An off-axis unobstructed extreme ultraviolet projection lithography objective

An unobstructed, extreme ultraviolet technology, applied in optics, optical components, instruments, etc., can solve problems such as inability to meet extreme ultraviolet high-resolution imaging requirements, unfavorable processing and manufacturing, and failure to achieve imaging accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in detail below with reference to the accompanying drawings and examples.

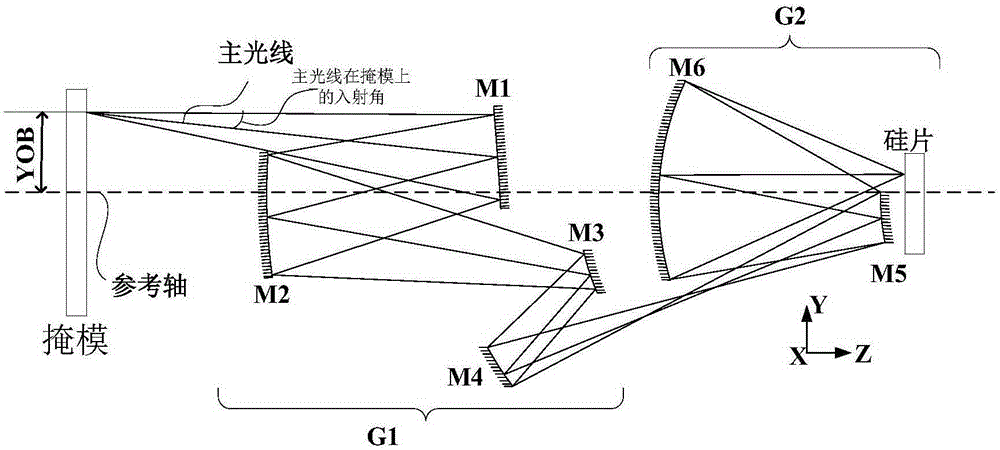

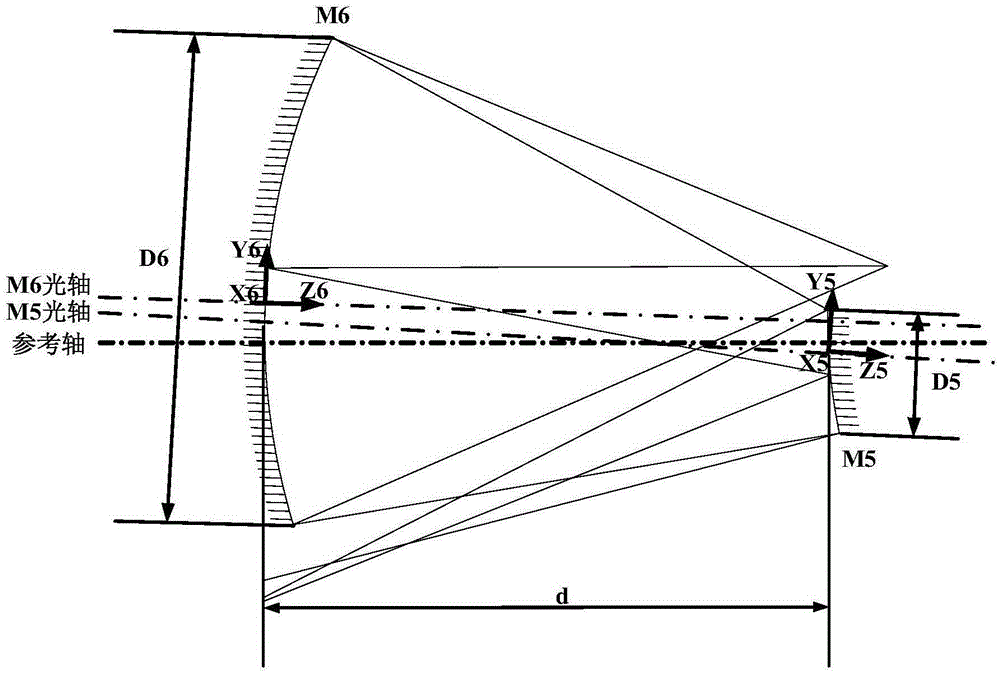

[0045] Such as figure 1 As shown, the extreme ultraviolet projection lithography objective lens of the present invention is an off-axis optical system, and has no rotational symmetry axis, its object plane is the plane where the mask is located, and the image plane is the plane where the silicon wafer is located; the objective lens includes a first lens group And the second mirror group, wherein the first mirror group includes four mirrors: the first mirror M1, the second mirror M2, the third mirror M3 and the fourth mirror M4; the second mirror group includes two mirrors , are the fifth mirror M5 and the sixth mirror M6; the positional relationship along the optical path direction is: the first mirror M1, the second mirror M2, the third mirror M3, the fourth mirror M4, and the fifth mirror M5 and the sixth mirror M6.

[0046] The working process of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com