Composite busbar and three-phase inverter circuit

A composite busbar and busbar technology, applied in circuits, printed circuit board sockets, coupling devices, etc., can solve the problem of large stray inductance, reduce stray inductance, reduce peak voltage generation, and simple circuit layout Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

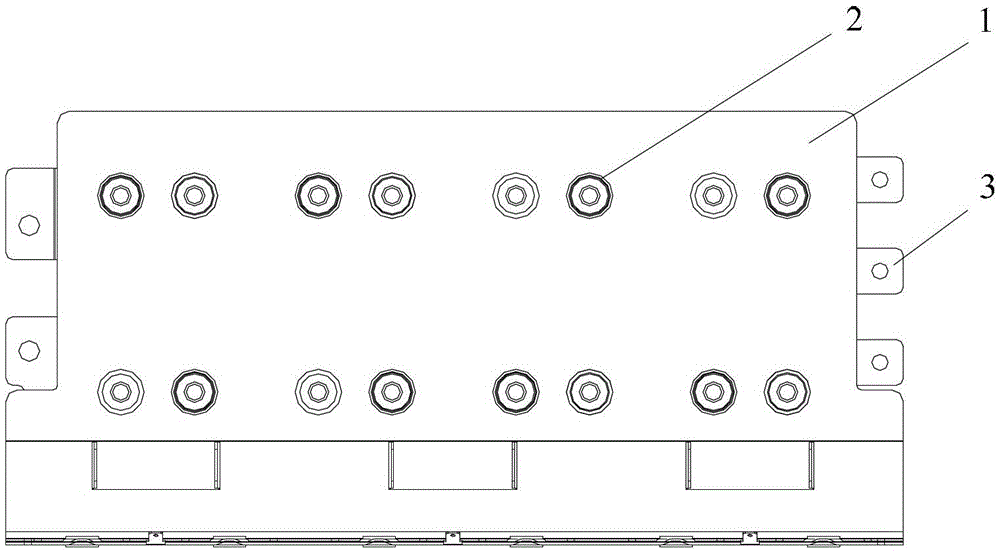

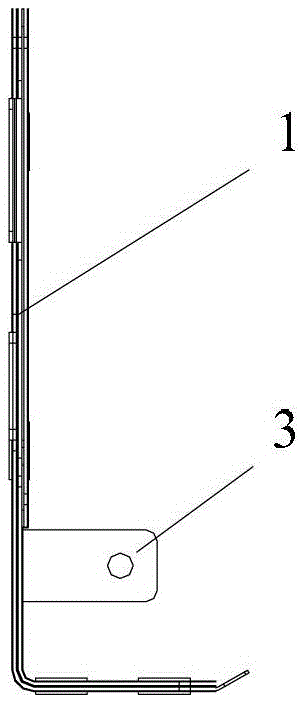

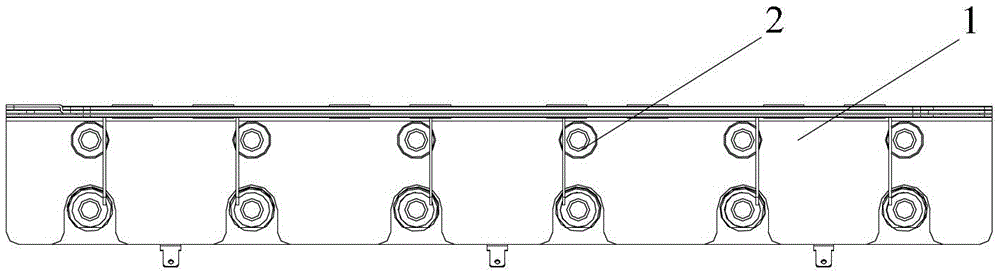

[0022] figure 1 It is the front view of the composite busbar provided by Embodiment 1 of the present invention, figure 2 It is the left view of the composite busbar provided by Embodiment 1 of the present invention, image 3 It is a top view of the composite busbar provided by Embodiment 1 of the present invention. The specific structure of the composite busbar is as follows, including busbar 1 , terminal 2 and connection part 3 .

[0023] The shape of the busbars 1 is flat, at least two of the busbars 1 are stacked together, and the adjacent busbars 1 are filled with high-dielectric-strength materials, so that the gap between the adjacent busbars 1 Keep it insulated. Terminals 2 are arranged on the busbar 1 for connecting circuit devices. The connection part 3 is arranged on the bus bar 1 and is used for connecting a DC input terminal or a circuit device.

[0024] Wherein, the busbar 1 is set in a flat shape, the width of the section is increased, and the thickness of t...

Embodiment 2

[0031] Figure 4 It is a three-dimensional schematic diagram of the composite busbar provided in Embodiment 2 of the present invention, Figure 5 It is a three-dimensional schematic diagram of the composite busbar provided in Embodiment 2 of the present invention, Figure 6 for Figure 4 A schematic diagram of part A, Figure 7 for Figure 4 Part B schematic, Figure 8 The schematic diagram of the three-phase inverter circuit provided by Embodiment 2 of the present invention. This embodiment further optimizes the technical solution of applying the composite busbar to the three-phase inverter circuit on the basis of the above embodiments. The three-phase inverter circuit includes three sets of power devices, energy storage devices, discharge resistors and composite busbars.

[0032] Wherein, the composite busbar is the composite busbar mentioned in the above-mentioned embodiment, and the composite busbar includes three busbars stacked together, and the first busbar 11 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com