Barrel-shaped mechanism with self-power-generation function

A technology of flashlights and DC generators, applied in the direction of engines, machines/engines, electrical components, etc., can solve the problems of insufficient power supply, poor light transmission, etc., and achieve the effects of easy disassembly, long life and good sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

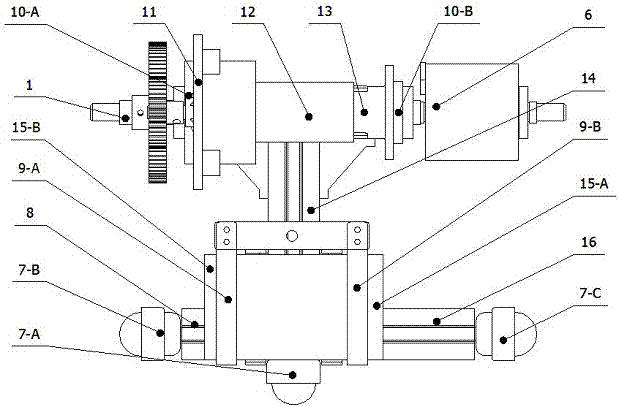

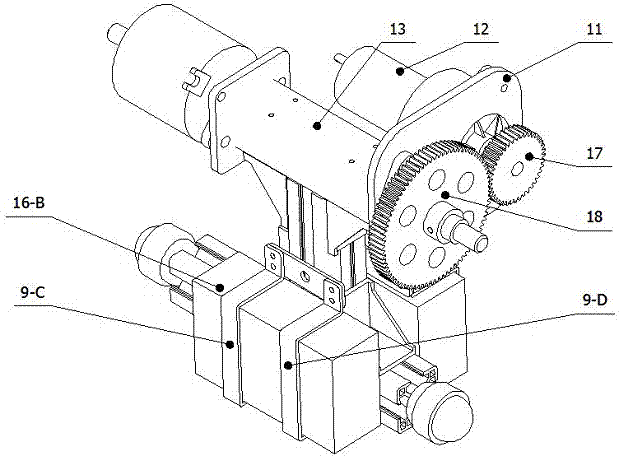

[0024] refer to Figure 1 ~ Figure 3 , the self-generating cylindrical mechanism, including a cylindrical shell (3), a left cover (2), a right cover (5), a shaft (1), a pendulum type autonomous generating mechanism (4) and a through-hole conductive slip ring (6). There are carabiner holes (20) on the flange side of the cylindrical housing (3), and the cylindrical mechanism can be installed in the internal hollow robot through carabiners (not shown in the figure). The pendulous self-generating mechanism (4) is coaxially installed in the cylindrical housing (3), and the pendulum-type self-generating mechanism (4) can rotate around the shaft (1), and through the large and small spur gears (18, 17) are meshed and driven to drive the rotor of the DC generator (12) to rotate relative to its stator to realize autonomous power supply. The through-hole conductive slip ring (6) can complete the connection between internal and external signal lines, ensuring good sealing of the ...

Embodiment 2

[0026] This embodiment is basically the same as Embodiment 1, and the special features are as follows:

[0027] The pendulous self-generating mechanism (4) consists of a cross bar (13), a swing bar (14), a left bar (8), a right bar (16), a connecting plate (11), A large spur gear (18), a small spur gear (17), a DC generator (12), two bearing housings (10-A, 10-B), two low-temperature batteries (15-A, 15-B ) and four battery clamps (9-A, 9-B, 9-C, 9-D); one side of the connecting plate (11) is fixed on the cross bar (13) by countersunk screws, Fix the DC generator (12) stator on the other side with screws; the bearing seats (10-B, 10-A) are respectively fixed on the cross bar (13) and the connecting plate (11); the large The spur gear (18) is fixed on the shaft (1), and the small spur gear (17) is connected with the rotor of the DC generator (12); The left rod (8) and the right rod (16) are fixedly connected with the swing rod (14) by corner pieces; the battery clips (9-A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com