A stator permanent magnet type dual rotor motor structure for hybrid electric vehicles

A technology for hybrid electric vehicles and dual-rotor motors, which is applied in electrical components, electromechanical devices, etc., can solve the problems of unguaranteed reliability, large amount of permanent magnets, low utilization rate, etc. The effect of large, high efficiency and power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

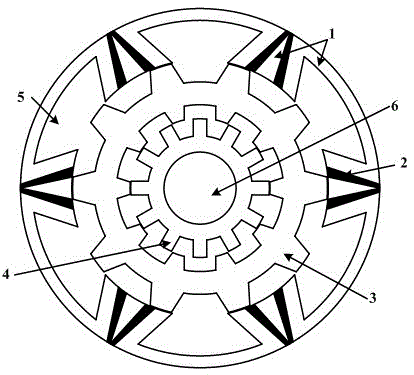

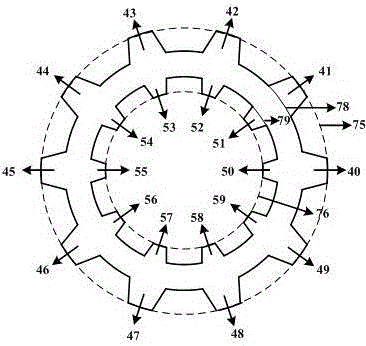

[0024] The stator permanent magnet type dual-rotor motor structure proposed by the present invention is as follows: figure 1 As shown, it includes coaxial outer stator core unit 1 , outer stator permanent magnet 2 , outer rotor 3 , inner rotor core unit 4 , rotating shaft 6 and so on. The inner rotor core unit 4 is fixedly sleeved on the rotating shaft 6 , the outer rotor 3 is sleeved with a gap outside the inner rotor core unit 4 , and the outer stator core unit 1 is sleeved with a gap outside the outer rotor 3 .

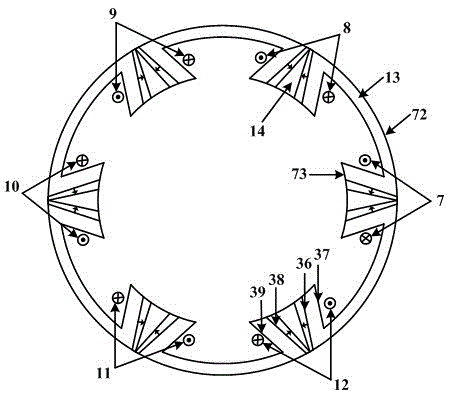

[0025] Such as Figure 1-2 As shown, the outer stator core unit 1 is composed of 6 grooved core units 13 of the same structure and 6 isosceles triangular core units 14 of the same structure. There is an outer stator groove 5 in the middle of each groove core unit 13, and the openings of the 6 outer stator grooves 5 are all facing the axis line, and the groove bottom size of the outer stator groove 5 is larger than the notch size, and the notch is smaller. Small a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com