Open cut prefabricated underground structure

A prefabricated assembly and underground structure technology, which is applied to underwater structures, infrastructure engineering, water conservancy projects, etc., can solve the problems of long construction period, easy to cause fire, and many construction workers, and achieve its own durability and waterproof effect. , flexible and changeable structure, and the effect of improving the quality of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

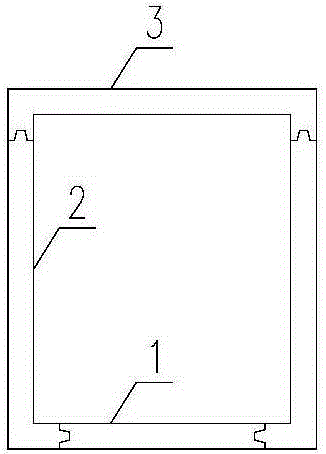

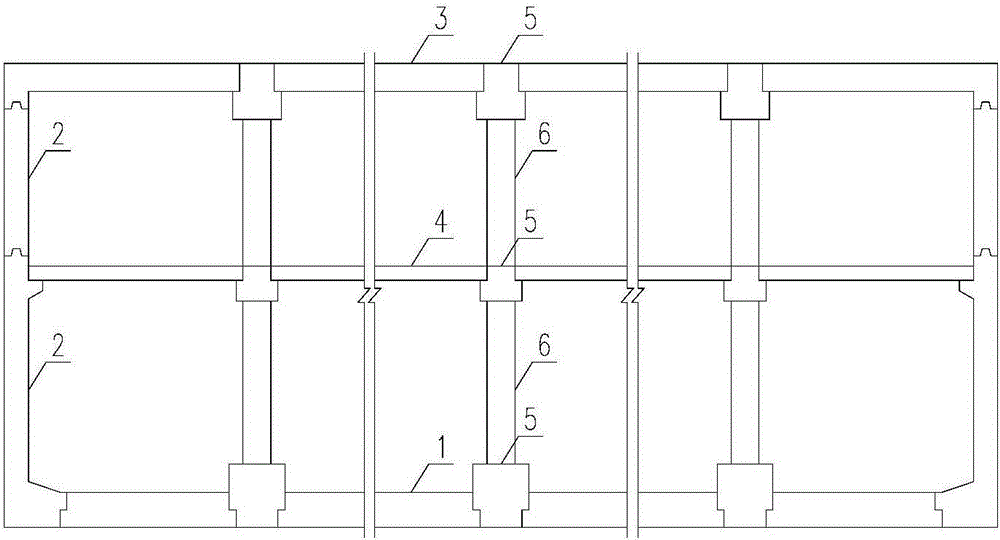

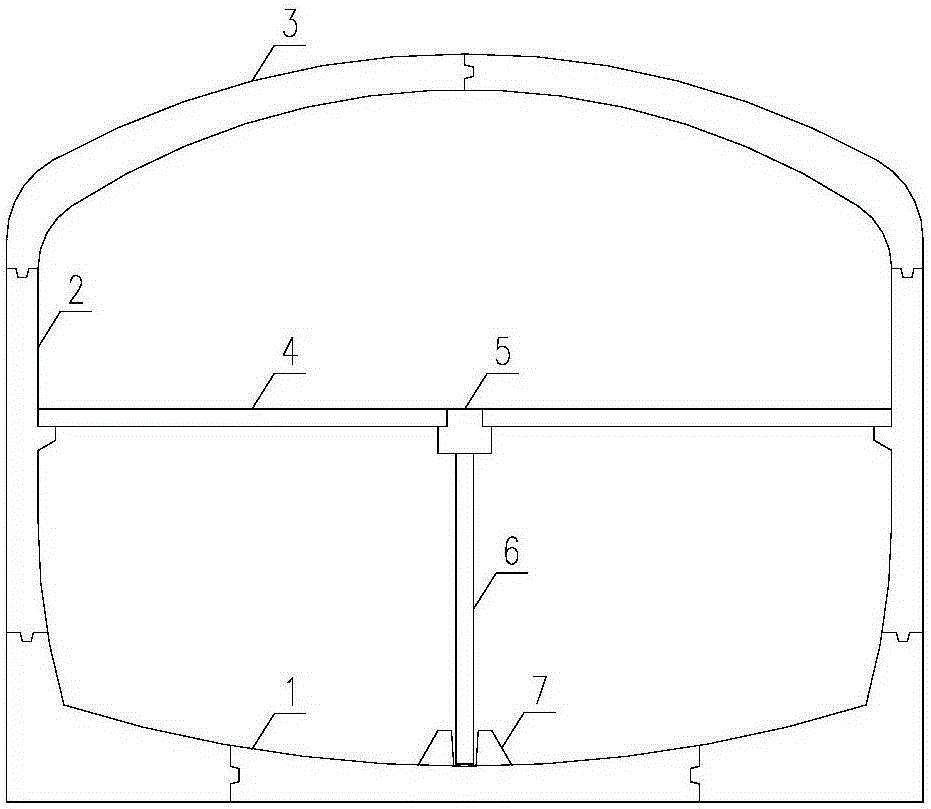

[0076] see Figure 1 to Figure 19 Shown: underground structure has multiple forms, below is example with typical subway station structure, in conjunction with accompanying drawing the specific embodiment of the present invention is described as follows:

[0077] (1) According to the section form and force characteristics of the main structure, determine the number of blocks and joint positions of the main frame structure;

[0078] (2) According to the force analysis of the main structure, determine the structural section form (solid type component 14, closed cavity type component 16, rib plate type component 17), size and joint connection form (concave-convex joint 10, stepped joint 11. Flat joints 12, cast-in-place joints 13) and connecting elements (circular connecting elements 20, longitudinal connecting elements 21), meeting the force requirements;

[0079] (3) Carry out streamlined prefabrication of component factories according to the design requirements, pre-embed hois...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com