Undirected fixed-discharging type blanking die

A technology for fixing unloading and blanking molds, applied in the field of molds, can solve the problems of difficulty in controlling the matching precision of the concave mold and the punching mold, high requirements for operation technology, and high rejection rate of blanking parts. The effect of low technical level requirements and reduced operation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

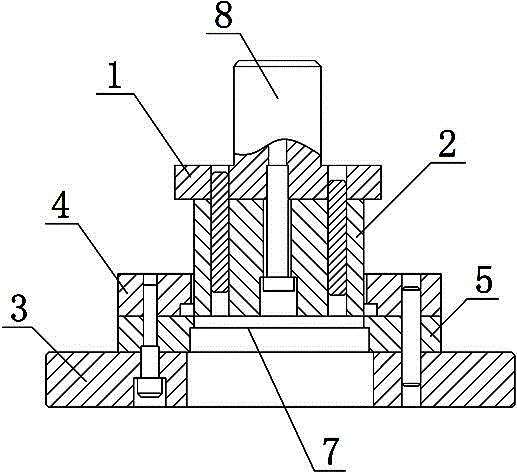

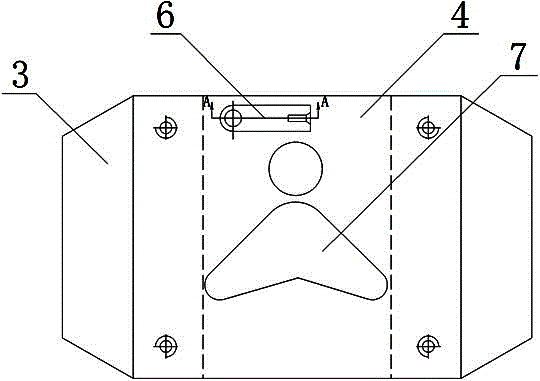

[0018] Such as figure 1 As shown, the non-guided fixed discharge blanking mold includes an upper mold base 1, a punch 2, a lower mold base 3 and a die 5, and a mold handle 8 is connected to the upper center of the upper mold base 1, and the mold handle 8 is connected to the The external press is connected, the punch 2 is fixed under the upper die base 1 by screws, and positioned by at least two positioning pins; the upper die base 3 is fixedly installed with a die 5 and a stripping plate 4 from bottom to top, The die 5 is provided with a blanking hole 7 matching the punch 2 .

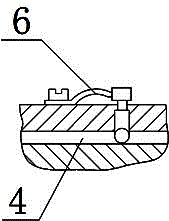

[0019] The rear side of the said die 4 is also provided with a stopper pin 6 .

[0020] The said stop pin 6 is a belt-back type stop pin.

[0021] The working process of the present invention is as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com