Automation production assembling method of electric power instrument housing based on JIT and one-piece flow idea

A technology of power meter and assembly method, which is applied in the field of automatic production and assembly of power meter shells, can solve problems such as difficulty in improving production efficiency, high labor intensity of workers, and many production safety accidents, so as to improve quality, shorten production time, and reduce labor costs. intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

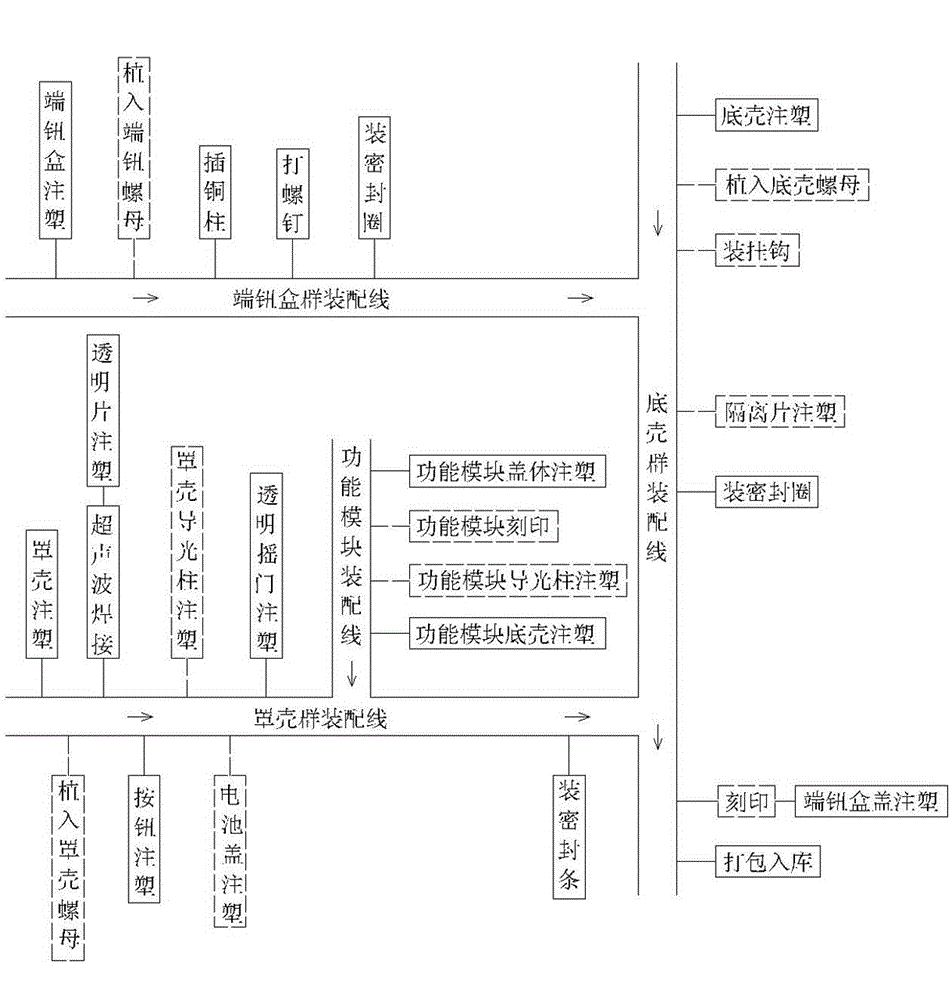

[0030] refer to figure 1 , an automatic production and assembly method for electric meter housings based on the concept of JIT and one-piece flow, comprising the following steps:

[0031] (1) In the end button box injection molding area, the end button box is fully automatic injection molded by the end button box injection molding machine. The end button box injection molding machine is a special automatic injection molding machine for injection molding the end button box. The ordinary injection molding machine is equipped with a special injection mold, and the shape of the cavity of the injection mold matches the shape of the end button box, and then the formed end button box is placed on the end button box group assembly line and passed through the end button box The group assembly line transports the terminal box forward to the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com