Real-time monitoring system of condensing state of concrete and real-time monitoring method

A real-time monitoring system and real-time monitoring technology, applied in the direction of material inspection products, etc., can solve the problems of floor concrete uplift, affecting construction accuracy, slump loss, etc., and achieve the effects of saving construction costs, accurate setting time, and simple settings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

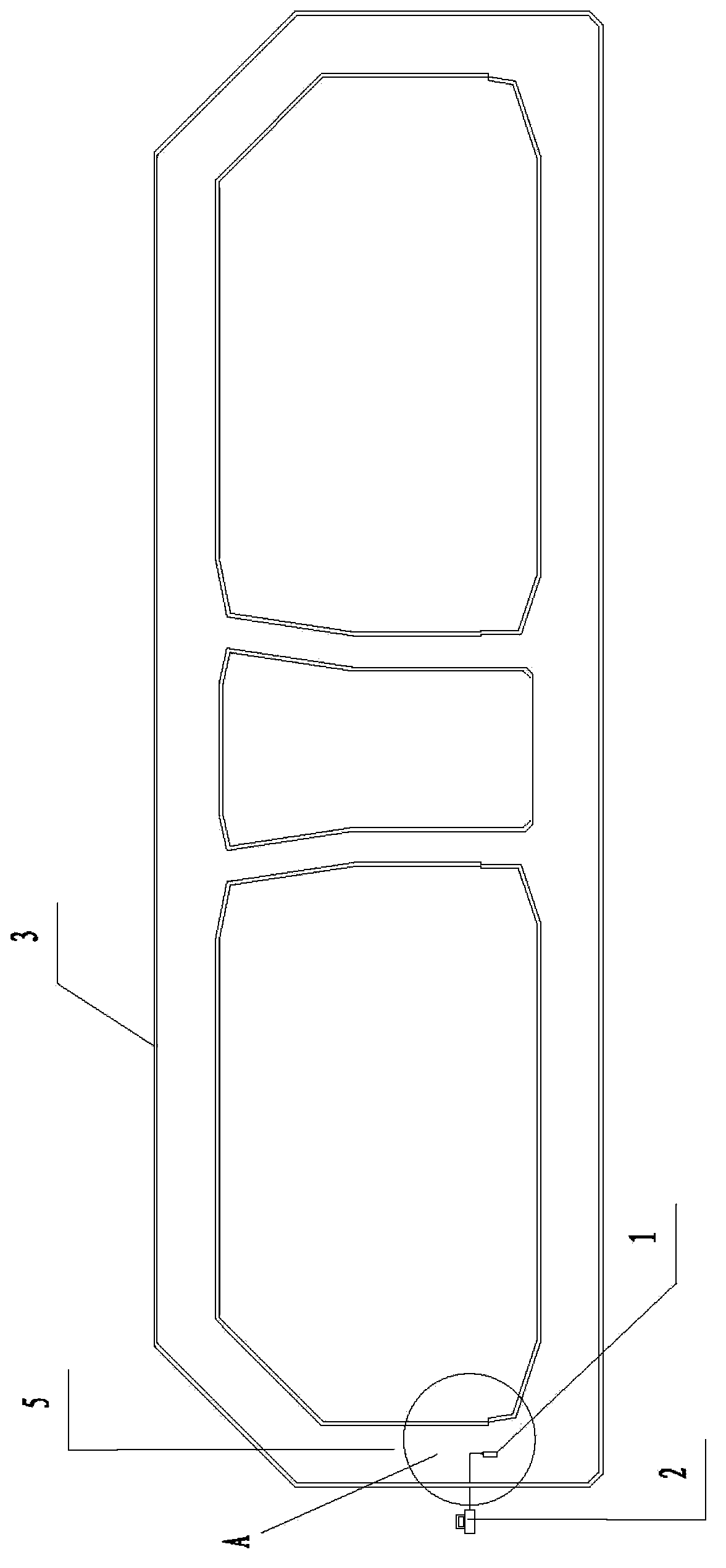

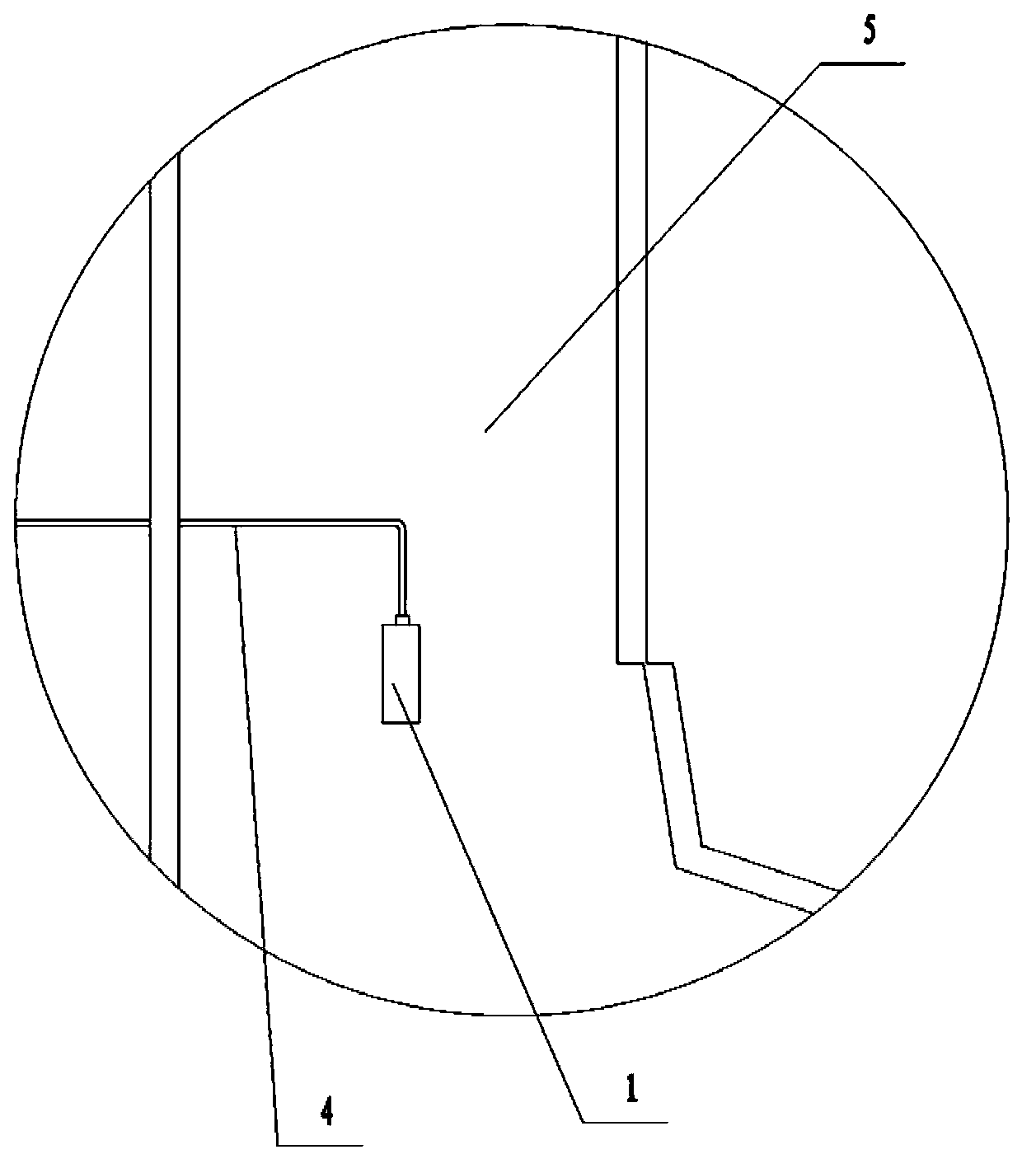

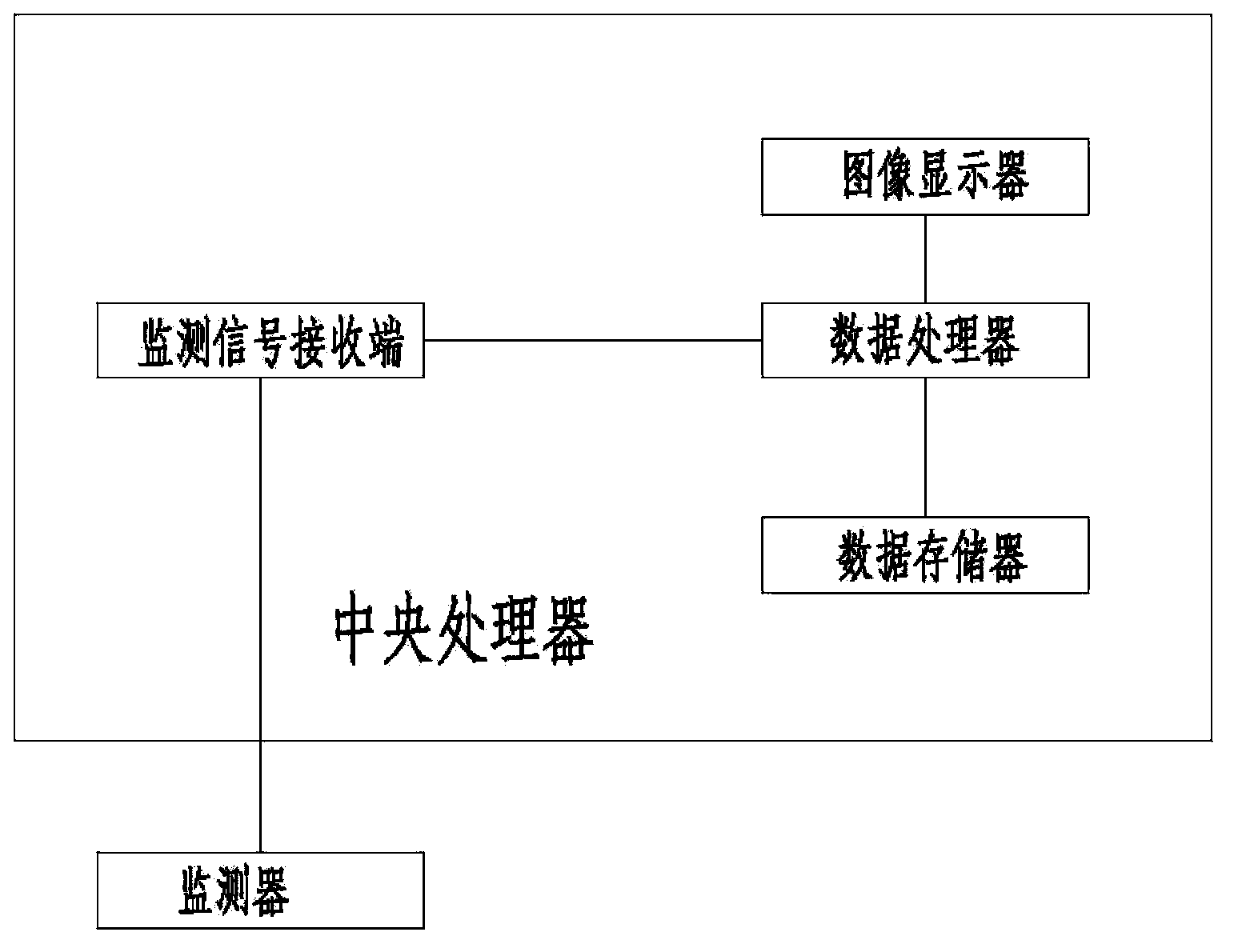

[0033] see figure 1 , figure 2 , image 3 As shown, the real-time monitoring system of the concrete setting state of the present invention, the real-time monitoring system includes a monitor 1 for real-time collection of concrete pressure values and a central processing unit 2 connected thereto; the monitor is arranged in the pouring formwork 3 , and connect with the central processing unit outside the pouring formwork through the signal transmission cable 4 . The monitor is arranged in the side wall 5 of the pouring formwork; the monitor is arranged along the vertical centerline of the side wall. The monitors are set corresponding to the pre-marked monitoring points on the side wall. The monitoring point refers to the place 285cm away from the bottom surface on the vertical center line of the side wall of the pouring formwork. The monitor described in this embodiment is an earth pressure gauge; the earth pressure gauge is a vibrating earth pressure gauge with a disk sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com