Repeated Annealing Spheroidization Method for Flaky α in Mixed Microstructure of Near-α Titanium Alloy

A titanium alloy and tissue technology, applied in the field of heat treatment of materials, can solve problems such as high cost and complicated process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

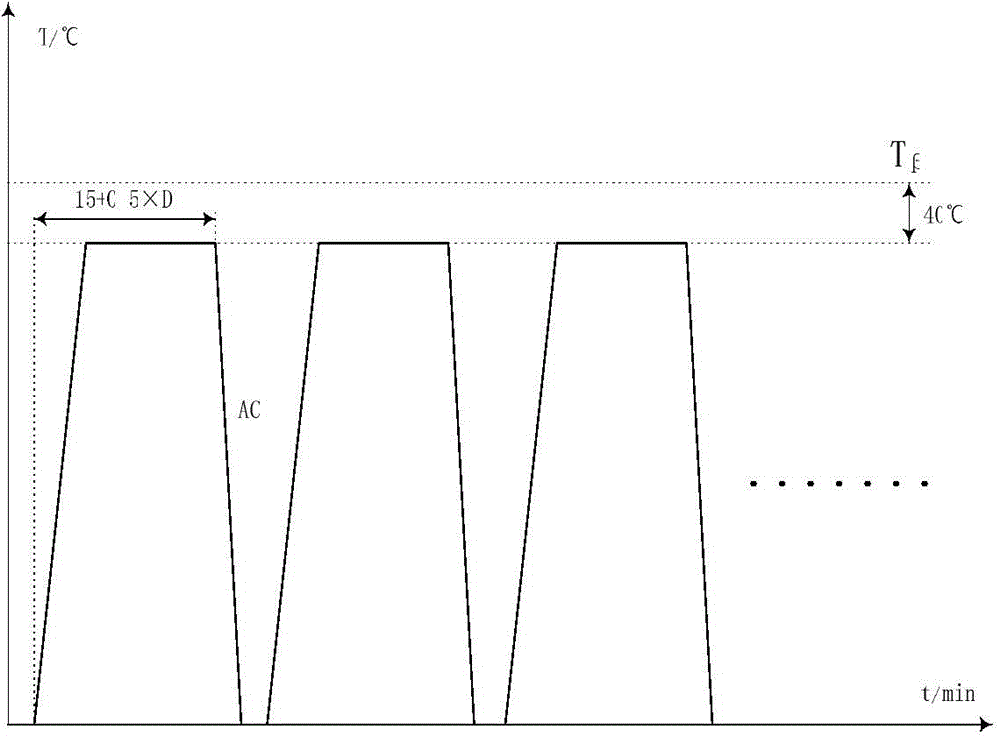

[0015] Heat the resistance furnace to 940°C, and put the mixed structure TA15 titanium alloy sample with a size of Φ10×15mm into the resistance furnace for heat preservation. The holding time is 15min+0.5min / mm×D, where D is the minimum dimension of the sample. In this embodiment, the minimum external dimension of the sample is D=10mm, so the holding time is 20min. After the heat preservation is over, the sample is taken out and air-cooled to complete the first annealing process.

[0016] Heat the resistance furnace to 940°C, put the mixed structure TA15 titanium alloy sample that has been annealed for the first time into the resistance furnace, keep it warm for 20 minutes, take out the sample and air-cool it, and complete the second annealing process.

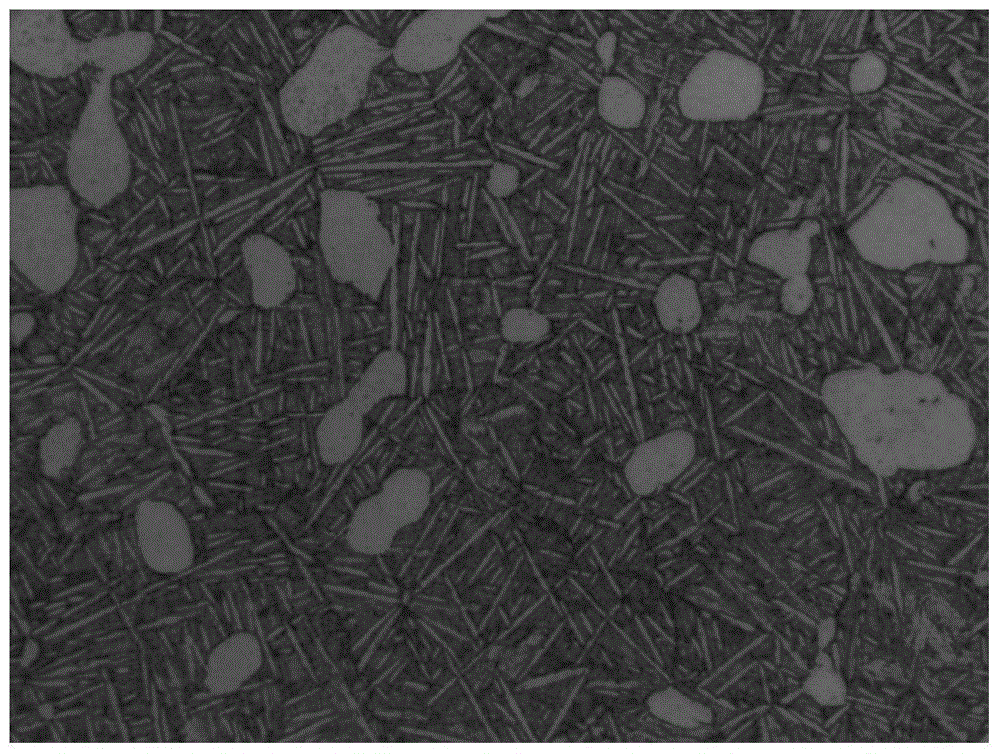

[0017] The above annealing process is repeated, and the third annealing to the fifth annealing are performed sequentially. Repeat the above annealing process, the equiaxed α content in the TA15 titanium alloy after 5 times o...

Embodiment 2

[0019] Heat the resistance furnace to 950°C, and put the mixed structure TA11 titanium alloy sample with a size of Φ20×30mm into the resistance furnace for heat preservation. The holding time is 15min+0.5min / mm×D, where D is the minimum dimension of the sample. In this embodiment, the minimum external dimension of the sample is D=20mm, so the holding time is 25min. After the heat preservation is over, the sample is taken out and air-cooled to complete the first annealing process.

[0020] Heat the resistance furnace to 950°C, put the mixed structure TA11 titanium alloy sample that has been annealed for the first time into the resistance furnace, keep it warm for 25 minutes, take out the sample and air-cool it, and complete the second annealing process.

[0021] Repeat the above annealing process, and perform the third and fourth annealing in sequence. After 4 times of annealing, the equiaxed α content in the TA11 titanium alloy changed from 10% to 25%, and the equiaxed α con...

Embodiment 3

[0023] Heat the resistance furnace to 940°C, and put a mixed structure TA15 titanium alloy sample with a size of 55mm×55mm×12mm into the resistance furnace to keep it warm. The holding time is 15min+0.5min / mm×D, where D is the minimum dimension of the sample. In this embodiment, the minimum external dimension of the sample is D=12mm, so the holding time is 21 minutes. After the heat preservation is over, the sample is taken out and air-cooled to complete an annealing process.

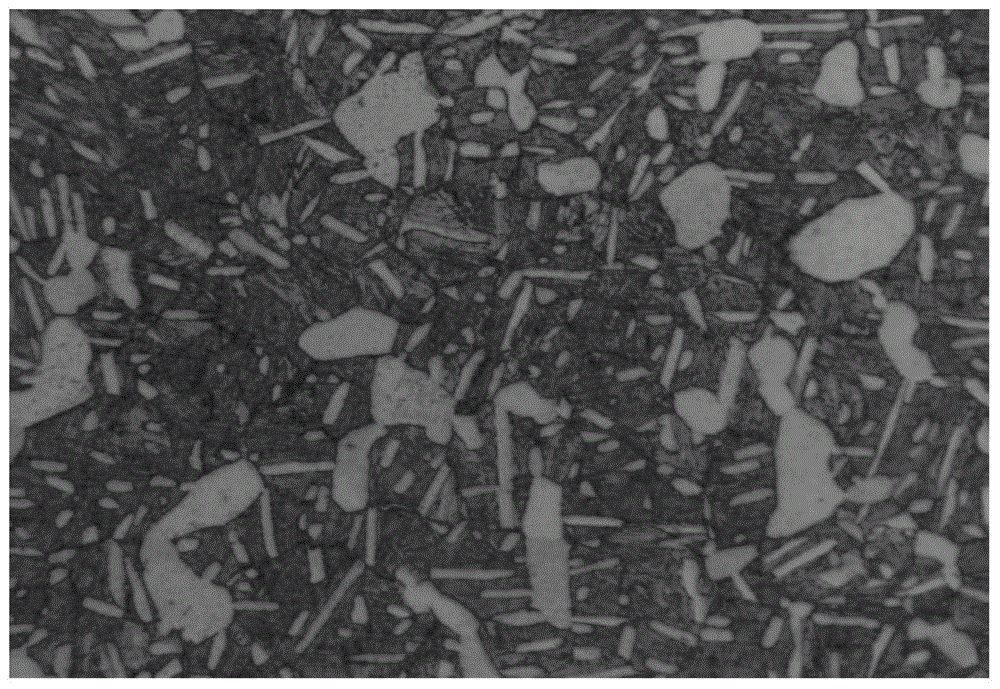

[0024] Heat the resistance furnace to 940°C, put the mixed structure TA15 titanium alloy sample that has been annealed for the first time into the resistance furnace, keep it warm for 21 minutes, take out the sample and cool it in air, and complete the second annealing process. The equiaxed α content in TA15 titanium alloy changed from 10% to 15%, and the equiaxed α content increased by 5%. Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com