Compact-type inductance-integrated electrode and processing method thereof

A compact, inductive technology, applied in the direction of transformer/inductor coil/winding/connection, contact manufacturing, contact components, etc., which can solve the problems of bulk insulators in switching loops, undesired technical manufacturing costs, and increased manufacturing costs. , to ensure the electric field dielectric strength, improve breakdown stability, and improve the effect of dielectric strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

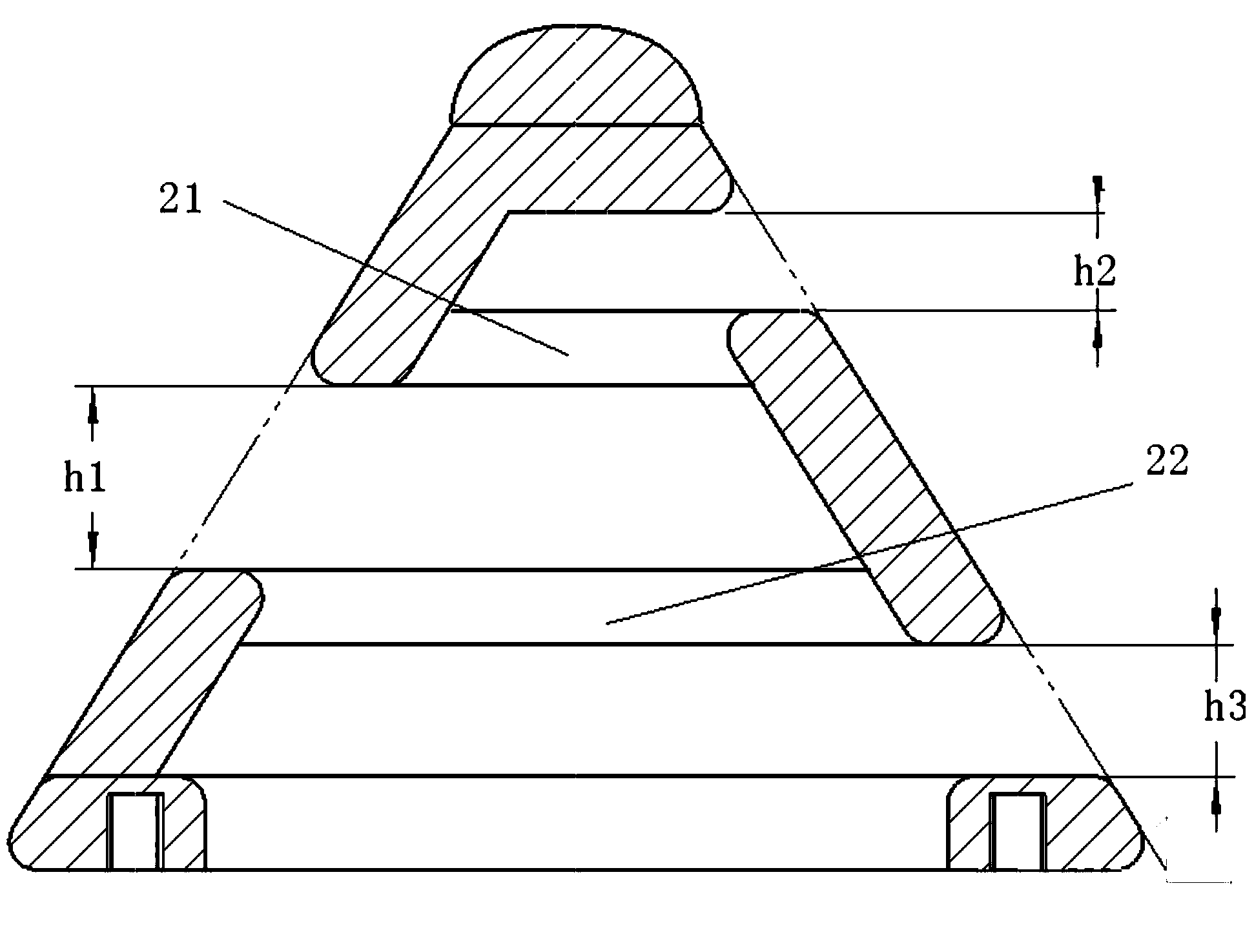

[0040] like figure 1 As shown, a compact inductive integrated electrode of the present invention includes an electrode head 1, an electrode chassis 4, and an inductance unit arranged between the electrode head and the electrode chassis; the electrode chassis is a circular structure; the inductance unit includes a semicircular inductance 2. The semi-circular inductance is parallel to the electrode chassis, one end of which is connected to the electrode head through the inductance support section, and the other end is connected to the electrode chassis; 2. The height of the inductance support section meets the insulation performance requirements of the inductance, and can be placed in insulating gas or liquid. switch. The electrodes are machined from high conductivity, non-ferromagnetic brass material. The surface of the tip of the electrode transitions smoothly, forming a slightly uneven electric field with an electric field unevenness coefficient less than 2.

[0041] The ov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com