A combined machine tool

A technology of combining machine tools and machine bodies, which is applied in the field of special equipment for cutting and stamping of non-standard products, can solve the problems that small and medium-sized enterprises cannot afford equipment cost investment, restrict product quality, and have low positioning accuracy, and achieve easy assurance of the quality of processed products. Significant increase in yield and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

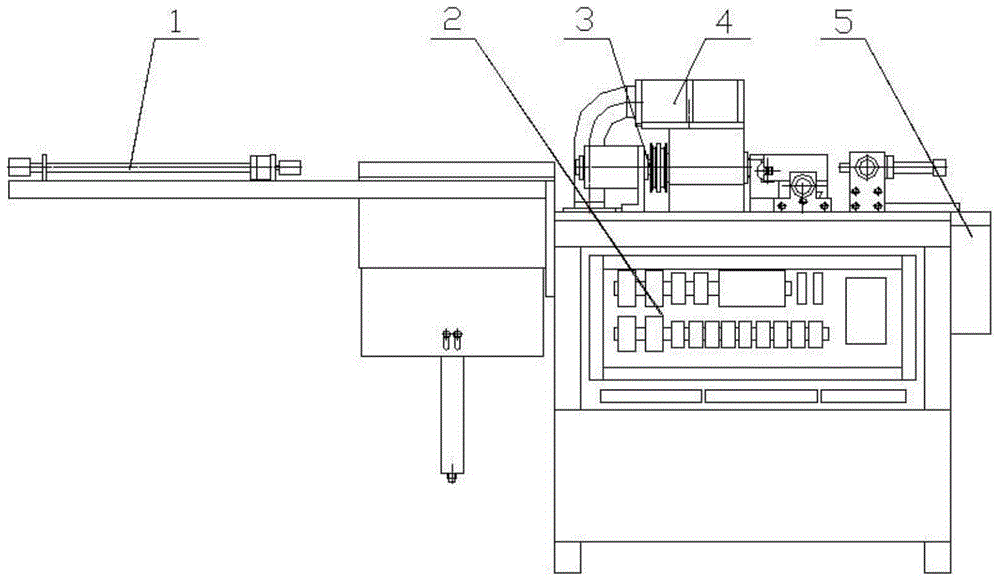

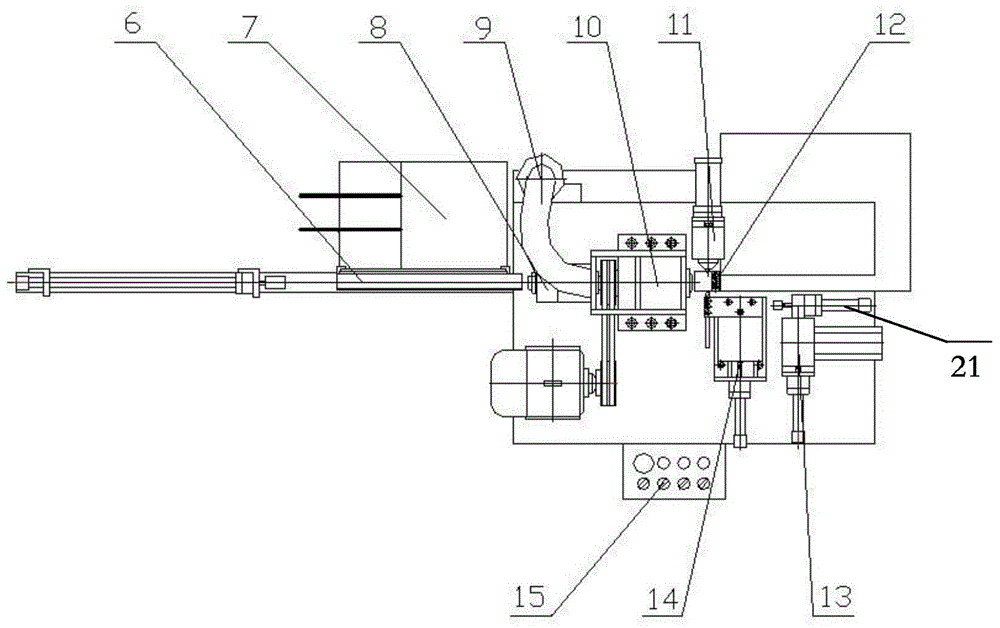

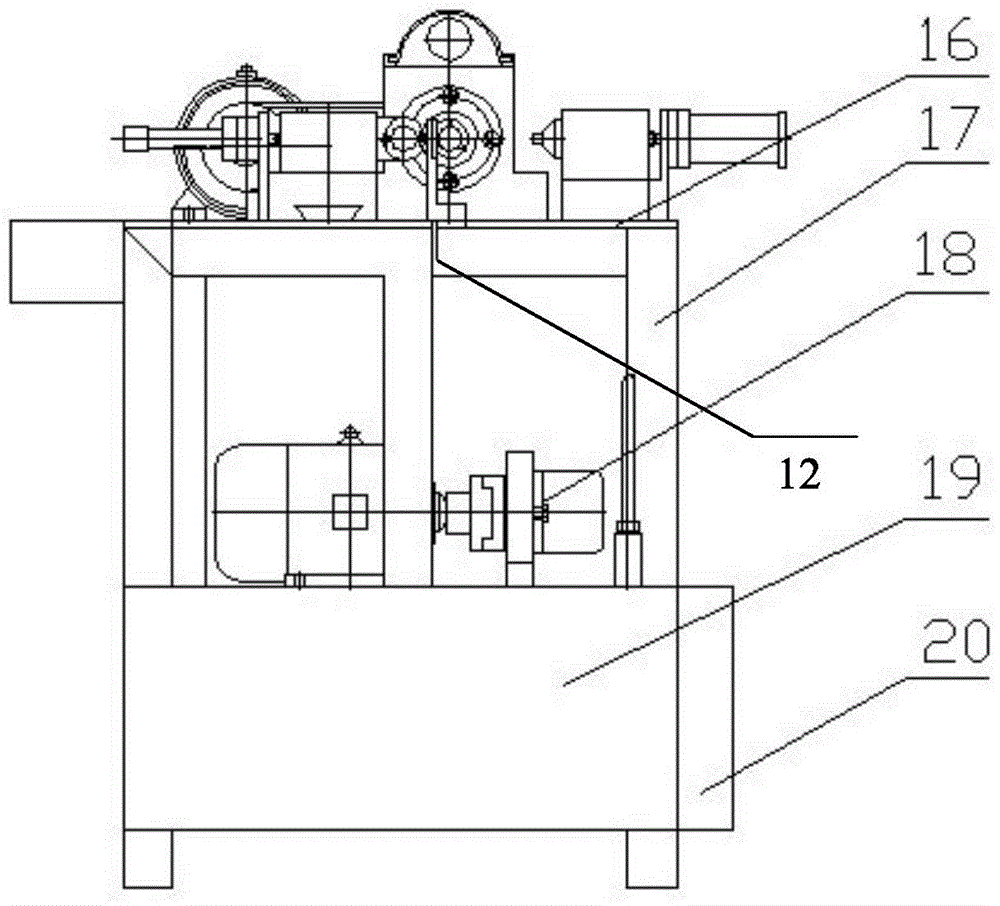

[0047] Such as figure 1 , figure 2 and image 3 As shown, the present invention provides a combination machine tool, comprising:

[0048] Body, including frame 17 and workbench 16;

[0049] a rotary clamping mechanism defining a horizontal machining axis;

[0050] A cutting mechanism 14, which is arranged on the machine body and on one side of the machining axis;

[0051] A punching mechanism 11, which is arranged on the body and on one side of the processing axis; the punching direction of the punching mechanism 11 is a horizontal direction;

[0052] (Wherein, stamping mechanism 11 and cutting mechanism 14 can be positioned at the same side or both sides of machining axis, as figure 1 As shown in , the stamping mechanism 11 and the cutting mechanism 14 are located on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com