Device capable of automatically separating samples and bottling and having cleaning function

An automatic, sample-loading technology, applied in the cleaning method of tools, cleaning methods and utensils, preparation of samples for testing, etc., can solve the problems of low work efficiency, high labor intensity of operators, cross-contamination of samples and materials, etc. Low labor intensity, avoid cross-contamination of samples, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

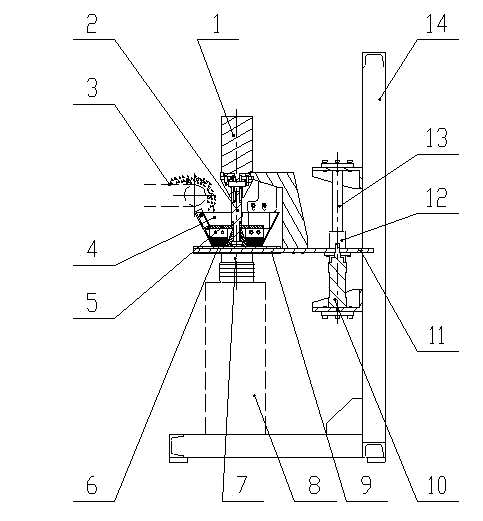

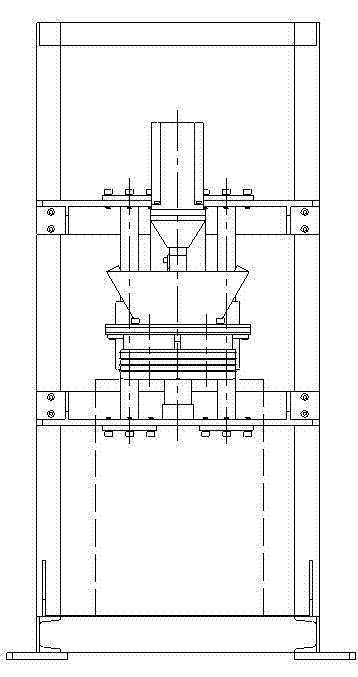

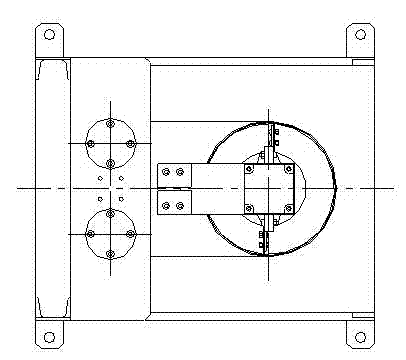

[0010] Such as figure 1 , 2 , 3, the present invention is realized in this way, it comprises stepper motor 1, rotating shaft 2, conveying device 3, two sub-basins 4, swing arm 5, brush 6, sample bottle 7, bottle rack 8, sealing gasket 9 , cylinder 10, platform 11, linear bearing 12, linear polished rod 13, frame 14, its structural feature is that frame 14 is provided with linear bearing 12, linear polished rod 13, linear bearing 12 is connected with platform 11, and platform 11 is connected with cylinder 10; The platform 11 is provided with a two-part basin 4, the conveying device 3 is aligned with the two-part basin 4, and the two-part basin 4 is provided with a rotating shaft 2, the upper part of the rotating shaft 2 is connected to the stepping motor 1, and the lower part is connected to the swing arm 5, and the swing arm 5 is provided with a brush 6. The brush 6 contacts the bottom and the inner wall of the bifurcated basin 4. A sealing gasket 9 is provided under the plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com