chopper circuit

A chopper circuit and busbar technology, which is applied in the direction of electrical components, adjusting electric variables, instruments, etc., can solve the problem of large stray inductance of the chopper circuit, improve flexibility, reduce peak voltage generation, and reduce volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

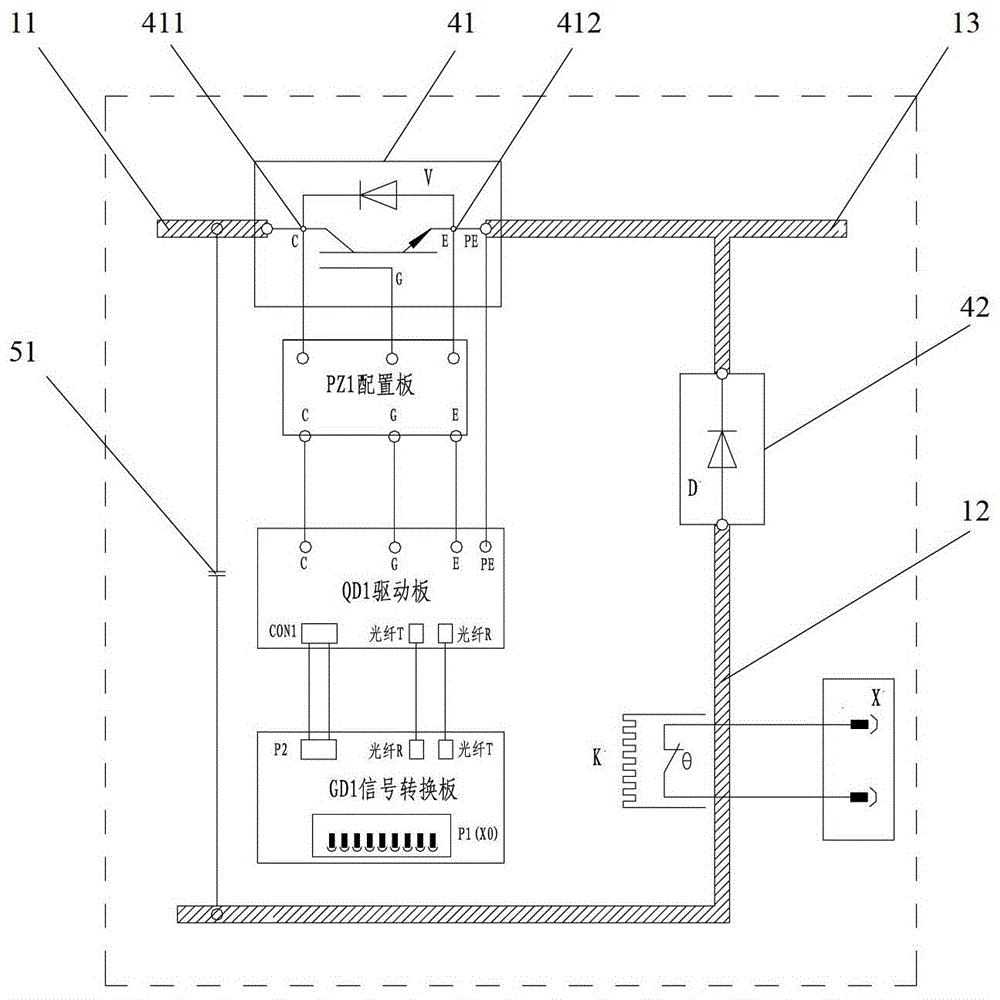

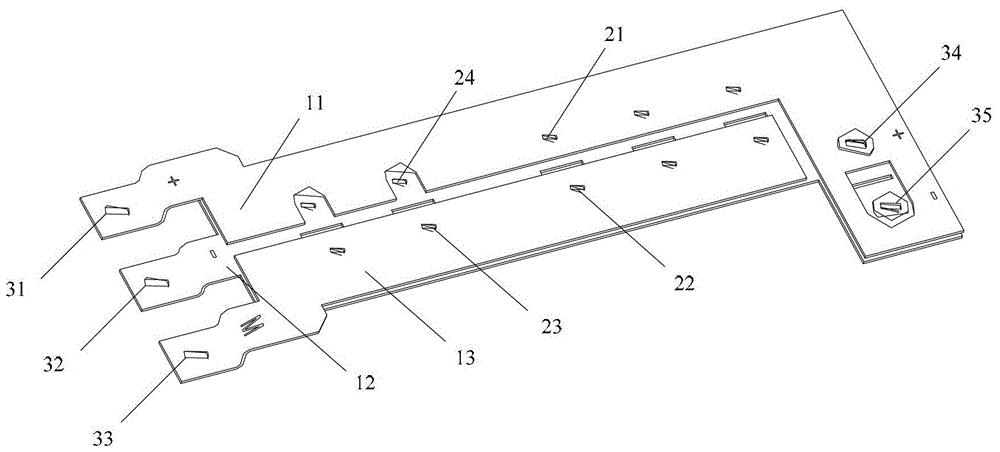

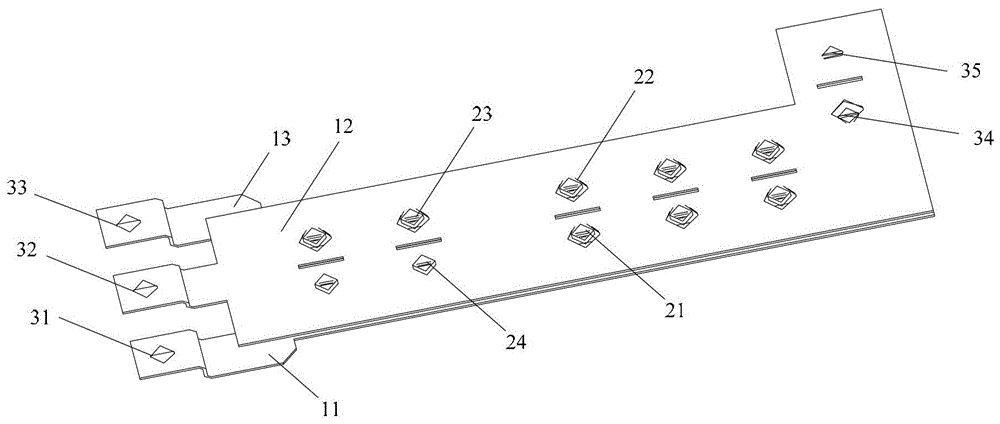

[0019] figure 1 A schematic structural diagram of a chopper circuit provided by an embodiment of the present invention, figure 2 A perspective view of one side of the composite busbar in the chopper circuit provided by the embodiment of the present invention, image 3 A perspective view of the other side of the composite busbar in the chopper circuit provided by the embodiment of the present invention, Figure 4 It is a schematic structural diagram of one side of the composite busbar in the chopper circuit provided by the embodiment of the present invention, Figure 5 for Figure 4 top view of Image 6 A schematic structural diagram of the other side of the composite busbar in the chopper circuit provided by the embodiment of the present invention. like Figure 1-6 As shown, the chopper circuit includes power devices, energy storage devices and composite busbars.

[0020] The composite busbar includes busbars, terminals and connecting parts. The shape of the busbars is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com