Preparation method for metal-organic framework nanoparticle material with mesoporous structure

A technology of organic framework and mesoporous structure is applied in the field of preparation of metal-organic framework nanoparticle materials, which can solve the problems of difficult preparation of mesoporous structure and large particle size of materials, and achieve the effect of high specific surface area and large adsorption capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

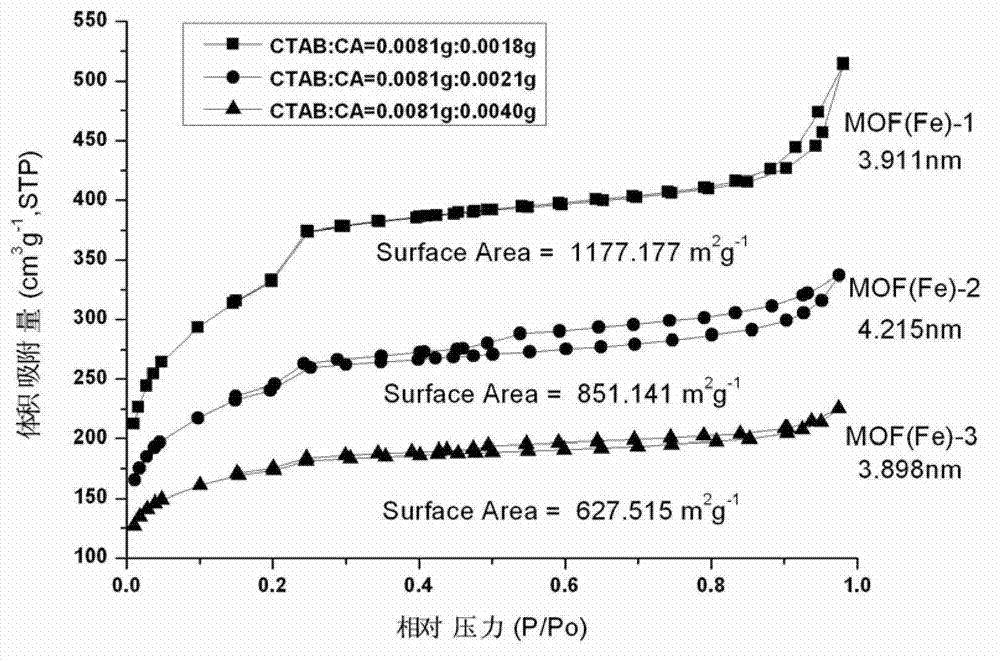

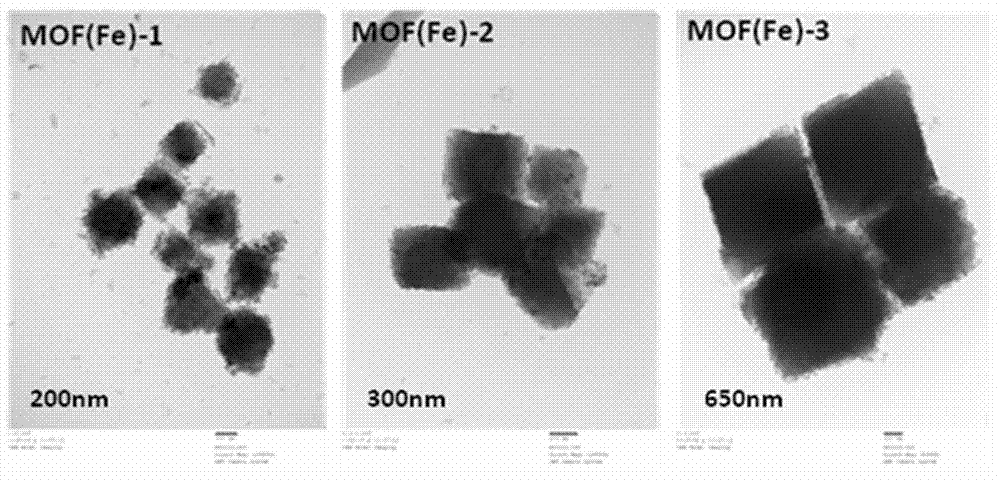

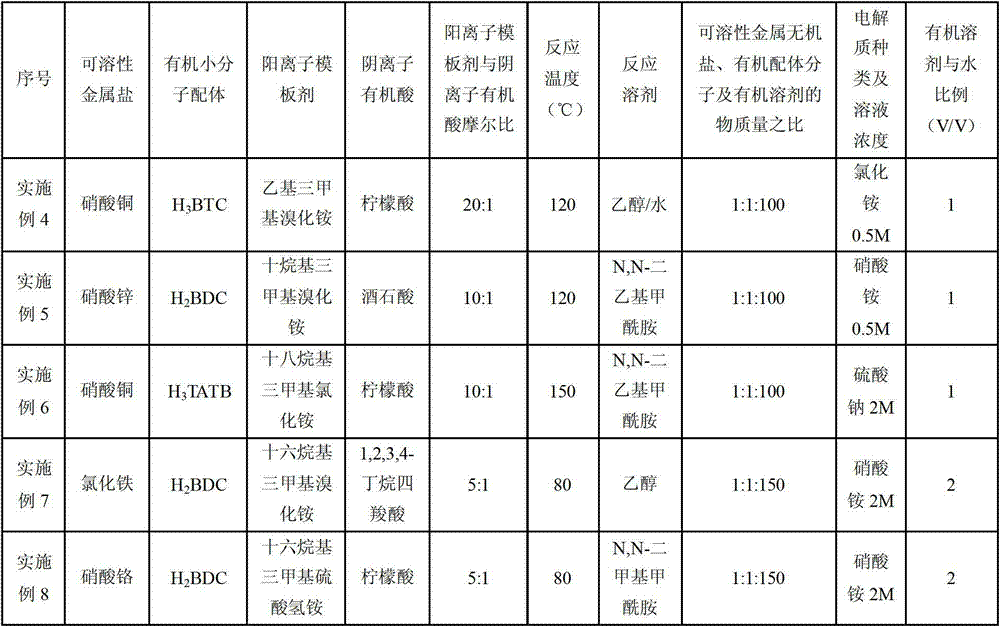

[0028] 1. Dissolve 0.0081g of CTAB and 0.0018g of CA mixture (the molar ratio of CTAB and CA is 2.3) in 25mL of N,N-dimethylformamide, sonicate for 10min to fully dissolve.

[0029] 2. Slowly add 0.6758g of ferric chloride hexahydrate and 0.4150g of 1,4-terephthalic acid into the above solution, and continue to sonicate until a uniform and transparent solution is obtained. (The ratio of soluble metal inorganic salts, organic ligand molecules and organic solvents is 1:1:129).

[0030] 3. Put the transparent solution obtained in 2 into the hydrothermal reaction kettle, and react at 75°C for 96h.

[0031] 4. After the reaction, centrifuge the reaction solution to remove the N,N-dimethylformamide reaction solution.

[0032] 5. The crude product was then washed twice with N,N-dimethylformamide to remove unreacted raw materials.

[0033] 6. Use 1M ammonium nitrate in ethanol / water (V / V=1:2) solution to ion-exchange the solid obtained in 5 at 60°C for 24 hours to remove the templat...

Embodiment 2

[0036] 1. Dissolve 0.0081g of CTAB and 0.0021g of CA mixture (the molar ratio of CTAB and CA is 2.03) in 25mL of N,N-dimethylformamide, sonicate for 10min to fully dissolve.

[0037]2. Slowly add 0.6758g of ferric chloride hexahydrate and 0.4150g of 1,4-terephthalic acid into the above solution, and continue to sonicate until a uniform and transparent solution is obtained.

[0038] 3. Put the transparent solution obtained in 2 into the hydrothermal reaction kettle, and react at 75°C for 96h.

[0039] 4. After the reaction, centrifuge the reaction solution to remove the N,N-dimethylformamide reaction solution.

[0040] 5. The crude product was then washed twice with N,N-dimethylformamide to remove unreacted raw materials.

[0041] 6. Use 1M ammonium nitrate in ethanol / water (V / V=1:2) solution to ion-exchange the solid obtained in 5 at 60°C for 24 hours to remove the template agent.

[0042] 7. Finally, wash the product removed from the template agent in 6 with ethanol / water s...

Embodiment 3

[0044] 1. Dissolve 0.0081g of CTAB and 0.0040g of CA mixture (the molar ratio of CTAB and CA is 1.15) in 25mL of N,N-dimethylformamide, sonicate for 10min to fully dissolve.

[0045] 2. Slowly add 0.6758g of ferric chloride hexahydrate and 0.4150g of 1,4-terephthalic acid into the above solution, and continue to sonicate until a uniform and transparent solution is obtained.

[0046] 3. Put the transparent solution obtained in 2 into the hydrothermal reaction kettle, and react at 75°C for 96h.

[0047] 4. After the reaction, centrifuge the reaction solution to remove the N,N-dimethylformamide reaction solution.

[0048] 5. The crude product was then washed twice with N,N-dimethylformamide to remove unreacted raw materials.

[0049] 6. Use 1M ammonium nitrate in ethanol / water (V / V=1:2) solution to ion-exchange the solid obtained in 5 at 60°C for 24 hours to remove the template agent.

[0050] 7. Finally, wash the product removed from the template agent in 6 with ethanol / water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Mesopore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com