Scanning Weighing Labeling Machine and How to Use It

A labeling machine and weighing mechanism technology, applied in packaging machines, electromagnetic radiation induction, packaging automatic control, etc., can solve problems such as inability to effectively achieve mass production, consume manpower, and reduce operating efficiency, so as to save packaging processes and operations Time, reduce labor costs, and promote the effect of industrial upgrading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

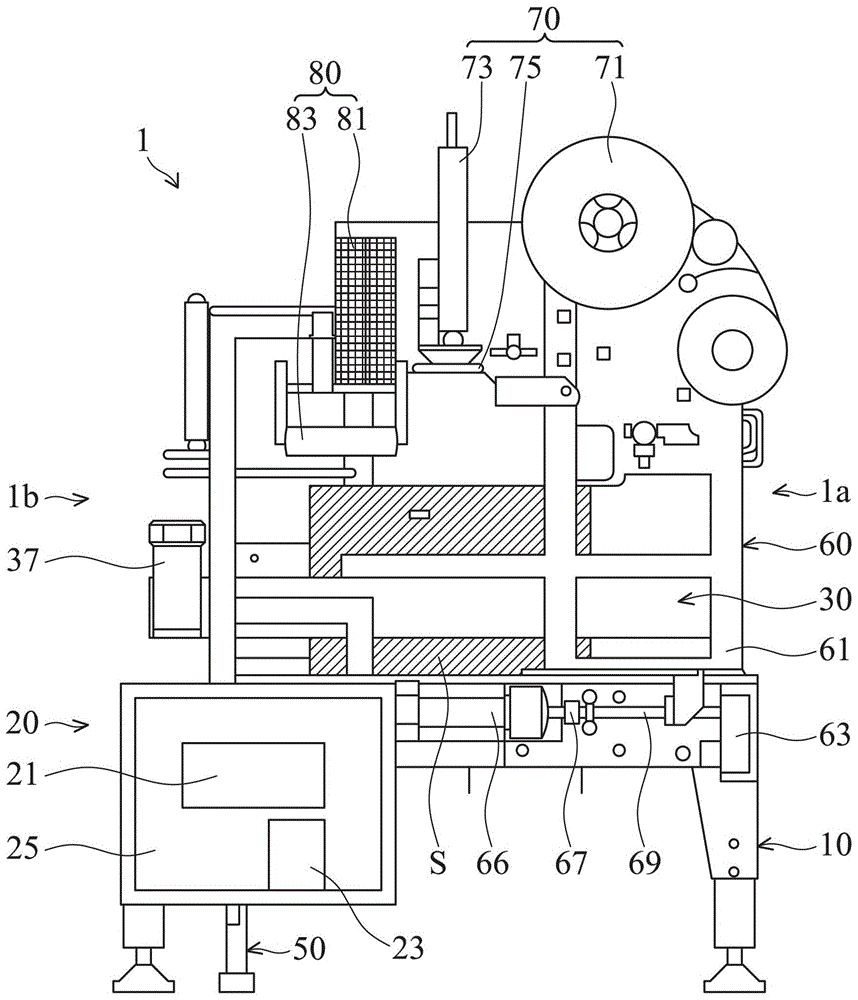

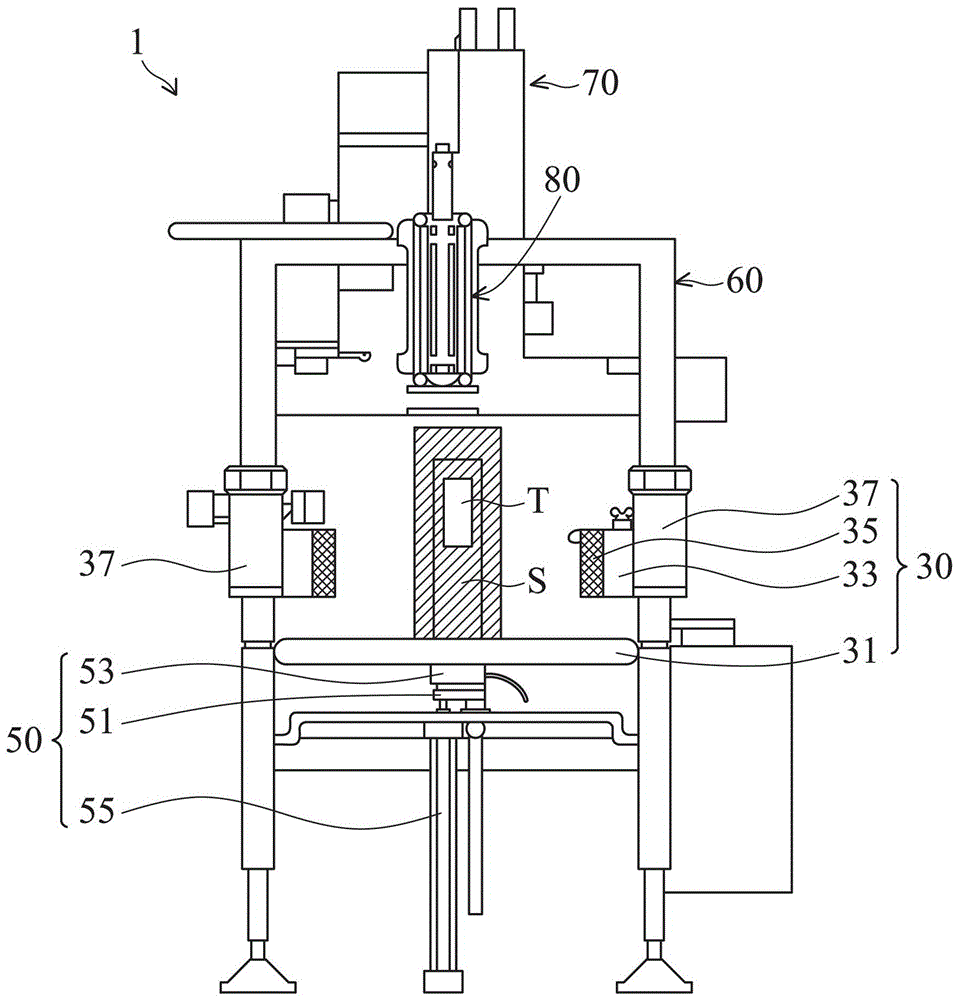

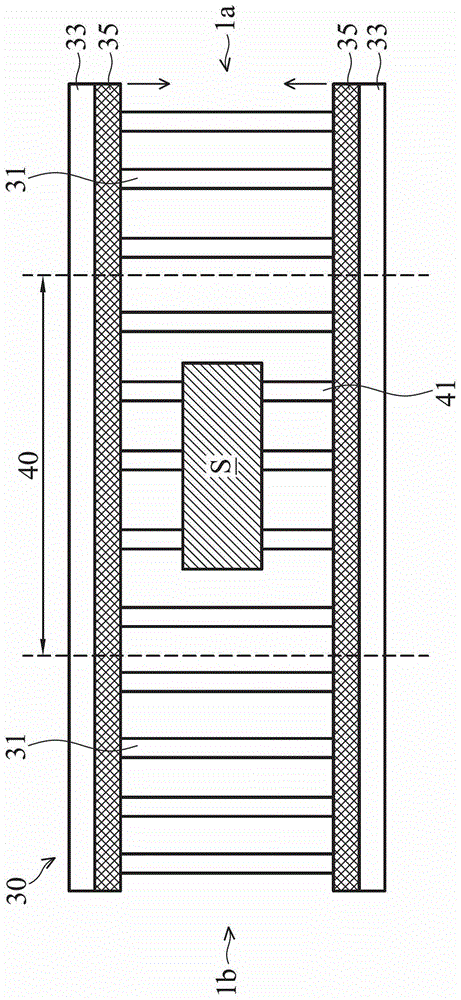

[0034] In order to make the purpose, features, and advantages of the present invention more comprehensible, preferred embodiments are specifically cited below, together with the accompanying drawings Figure 1 to Figure 4 , to explain in detail. The description of the present invention provides different examples to illustrate the technical features of different implementations of the present invention. Wherein, the configuration of each component in the embodiment is for illustration, not for limiting the present invention. In addition, part of the reference numerals in the embodiments are repeated for the purpose of simplifying the description, and do not imply the correlation between different embodiments.

[0035] Please also refer to figure 1 , figure 2 . The scanning, weighing and labeling machine 1 of an embodiment of the present invention comprises: a machine platform 10, wherein the machine platform 10 is provided with: a computer system 20, a conveying device 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com