Glass bottle head breaking and separating system

A separation system and glass breaking technology, applied in solid separation, grading, sieving and other directions, can solve the problems of dust flying on the production site, damage to workers' health, water spraying of glass raw materials, etc., to protect the environment and employee health, and improve workers. Work environment, manpower saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

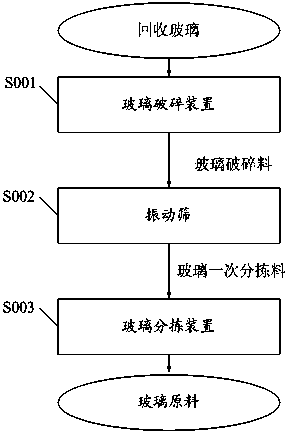

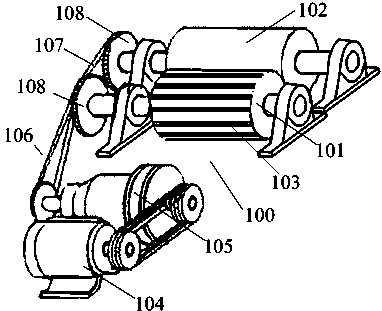

[0032] Such as Figure 1-Figure 7 As shown, the first embodiment of the present invention provides a glass bottle head breaking and separating system, including a glass breaking device 100, a vibrating screen 200 and a glass sorting device 300,

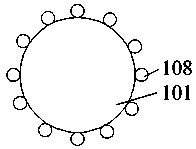

[0033] The glass breaking device 100 includes a frame and a first roller 101 and a second roller 102 arranged on the frame, the first roller 101 and the second roller 102 rotate in opposite directions, and the first roller 101 and the second roller There is a predetermined gap between the two rollers 102, and the glass to be broken is crushed by the combined extrusion of the first roller 101 and the second roller 102;

[0034] The vibrating screen 200 comprises a box body, an exciter 202 arranged at the horizontal center...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com