Water-cooled heat dissipation device

A water-cooled radiator and heat-dissipating column technology, applied in the field of heat dissipation, can solve the problems of weakening, easy aging of the sealing ring, and affecting the service life of the water-cooled radiator.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Attached below Figures 1 to 6 The present invention is described in further detail.

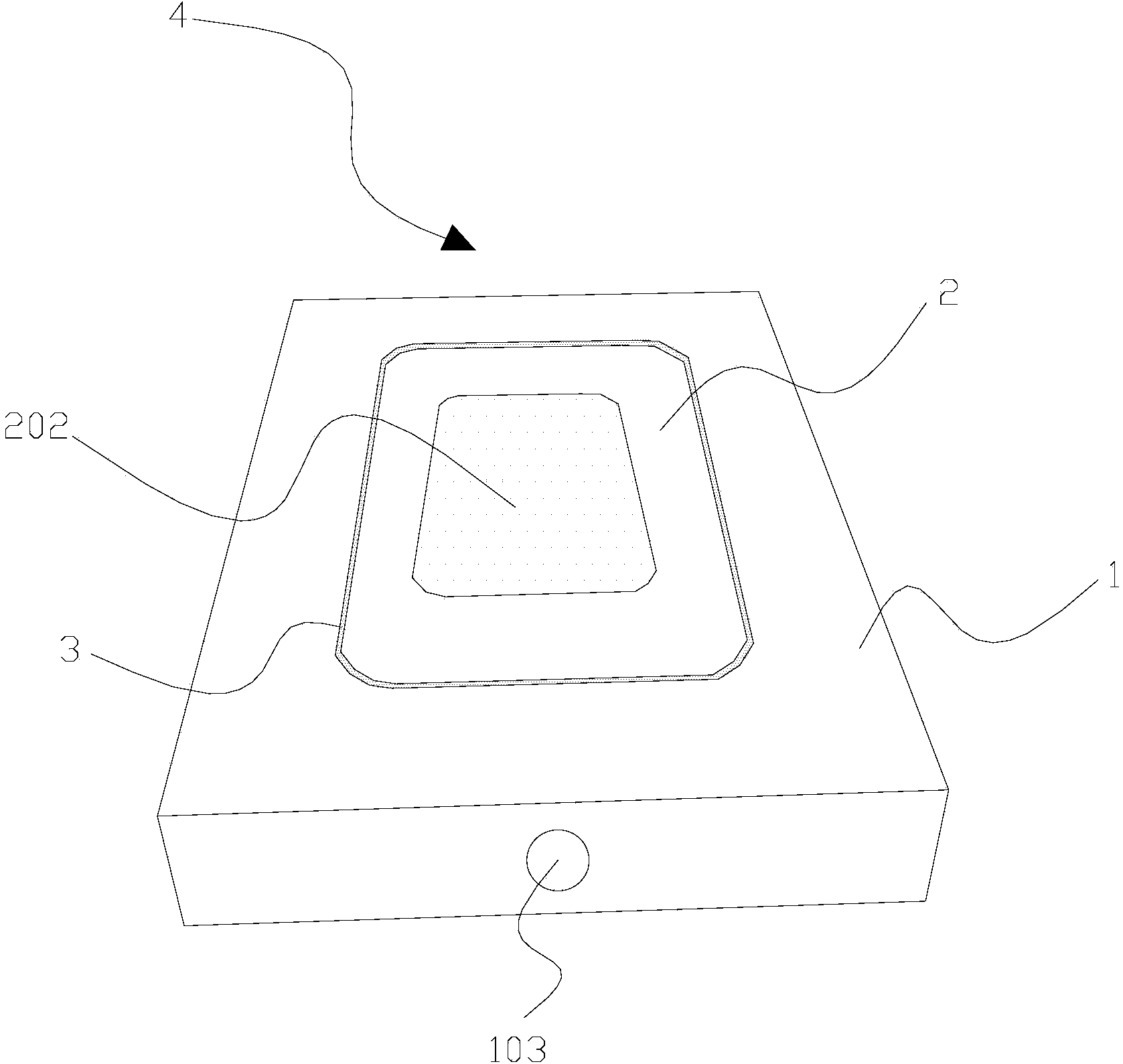

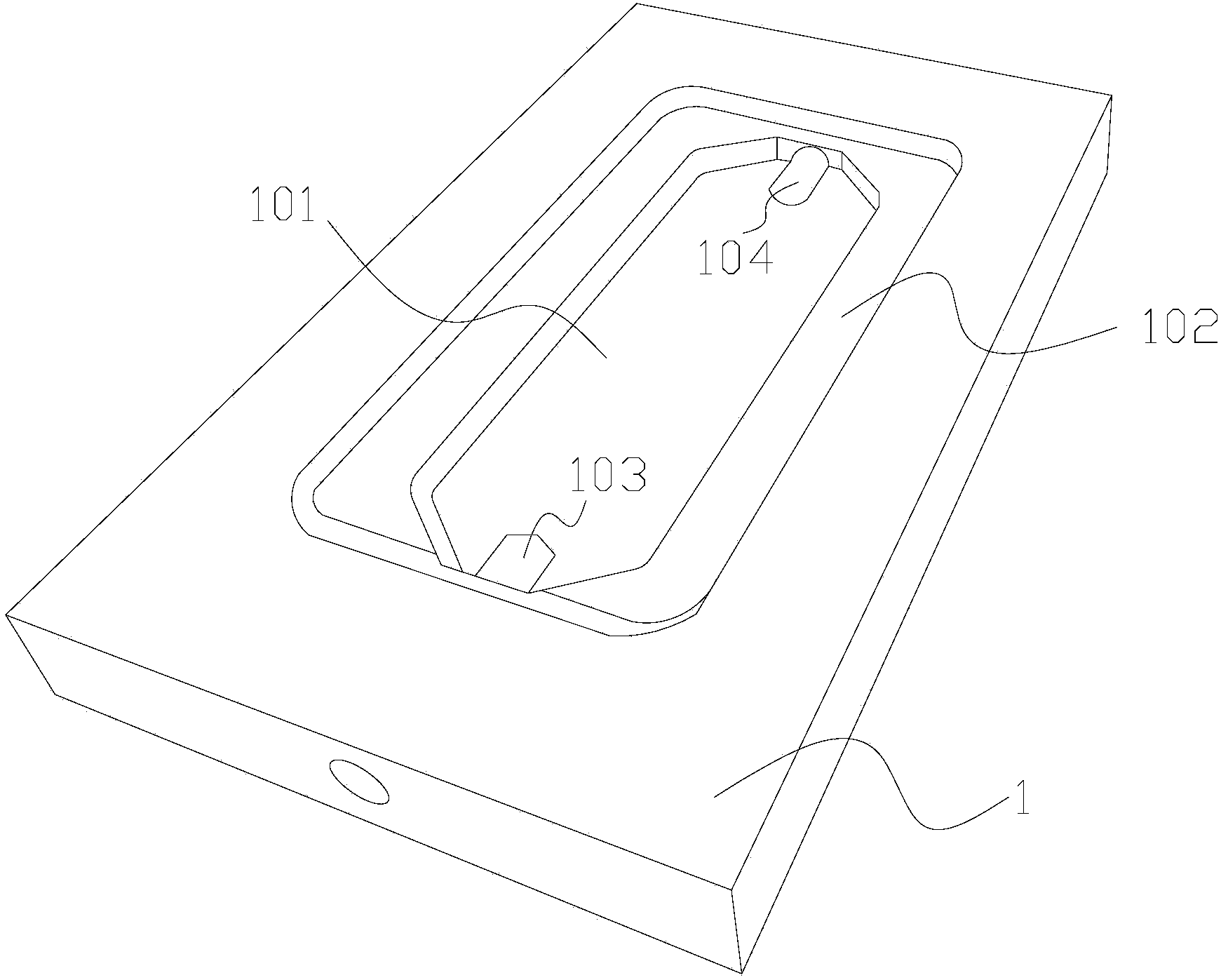

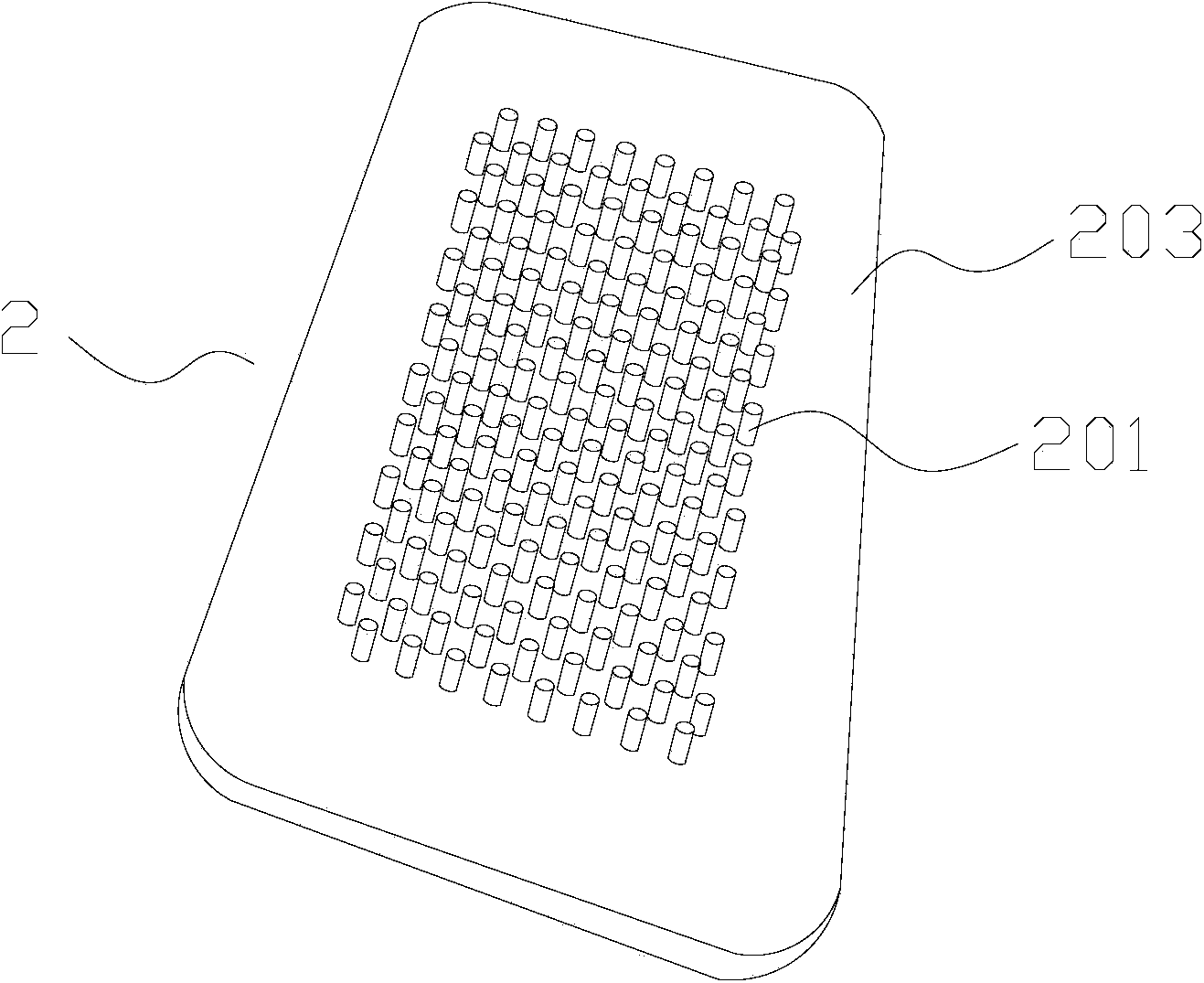

[0020] refer to Figure 1 to Figure 4 , provides a water-cooled radiator, including a heat dissipation body 4 and a plurality of heat dissipation columns 201 . The heat dissipation main body 4 includes a base 1 and a cover plate 2 that can be interlocked with the base 1. The base 1 is provided with a water inlet 103, a water outlet 104, and an accommodating chamber 101 that communicates with the water inlet 103 and the water outlet 104. The water inlet 103 and the water outlet 104 are respectively located at two ends of the accommodating cavity 101 . The side surface 203 of the cover plate 2 is evenly distributed with heat dissipation columns 201 , and the plurality of heat dissipation columns 201 can be cylinders or cuboids, or can also be frustum of cones for the convenience of processing. In this embodiment, they are cylinders. The plurality of heat dissipation columns 201 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com