Vertical furnace carbonization chamber with internal gas collection cavities

A carbonization chamber and gas collection chamber technology, applied in the field of continuous vertical furnaces for low-rank coal drying, can solve the problems of poor air permeability of the material layer and difficult separation and treatment, so as to reduce the pressure in the furnace, improve the gas recovery rate, The effect of prolonging the life of the furnace body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

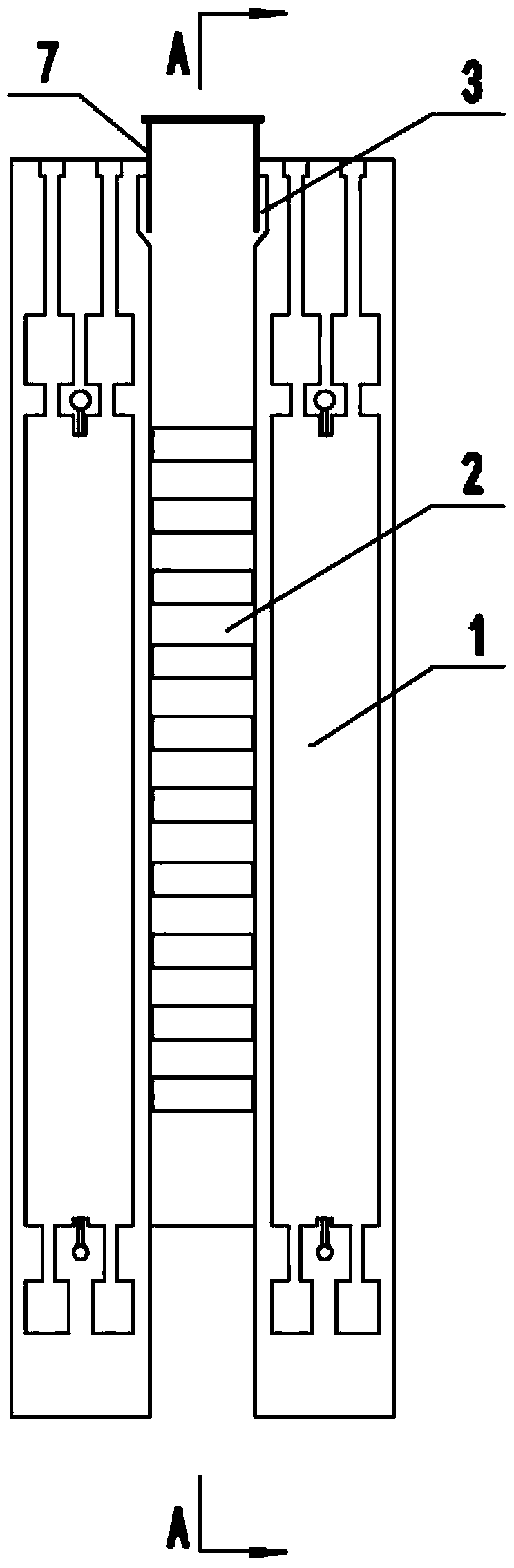

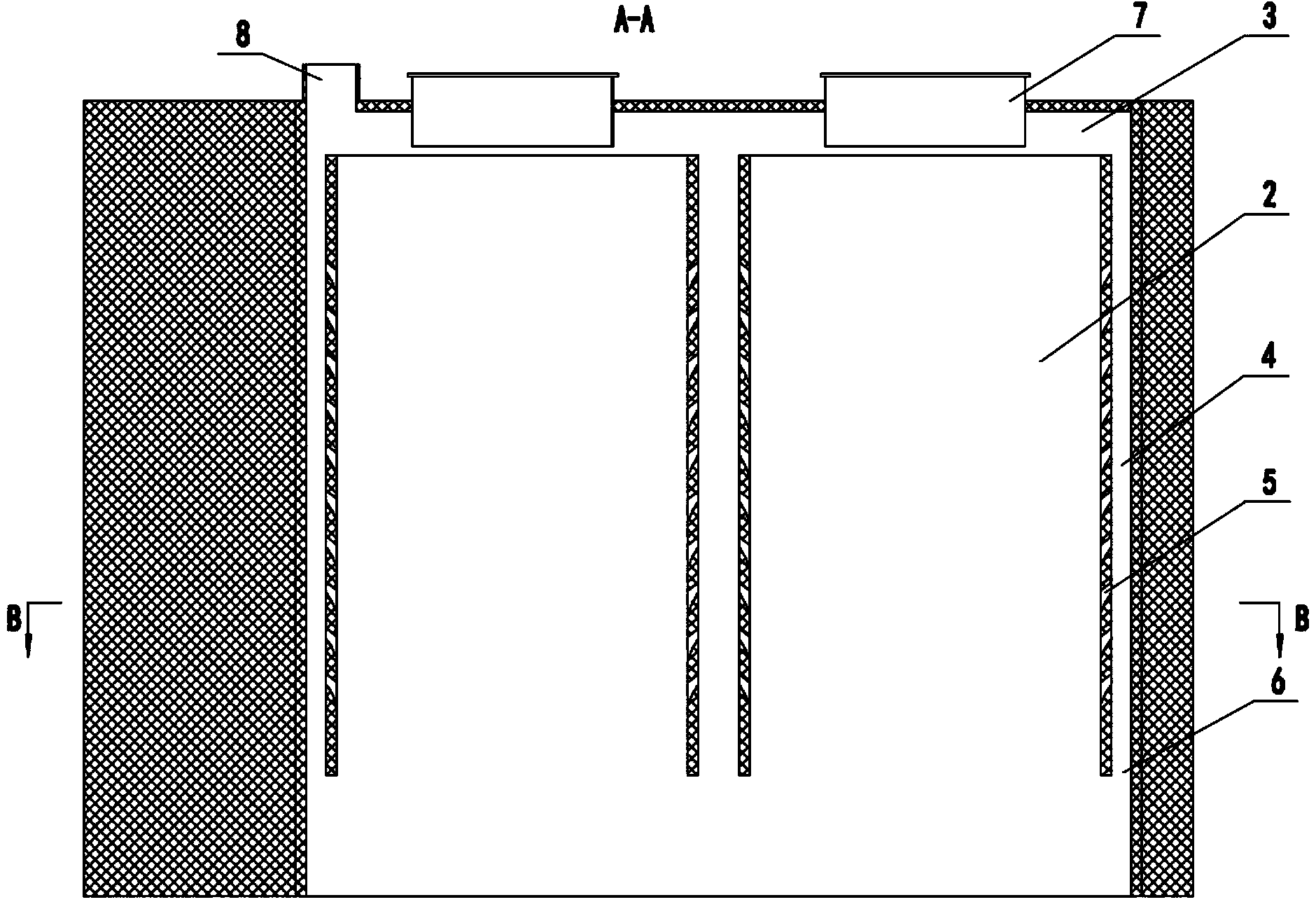

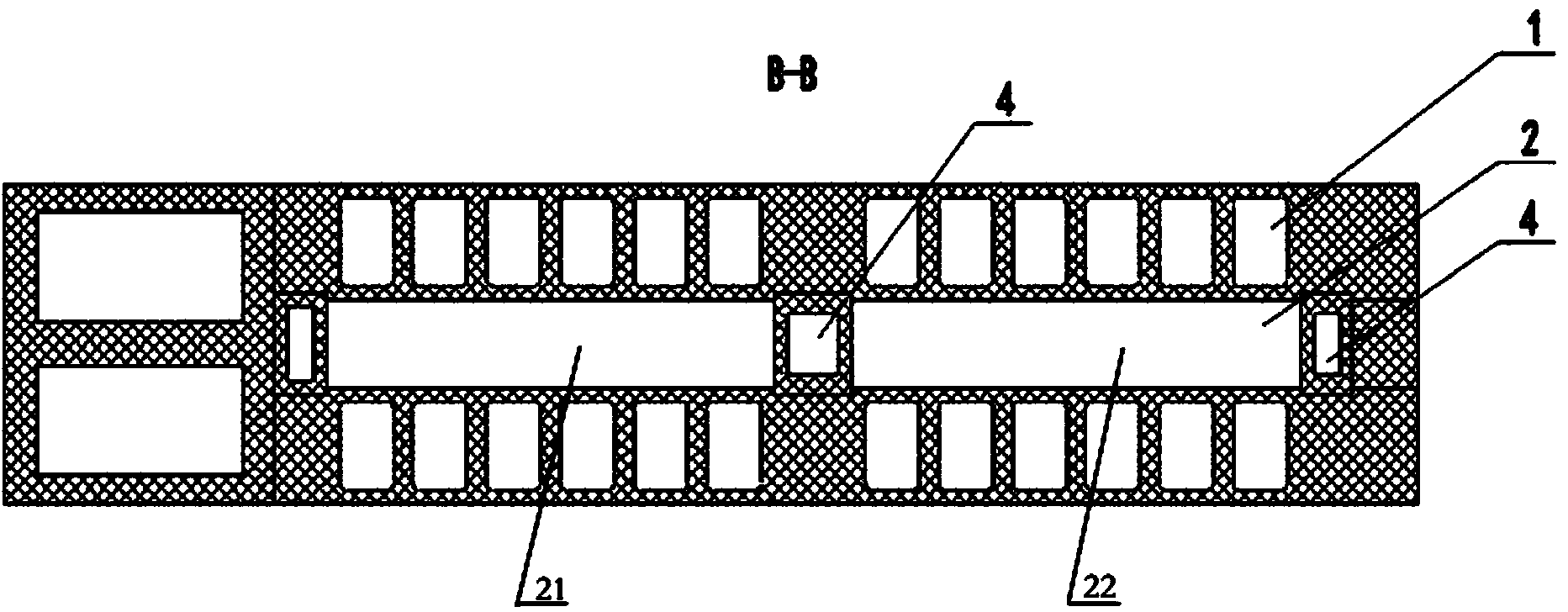

[0025] [Embodiment 1] A kind of specific application structural form of the present invention

[0026] See Figure 1-Figure 3 , is a structural schematic diagram of an embodiment of a vertical furnace carbonization chamber with an inner gas collection chamber according to the present invention, including a combustion chamber 1 21 and a carbonization chamber 2 22, and gas collection chambers are arranged at both ends and / or in the middle of each door carbonization chamber 2 There is a gas outlet hole 5 between the carbonization chamber 2 and the gas collection chamber 4, and the gas outlet hole 5 is set at an interval of 0.5 to 1 meter along the height. 5 is not blocked by the descending coal material, and is conducive to the export of raw gas, and can also prevent the coal material in the carbonization chamber 2 from entering the gas collection chamber 4 through the gas outlet hole 5 . The height of gas outlet hole 5 is 40~100mm.

[0027] The bottom 6 of the gas-collecting c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com