Natural gas hydrate core under-pressure transfer method and apparatus

A transfer method and transfer device technology, which are used in the preparation of test samples, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

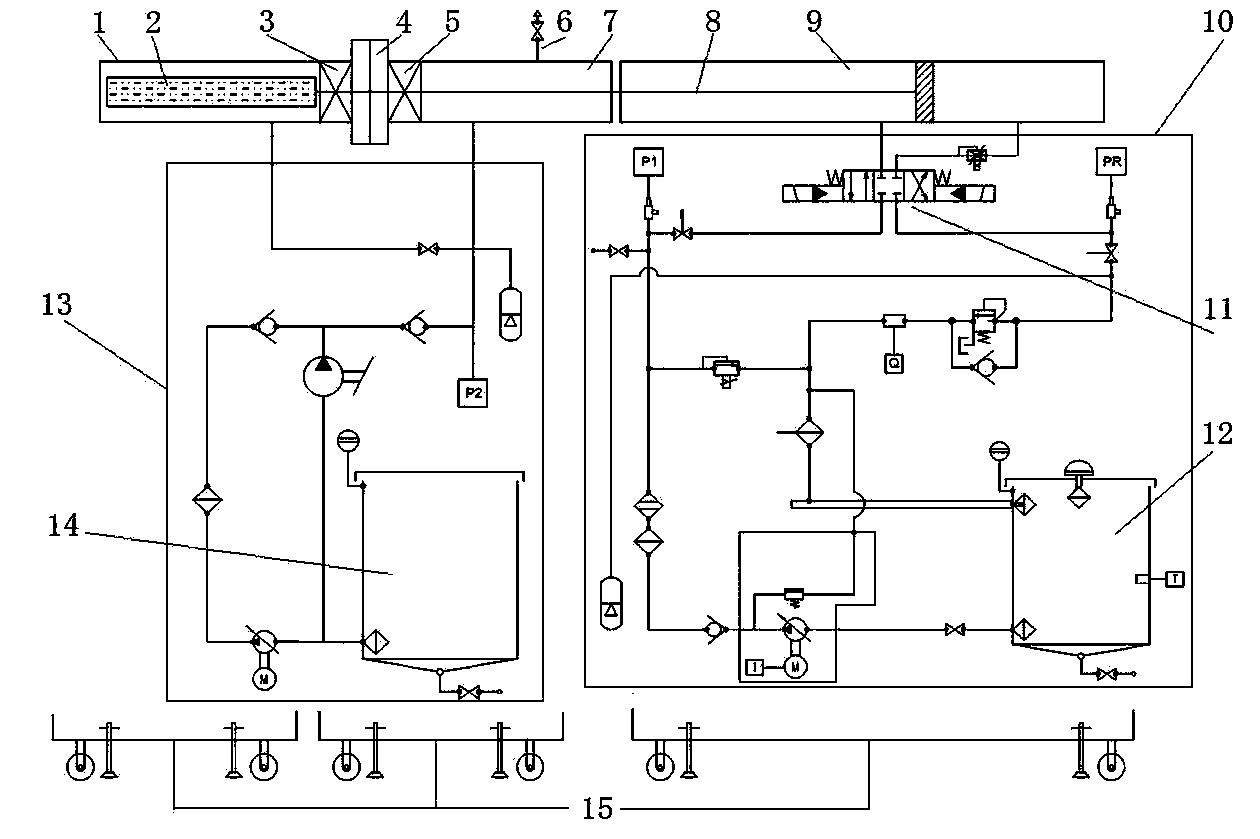

[0020] Embodiment 1 is a kind of optimized typical embodiment

[0021] First, a gas hydrate core transfer method under pressure.

[0022] The first step is to establish an end-to-end connection between the pressure-holding cylinder with the core tube and another transfer chamber with the same specifications as the pressure-holding cylinder; the second step is to send the core tube in the pressure-holding cylinder into the transfer chamber; The third step is to close the transfer bin and disconnect the connection with the pressure holding cylinder; in the above three steps, it is necessary to use an external pressure balance control system to always keep the pressure of the transfer bin the same as the initial state pressure of the pressure holding cylinder.

[0023] Wherein, the method for sending the core tube in the pressure-holding cylinder into the transfer bin is to use an external pull rod to pull the core tube in the pressure-holding tube into the transfer bin.

[0024...

Embodiment 2

[0028] Embodiment 2 is a simplified typical embodiment

[0029] First, a gas hydrate core transfer method under pressure.

[0030] The first step is to establish an end-to-end connection between the pressure-holding cylinder with the core tube and another transfer chamber with the same specifications as the pressure-holding cylinder; the second step is to send the core tube in the pressure-holding cylinder into the transfer chamber; The third step is to close the transfer bin and disconnect the connection with the pressure holding cylinder; in the above three steps, it is necessary to use an external pressure balance control system to always keep the pressure of the transfer bin the same as the initial state pressure of the pressure holding cylinder.

[0031] In the above-mentioned gas hydrate core transfer method under pressure, the method of sending the core tube in the pressure-holding cylinder into the transfer chamber is as follows: the docked pressure-holding cylinder an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com