A fixture for ultrasonic perturbation electrolyte microporous electrolytic machining

A technology of electrolyte and jig, which is applied in the field of micro-electrolytic machining jigs, and can solve problems affecting the machining process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

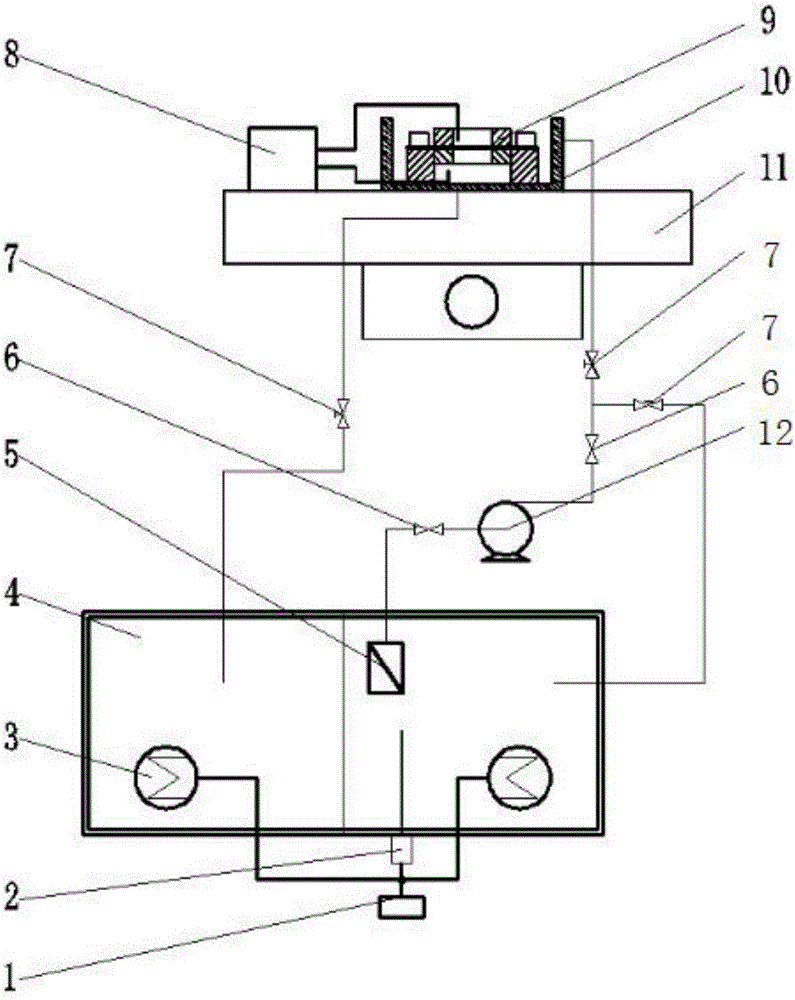

[0019] Such as figure 1 As shown, the ultrasonic disturbance electrolyte micro electrolytic processing system mainly consists of two parts, including temperature controller 1, thermocouple 2, heater 3, electrolyte tank and electrolyte 4, filter 5, check valve 6, ball valve 7. Electrolyte tank 10, multi-stage centrifugal pumps and pipelines constitute the electrolyte circulation system of the machine tool, supplying electrolyte for processing and discharging electrolytic products. The heater 3 is controlled by the thermocouple 2 and the temperature controller 1 to heat the electrolyte in the liquid tank 4 .

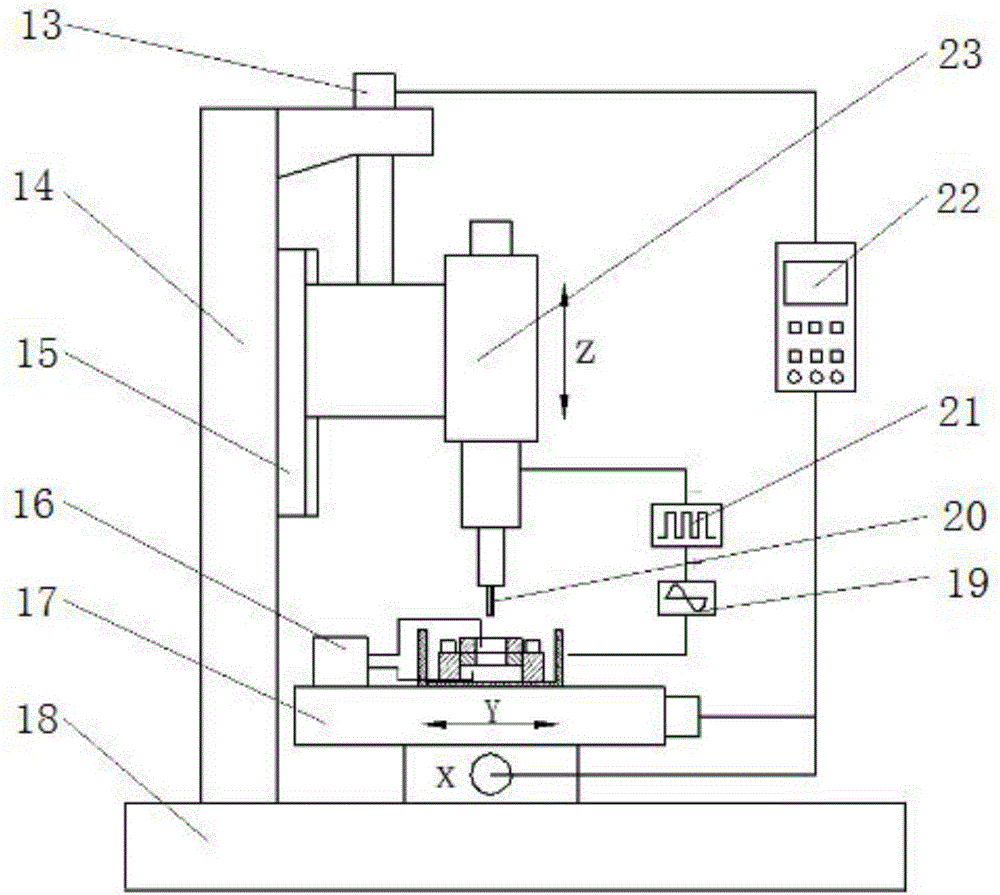

[0020] Such as figure 2 As shown, the machine tool column 14, the guide rail 15, and the marble base 18 in the whole machine tool for ultrasonically disturbing the electrolyte micro-electrolytic machining form the main body of the machine tool. The Z-axis stepping motor 13, the XY workbench 17, the controller 22, and the machine tool spindle 23 form the motion control s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com