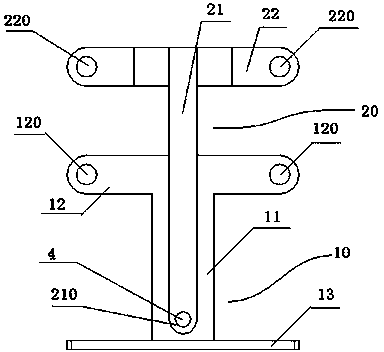

[0017] see figure 1 , figure 2 and image 3 , the fixing device of the brake caliper of the fluid demand bench test of the present invention comprises a lower frame 10 and an upper frame 20: from figure 1 It can be seen that the lower frame 10 is in an I-shape as a whole, and includes a vertical connecting portion 11 and a horizontal lower clamping portion 12 connected to the upper and lower ends of the connecting portion 11 and a base 13. The connecting portion 11 is provided with a There are longitudinal slots 110, the two ends of the lower clamping part 12 are provided with installation holes 120 for installing brake calipers, and the base 13 is assembled on the liquid demand test table; figure 1 , figure 2 and image 3 It can be seen that the upper frame 20 is T-shaped as a whole, including a vertical support portion 21 and a horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com