Novel dimeric cationic surfactant and preparation method thereof

A surfactant and cation technology, applied in chemical instruments and methods, dissolution, organic chemistry, etc., can solve the problems of few varieties and high price of gemini surfactants, achieve low surface tension, good water solubility, and broad application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] One, the preparation of intermediate B

[0028] Dissolve 0.114mol (9.9g) of anhydrous piperazine and 18ml (0.228mol) of epichlorohydrin in a mixture of 50ml of ethanol and water (volume ratio 4:1) (indicate that the amount used can be dissolved.), 50°C Heated for 48 hours, cooled to room temperature, washed with acetone, filtered with suction, and dried under vacuum at 40°C to obtain intermediate product B. Yield 60%.

[0029]

[0030] Structural characterization of the intermediate: The mass spectrometer showed that the molecular ion peak MS271.1 was the main peak, indicating that intermediate B was synthesized.

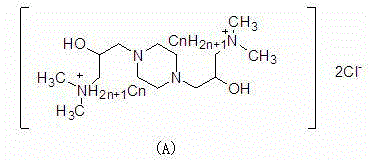

[0031] Two, the preparation of cationic gemini surfactant A

[0032] Dissolve 0.01mol B (2.71g) and 0.02mol (5.94g) of dimethyloctadecylamine in 50ml of n-propanol (note that the amount used can be dissolved.), heat at 90°C for 15h, cool to room temperature, distilled water Wash, filter with suction, and dry under vacuum at 40°C to obtain Gemini surfact...

Embodiment 2

[0046] 1. Preparation of intermediates

[0047] 0.114mol (9.9g) of anhydrous piperazine and 22.5ml (0.285mol) of epichlorohydrin are dissolved in a mixture of 50ml of ethanol and water (volume ratio 4:1) (indicate that the amount used can be dissolved.), 50 It was heated at °C for 48 hours, cooled to room temperature, washed with acetone, filtered with suction, and dried in vacuum at 40 °C to obtain intermediate product B. Yield 65%.

[0048] 2. Preparation of Cationic Gemini Surfactants

[0049] Dissolve 0.01mol B (2.71g) and 0.02mol (5.94g) of dimethyloctadecylamine in 50ml of n-propanol (note that the amount used can be dissolved.), heat at 90°C for 15h, cool to room temperature, distilled water Washing, suction filtration, and vacuum drying at 40° C. to obtain Gemini surfactant A, wherein n=18. Yield 81%.

Embodiment 3

[0051] 1. Preparation of intermediates

[0052]Dissolve 0.114mol (9.9g) of anhydrous piperazine and 27ml (0.342mol) of epichlorohydrin in a mixture of 50ml of ethanol and water (volume ratio 4:1) (note that the amount used can be dissolved.), 50°C Heated for 48 hours, cooled to room temperature, washed with acetone, filtered with suction, and dried under vacuum at 40°C to obtain intermediate product B. Yield 68%.

[0053] 2. Preparation of Cationic Gemini Surfactants

[0054] Dissolve 0.01mol B (2.71g) and 0.02mol (5.94g) of dimethyloctadecylamine in 50ml of n-propanol (note that the amount used can be dissolved.), heat at 90°C for 15h, cool to room temperature, distilled water Washing, suction filtration, and vacuum drying at 40° C. to obtain Gemini surfactant A, wherein, n=18, yield 81%.

PUM

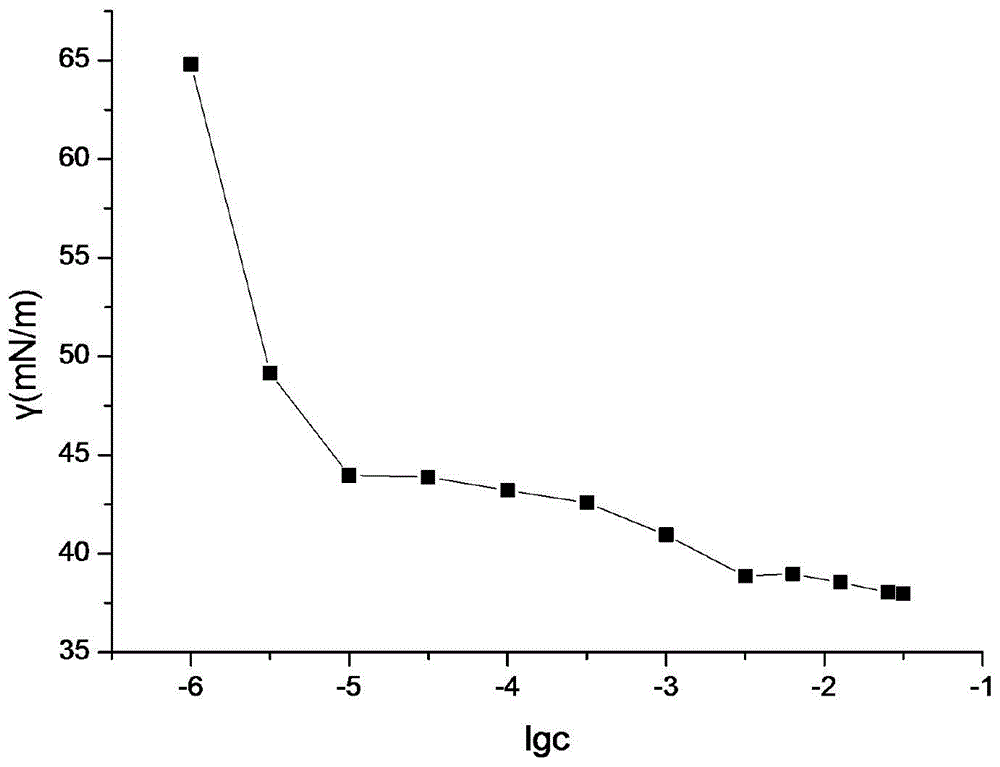

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com