Selenium-rich yeast and preparation method thereof

A technology of selenium-enriched yeast and inorganic selenium, applied in the field of food processing, can solve the problems of high environmental protection costs, pollution, serious problems, etc., and achieve the effect of balanced nutrition, easy digestion and absorption, and rich nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

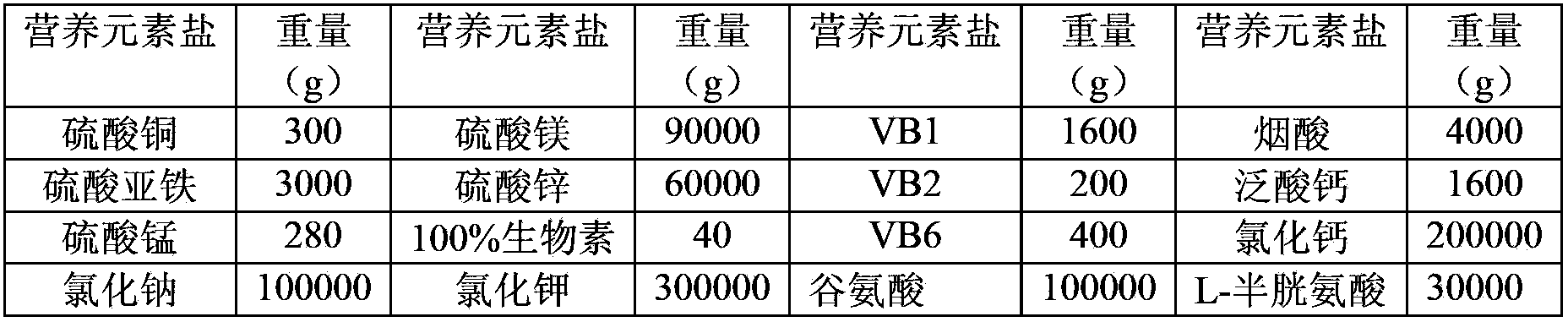

[0017] The invention provides a preparation method of selenium-enriched yeast, which includes the steps of gradually expanding and culturing yeast strains, fermenting and culturing, collecting yeast cells and drying and crushing; wherein, in the fermenting and culturing step, hydrolyzed sugar is used as a carbon Selenium yeast culture, selenium-enriched yeast culture includes amino acid, selenium salt and nutrient element salt.

[0018] By using hydrolyzed sugar as a carbon source in the fermentation process, and adding selenium-enriched yeast cultures including amino acids, selenium salts and nutrient element salts during the fermentation process, the selenium content in the prepared selenium-enriched yeast is as high as 3000ppm. Balanced and rich, easy to digest and absorb. The preparation method has simple process, low raw material price, and can be produced on a large scale. In addition, when preparing selenium-enriched yeast with high selenium content, the pressure of env...

Embodiment 1

[0033] The baker's yeast strain (commercially available product) stored in liquid nitrogen was activated on YPD medium, and after 48 hours of constant temperature cultivation at 30°C, it was stored in a refrigerator at 4°C for later use.

[0034] Gradually expand the obtained strains into 60-ton seed tanks with Erlenmeyer flasks and Karl Fischer flasks. The culture medium is put into a 300-ton fermenter, and after the bleaching powder is sterilized, the prepared seeds are put into the fermenter by the differential pressure method for fermentation and cultivation. Calculating that the amount of inoculated yeast is 6500L, it is 27% hydrolyzed sugar, 17% ammonia water and 10% sodium selenite solution added to the culture medium, wherein the hydrolyzed sugar is Add 15ml / hour per liter of fermentation broth, then the total amount added is 79 cubic meters; ammonia water is added at 0.25ml / hour per liter of fermentation broth, then the total amount added is 2.2 cubic meters; Liquid ...

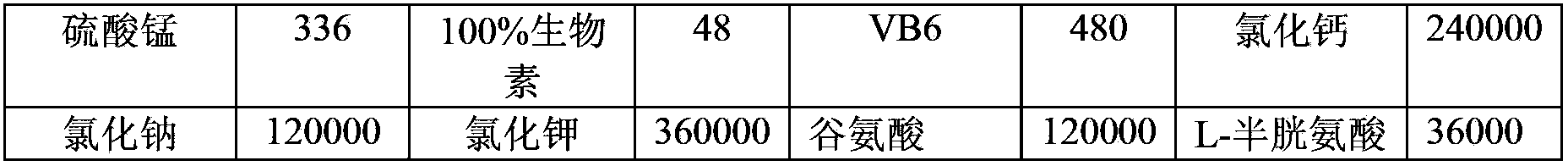

Embodiment 2

[0039] The baker's yeast strain preserved in liquid nitrogen was activated on YPD medium, and after 48 hours of constant temperature cultivation at 30°C, it was stored in a refrigerator at 4°C for later use.

[0040] Gradually expand the obtained strains into 60-ton seed tanks with Erlenmeyer flasks and Karl Fischer flasks. The culture medium is put into a 300-ton fermenter, and after the bleaching powder is sterilized, the prepared seeds are put into the fermenter by the differential pressure method for fermentation and cultivation. Calculated on the basis that the amount of inoculated yeast is 7500L, add hydrolyzed sugar with a mass ratio concentration of 27% and ammonia water with a mass ratio concentration of 17% to the medium, wherein the hydrolyzed sugar is added at 42ml / hour per liter of fermentation broth, then add The total amount is 79 cubic meters; ammonia water is added at a rate of 0.25ml / hour per liter of fermentation medium, and the total amount added is 2.6 cub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com