Support positioning device for outside micrometer measurement

A support positioning and micrometer technology, applied in the direction of micrometers, auxiliary devices, measuring/indicating equipment, etc., can solve problems such as easy fatigue of arms and wrists, decreased measurement accuracy, laborious measurement errors, etc., and achieve a reasonable and accurate overall structure design The effect of high precision and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

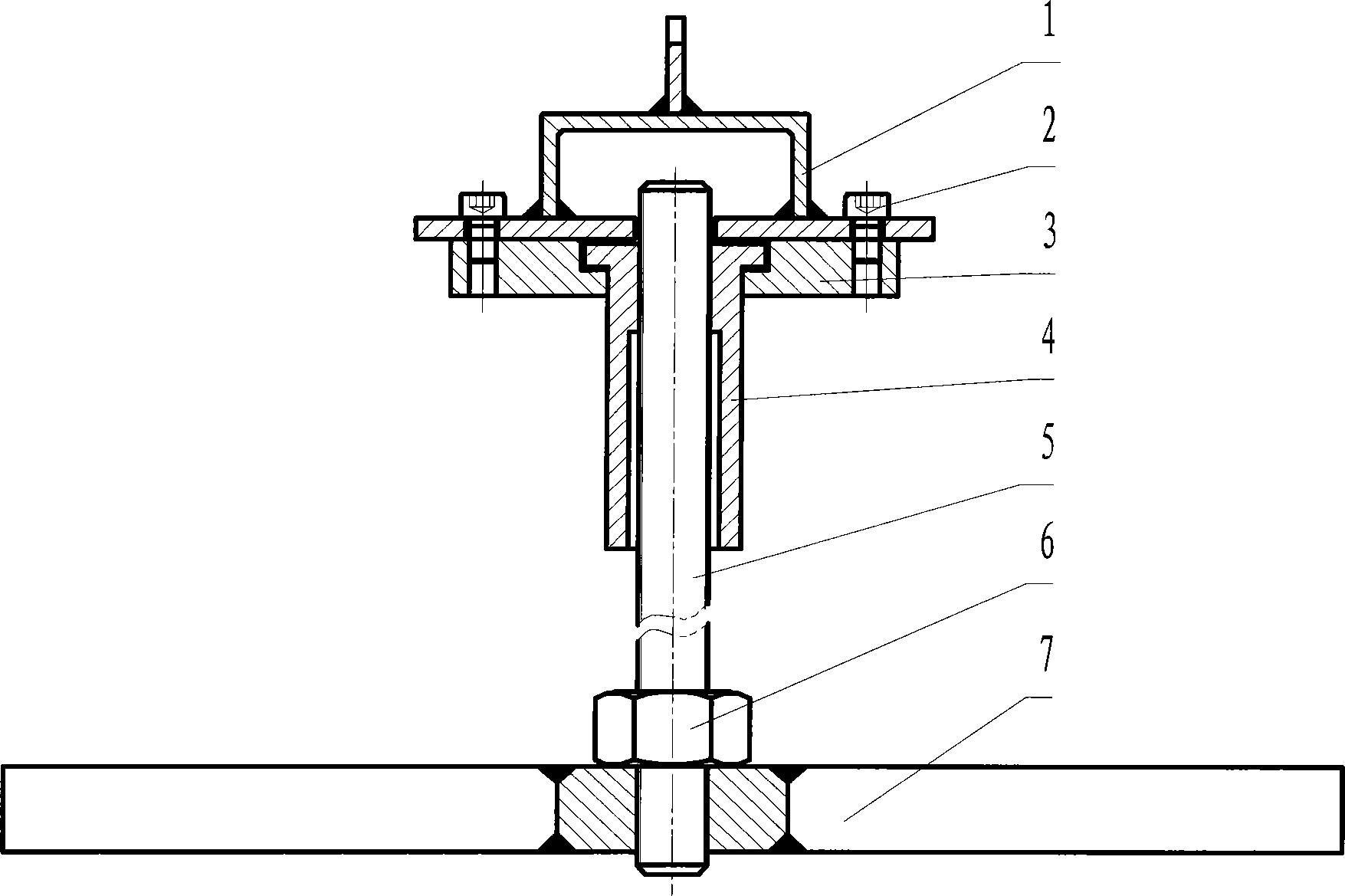

[0013] Among the figure: 1, V-shaped support plate, 2, countersunk head screw, 3, connection plate, 4, lifting sleeve, 5, long screw rod, 6, lock nut, 7, support base.

[0014] From Figure 1-5 It can be seen from the figure that the support and positioning device for outer diameter micrometer measurement is composed of: V-shaped support plate 1, countersunk head screw 2, connecting plate 3, lifting sleeve 4, long screw rod 5, lock nut 6, and bracket base 7.

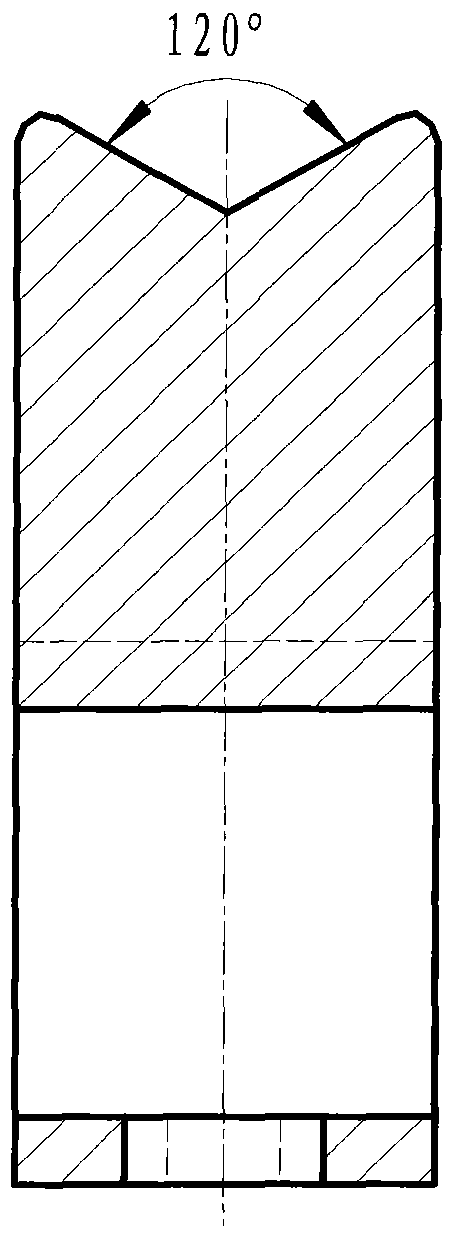

[0015] From Figure 2~4 It can be seen from the figure that the top of the V-shaped support plate 1 has a V-shaped groove matching the outer micrometer frame, and the included angle is 120°.

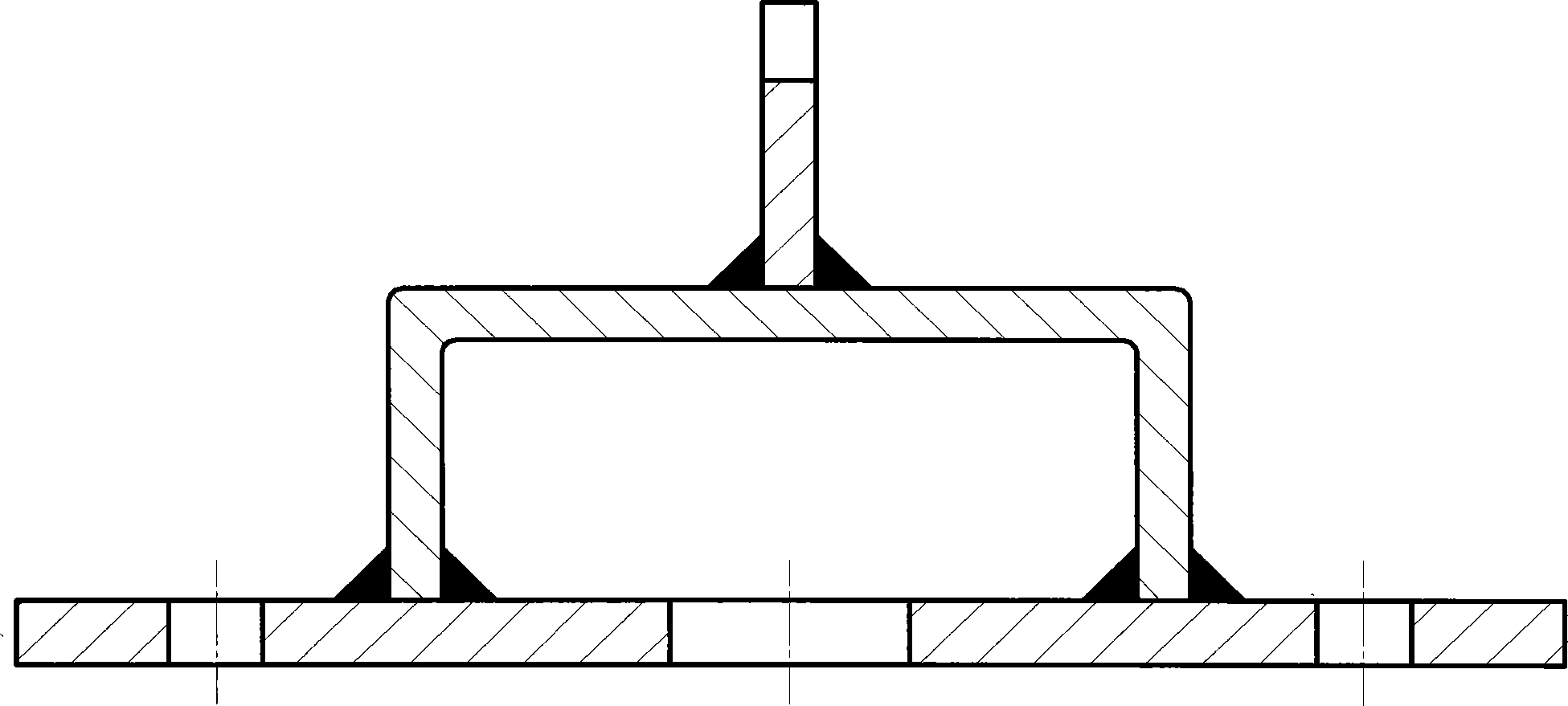

[0016] From Figure 4 It can be seen from the figure that the middle hole of the connecting disc 3 and the outer circle of the lifting sleeve 4 are hole shaft clearance fits, and there is a gap of 0.5mm between the top surface of the lifting sleeve 4 and the bottom surface of the V-shaped support plate 1.

[0017] When measuring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com