Silicon wafer transfer device

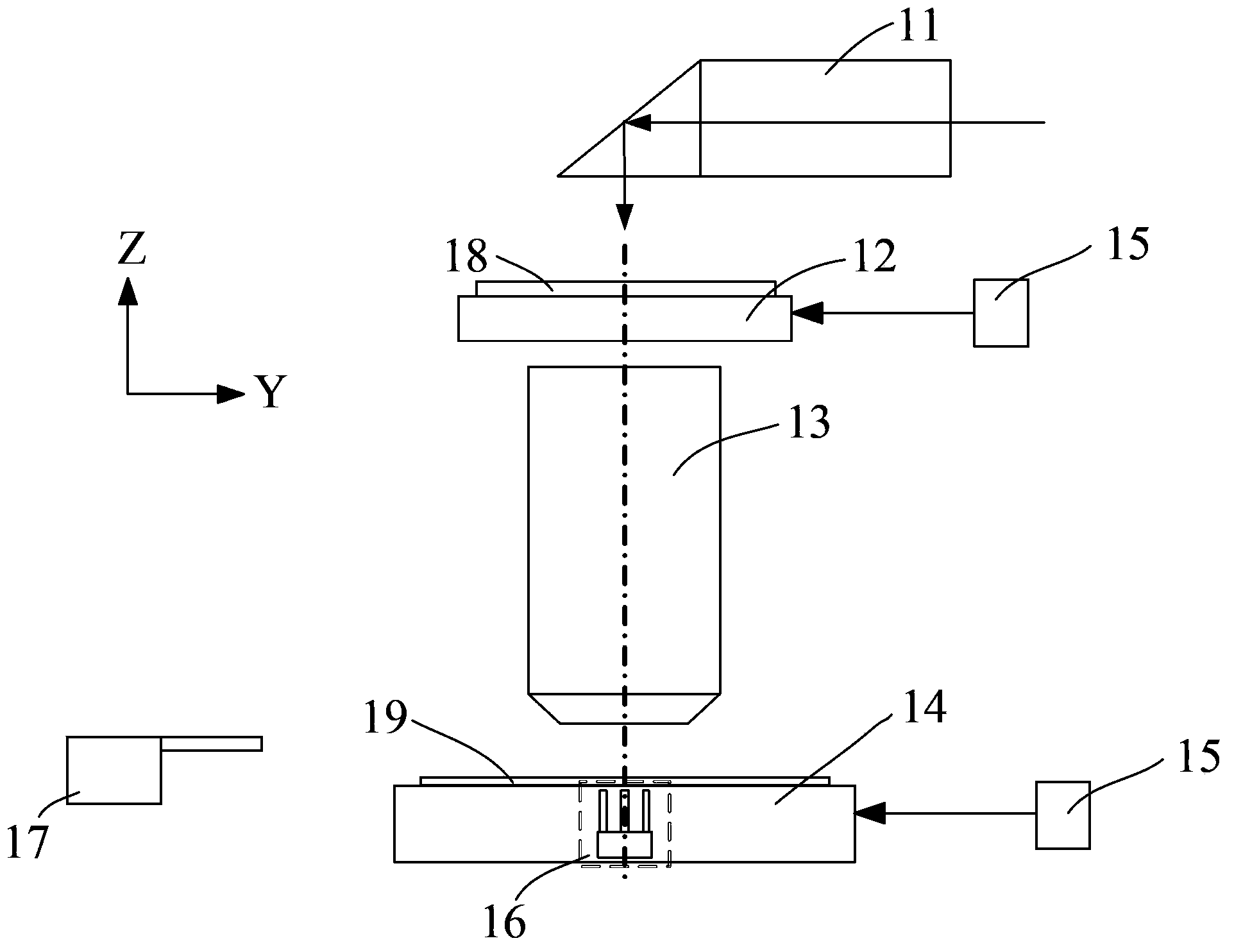

A handover device and silicon wafer technology, which is applied in the direction of exposure device, transportation and packaging, conveyor objects, etc. in the photolithographic process, can solve hidden dangers and safety problems, achieve low cost, simple structure, and eliminate potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

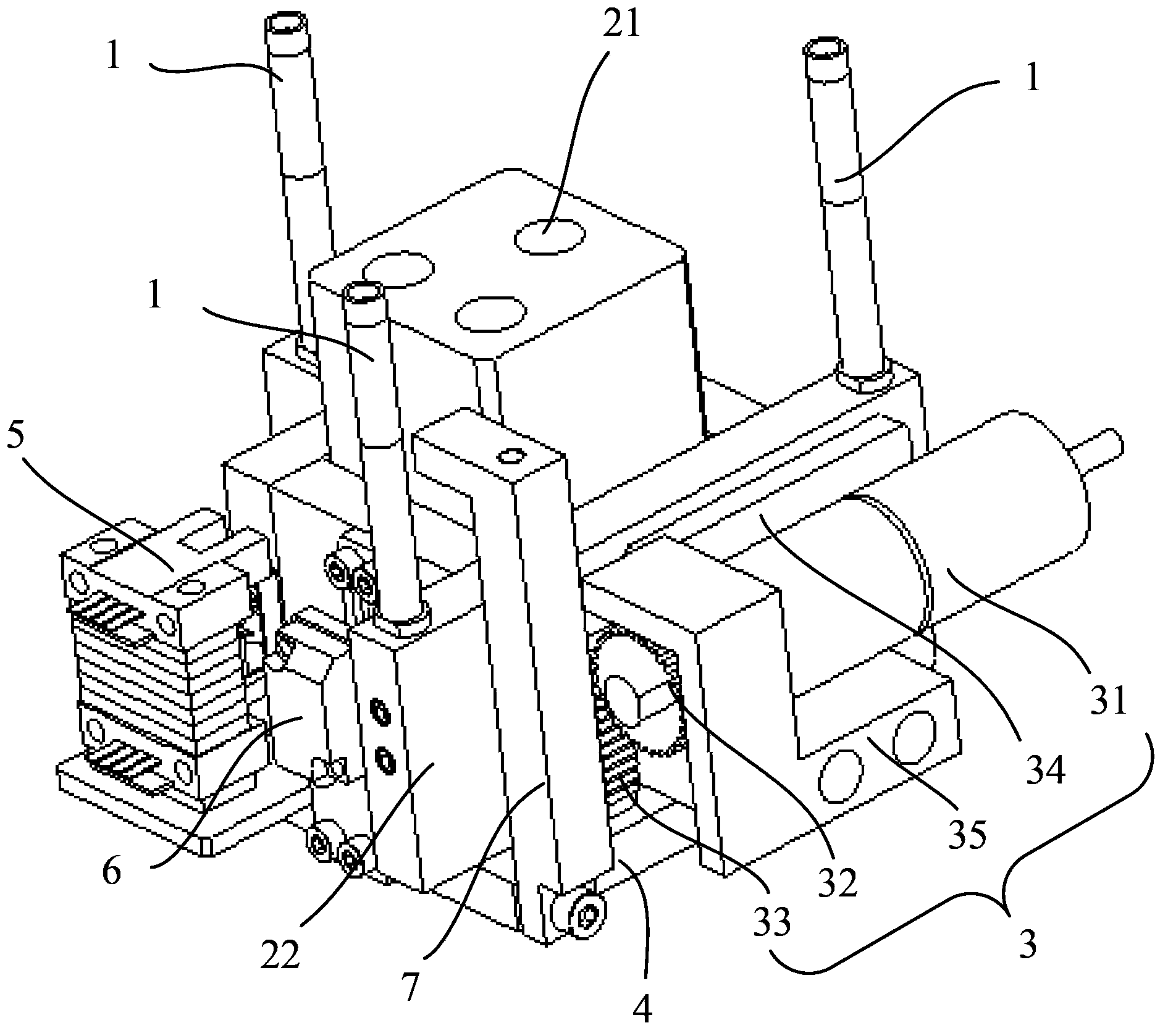

[0037] Please refer to image 3 , and combined with Figure 4~5 , the silicon wafer handover device of this embodiment includes a hand 1 , an air bearing rail device 2 , a driving mechanism 3 and a base 4 . Wherein, the splicing hand 1 is fixed on the top of the air-floating guide rail device 2, the air-floating guide rail device 2 and the driving mechanism 3 are fixed on the base 4, and the driving mechanism 3 drives the air-floating guiding rail Device 2 moves. Specifically, the splicing hand 1 is used for absorbing silicon wafers and providing a supporting surface for the silicon wafers; The splicing hand 1; the driving mechanism 3 provides the driving force for the vertical movement of the silicon wafer handover device, and provides a frictionless linear guide function for the vertical movement of the silicon wafer handover device. Therefore, the silicon wafer transfer device in this embodiment solves the friction problem of the guide mechanism in the prior art. At the ...

Embodiment 2

[0052] The difference between this embodiment and Embodiment 1 lies in the structural shape of the air-floating guide rail device.

[0053] Please refer to Figure 6 , in this embodiment, the air-floating rail device 2' includes an air-floating rail stator 21' and an air-floating rail mover 22', wherein the air-floating rail stator 21' is a prism, and the air-floating rail mover 22' It is a hollow prism or cuboid, and the shape of the hollow part corresponds to the shape of the air bearing guide rail stator 21'. Similarly, the air-floating guide rail device 2' in this embodiment can effectively prevent deflection between the air-floating guide rail movable stator 21' and the air-floating guide rail mover 22', avoiding damage to the silicon wafer or the upper surface of the splicing hand. If it is not parallel to the base, it will affect the subsequent photolithography process.

Embodiment 3

[0055] The difference between this embodiment and Embodiment 1 and Embodiment 2 is that the structure and shape of the air-floating guide rail device and its airflow channel are different.

[0056] Please refer to Figure 7 , in this embodiment, the air-floating rail device 2" includes an air-floating rail stator 21" and an air-floating rail mover 23", the air-floating rail stator 21" is a cylinder, and the air-floating rail mover 23" It is a cylinder or a cuboid, and the shape of the hollow part corresponds to the shape of the air bearing guide rail stator 21". Preferably, an anti-deflection device 22" is provided between the air-floating guide rail mover 23" and the air-floating guide rail stator 21", so as to prevent the air-floating guide rail stator 21" from contacting the air-floating guide rail mover. 23" deflection. Similarly, the air-floating guide rail device 2" can effectively prevent deflection between the air-floating guide rail movable stator 21" and the air-flo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com