Stepped steel ball lock hydraulic cylinder

A steel ball lock and hydraulic cylinder technology, which is applied in the field of locking hydraulic cylinders, can solve the problems of high oil source and oil circuit requirements, low yield and high processing difficulty, avoiding the problem of unreliable locking, small occupied space, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

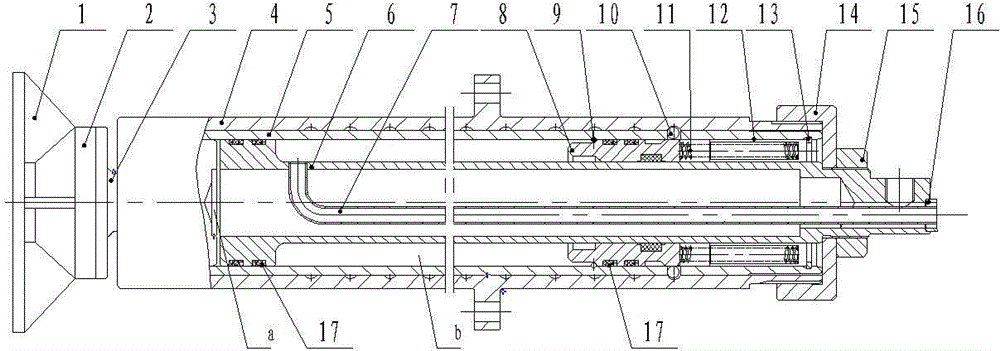

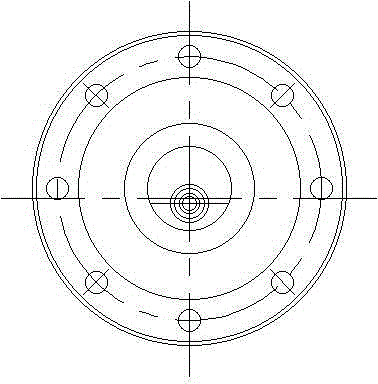

[0027] Such as Figure 1-Figure 3 As shown, there is a graded steel ball locking hydraulic cylinder, including an outer cylinder 4, an inner cylinder 5, a piston rod 6, an oil pipe 7, a locking piston 8, a steel ball 10, a spring 11, a spring seat 12 and a cylinder cover 14. The outer cylinder 4 is threadedly connected with the cylinder head 14, and the inner wall of the outer cylinder 4 is provided with multiple radial grooves. , the outer wall of the inner cylinder 5 is provided with a circle of radial circumferential holes that can place steel balls 10, the piston rod 6 and the locking piston 8 are all arranged in the inner chamber of the inner cylinder 5, and one end of the piston rod 6 is connected 5. The inner wall is clearance fit, and the other end passes through the cylinder head 14 and is fixed by the lock nut 15. The inner wall of the locking piston 8 is in clearance fit with the piston rod 6 and the inner wall can be connected with the inner cavity of the piston ro...

Embodiment 2

[0038] Such as Figure 1-Figure 3 As shown, there is a graded steel ball locking hydraulic cylinder, including an outer cylinder 4, an inner cylinder 5, a piston rod 6, an oil pipe 7, a locking piston 8, a steel ball 10, a spring 11, a spring seat 12 and a cylinder cover 14. The outer cylinder 4 is threadedly connected with the cylinder head 14, and the inner wall of the outer cylinder 4 is provided with multiple radial grooves. , the outer wall of the inner cylinder 5 is provided with a circle of radial circumferential holes that can place steel balls 10, the piston rod 6 and the locking piston 8 are all arranged in the inner chamber of the inner cylinder 5, and one end of the piston rod 6 is connected 5. The inner wall is clearance fit, and the other end passes through the cylinder head 14 and is fixed by the lock nut 15. The inner wall of the locking piston 8 is in clearance fit with the piston rod 6 and the inner wall can be connected with the inner cavity of the piston ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com