Surface sinkage measuring method and measuring device thereof

A measurement equipment and measurement technology, applied in measurement devices, instruments, optical devices, etc., can solve the problems of scratching the surface of the object to be measured, the wear life of the contact probe, and the long time required to achieve accurate and stable The effect of measurement results, low damage rate, and fast detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

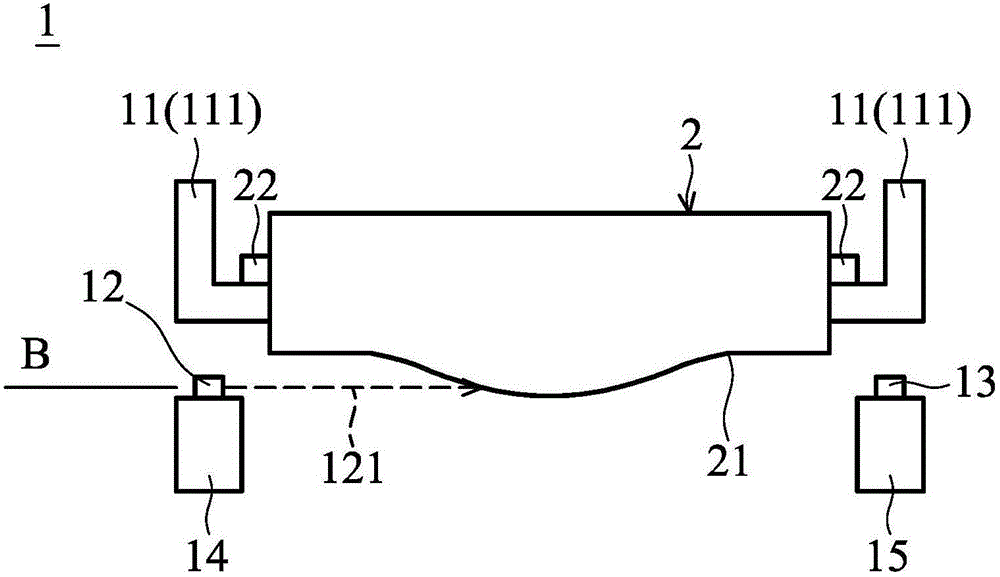

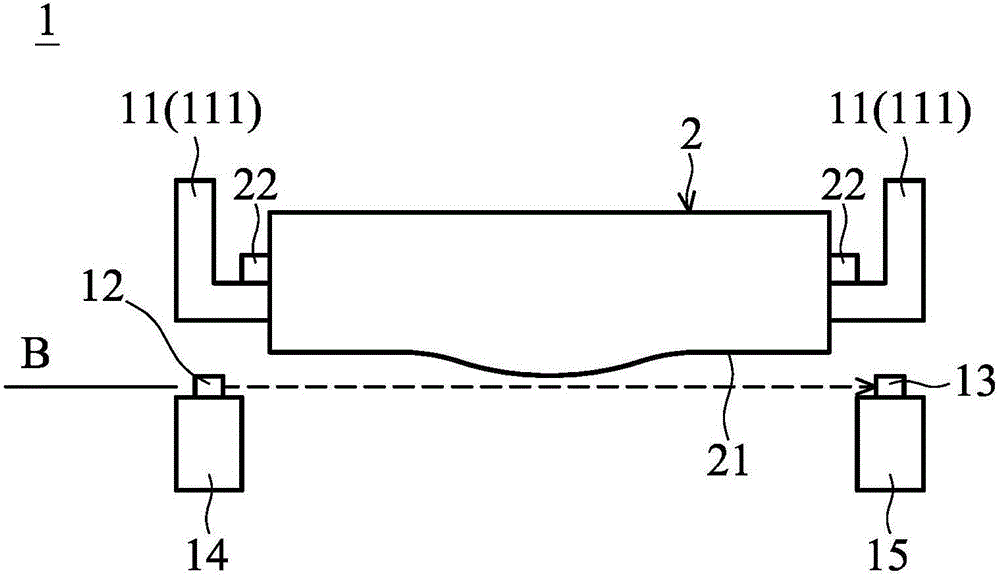

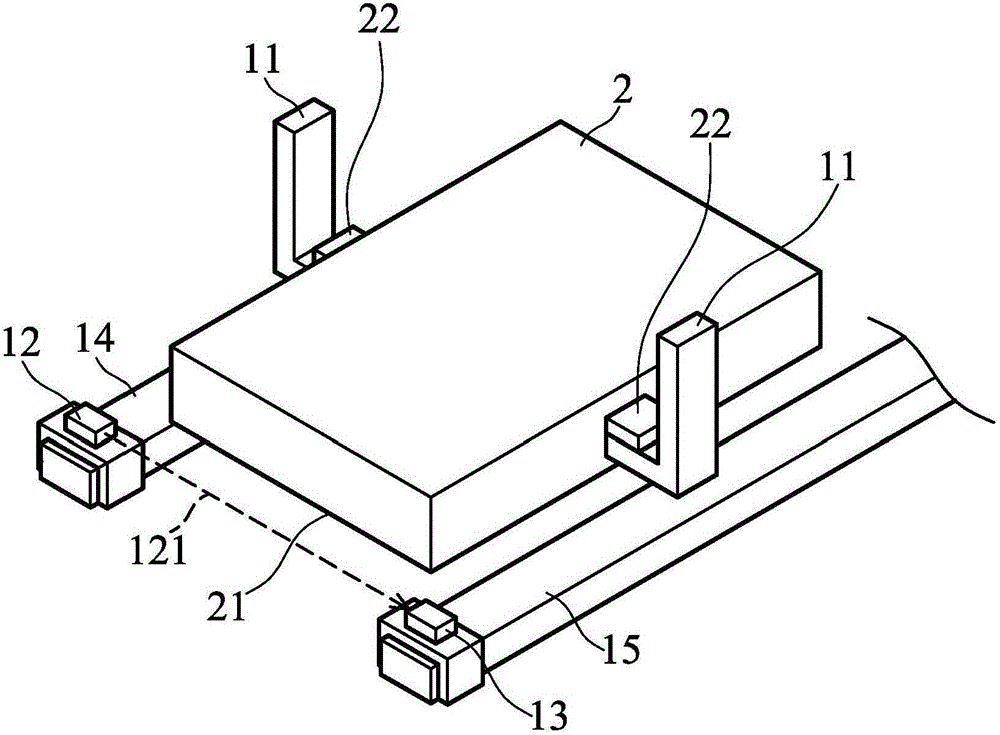

[0026] refer to figure 1 , figure 2 as well as image 3 , which shows the surface subsidence measurement device 1 according to the embodiment of the present invention, which is used to measure the subsidence of a casing surface 21 (lower surface) of a device 2 . The surface subsidence measurement device 1 includes a support frame 11 , a light source 12 , a receiver 13 and a control unit (not shown). The support frame 11 supports the device 2 . The light source 12 provides a light 121 , wherein the light source 12 is located on a reference plane B, and the light 121 travels along a horizontal direction. The receiver 13 receives the light 121 , wherein the receiver 13 is also located on the reference plane B. refer to figure 1 , when the subsidence of the casing surface 21 of the device 2 exceeds the allowable value, the casing surface 21 interferes with the reference plane B and prevents the receiver 13 from receiving the light 121 . refer to figure 2 , when the subsid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com