An inner locking push knife

An internal locking and tight technology, which is applied in the direction of broaching tools, broaching machines, metal processing equipment, etc., can solve the problem of large space occupation, and achieve the effect of small occupied space, long-lasting internal locking force and space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

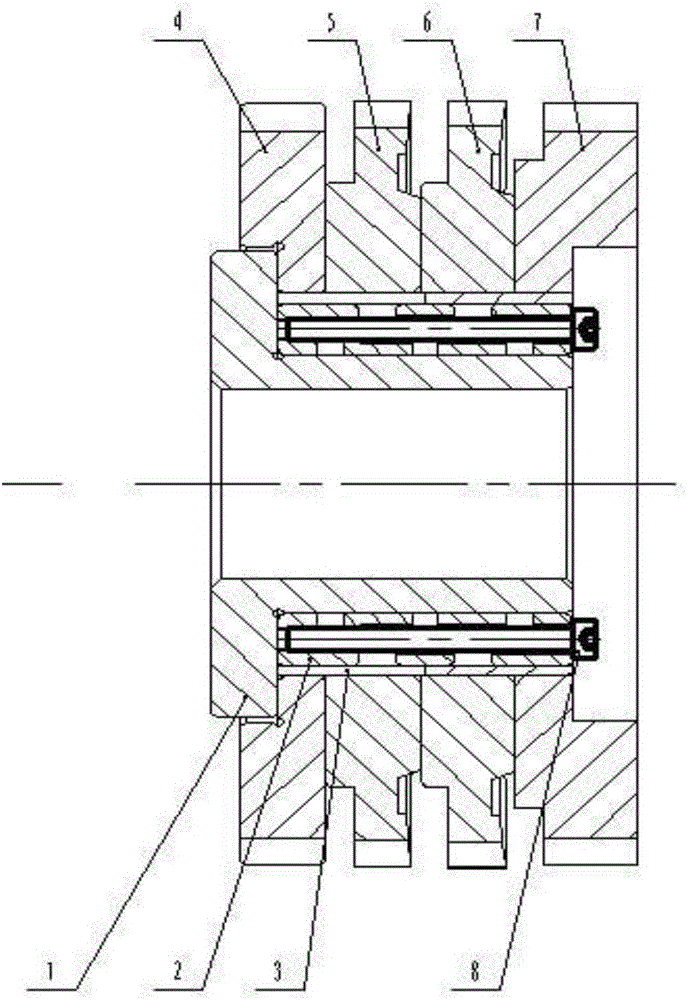

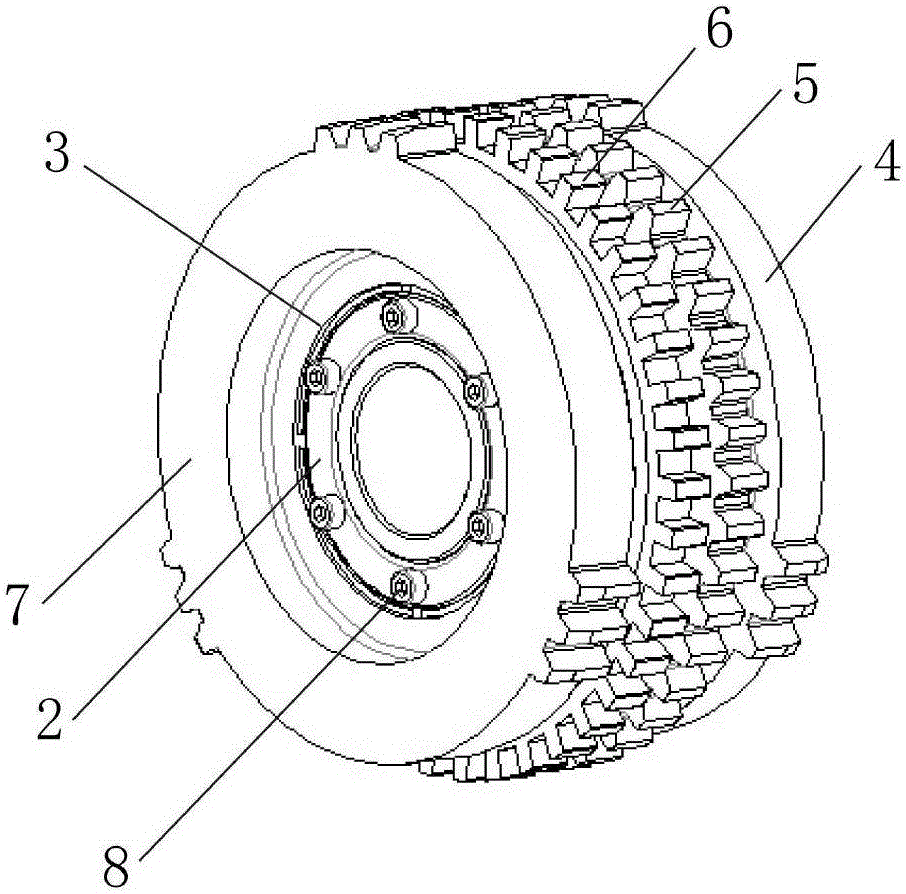

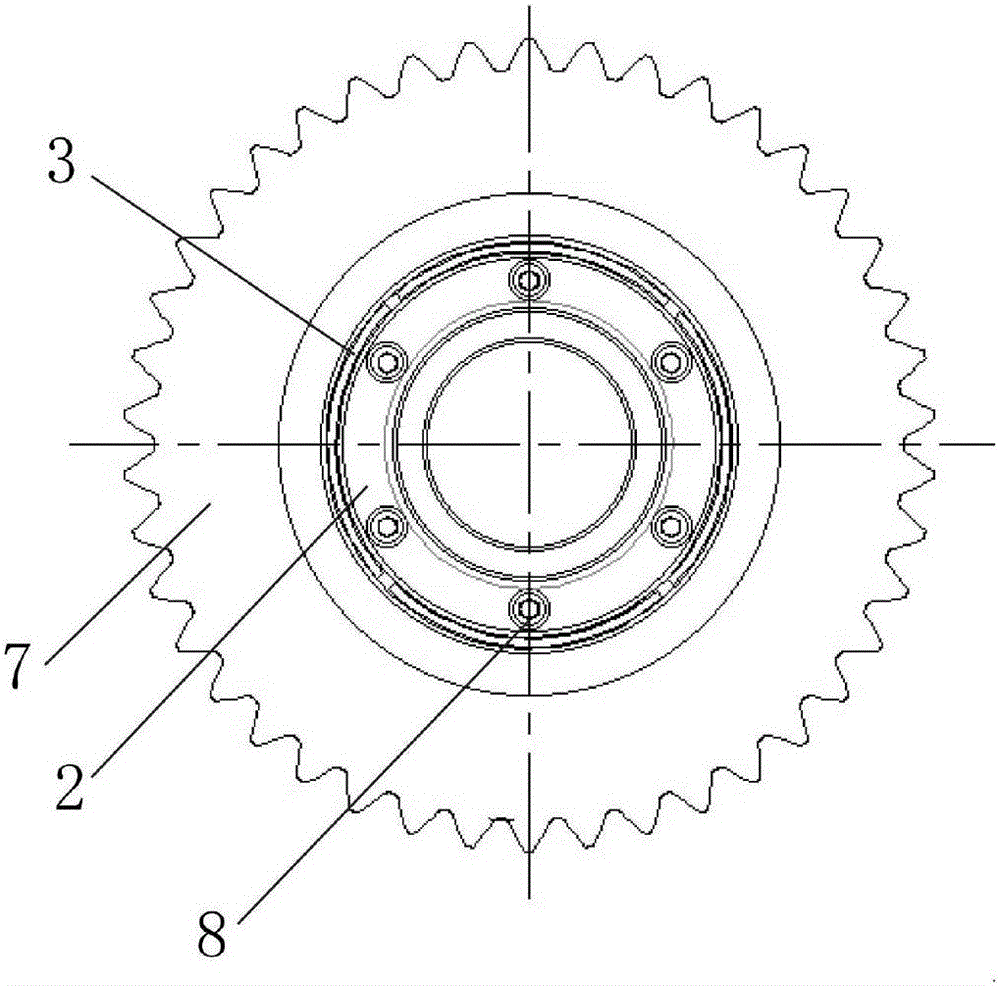

[0023] Specific embodiments of the invention will be described in detail below in conjunction with the accompanying drawings.

[0024] Such as figure 1 As shown, the inner locking push knife includes the expansion core 2, the expansion sleeve 3 and the locking bolt 8. The expansion sleeve 3 is set on the outside of the expansion core 2, and the outside of the expansion sleeve 3 is set with a rear guide from left to right. Part 4, spline push knife 5, rectangular spline 6 and front guide 7, the left end of the through hole at the central axis of the expansion core 2 is assembled on the support seat 1, and the end surface on the right side of the expansion core 2 is provided with an axial And the screw holes arranged in an annular array, the locking bolts 8 are screwed into the screw holes.

[0025] The support seat 1 is connected with the machine tool, and the locking bolt 8 is screwed in from the right side of the expansion core, the expansion core 2 continues to expand, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com