Material cutting power and energy consumption obtaining and energy-saving control method in variable cutting rate process

A cutting power and energy-saving control technology, applied in the direction of electrical program control, digital control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will now be explained in detail in conjunction with the embodiments and the accompanying drawings.

[0053] The control method of material cutting power and energy consumption in the variable cutting rate process of the embodiment of the present invention comprises the following steps:

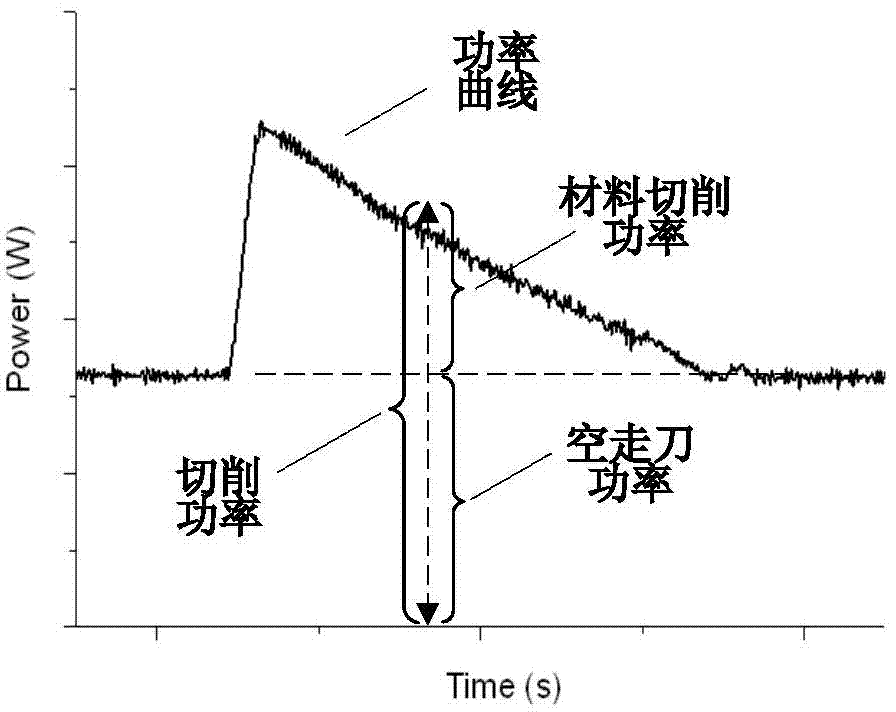

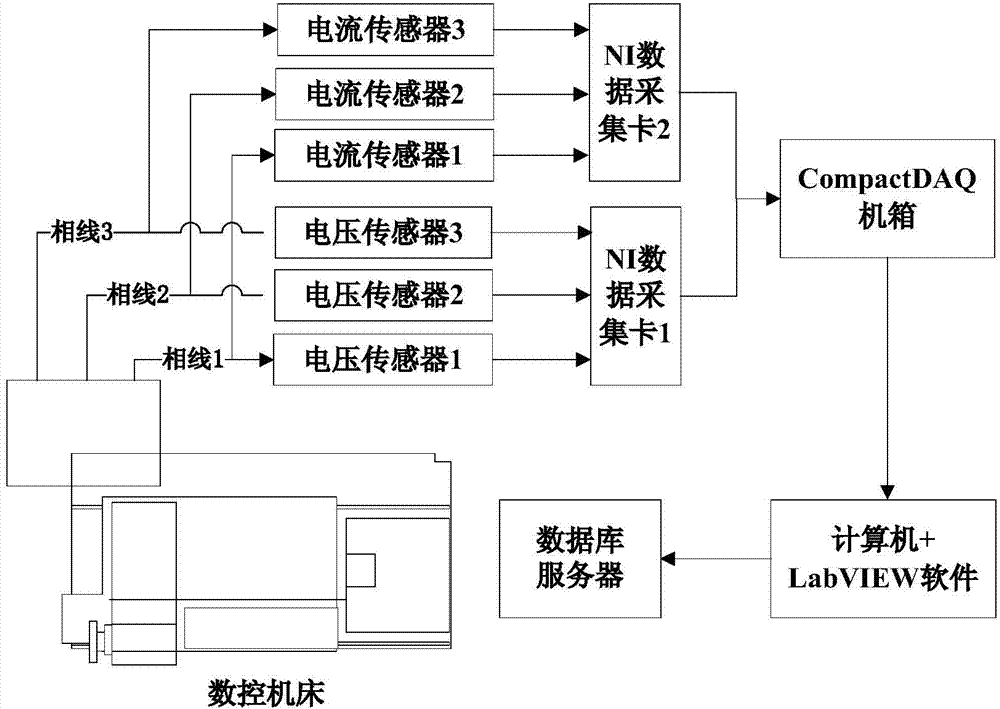

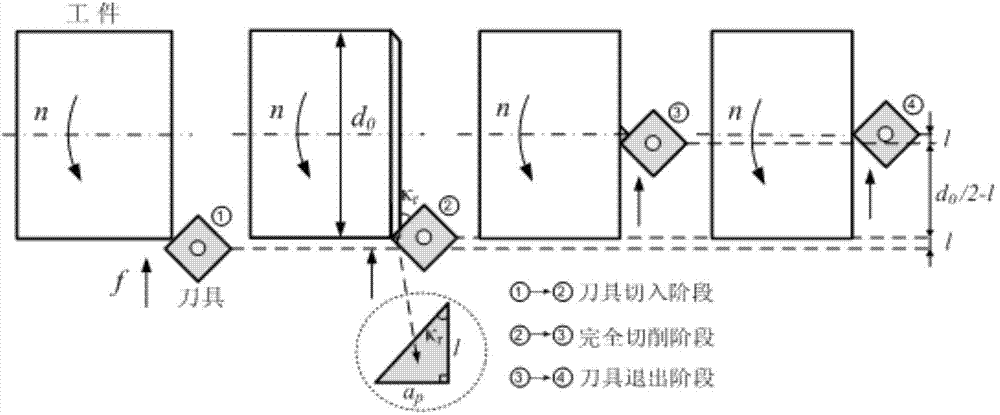

[0054] Step 1. Obtain the value combination of cutting elements. For each combination of values, perform idle cutting and collect the power of idle cutting of the machine tool in real time, and then perform cutting according to the same combination of cutting elements. The combination of values The corresponding variable cutting rate process is divided into several sub-intervals with equal time intervals, and the cutting power of the machine tool in each sub-interval is collected in real time.

[0055] The embodiment of the present invention takes the end face process as an example, and the value combinations of different cutting elements are shown in Table 1.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com