Thermosetting resin composition, and prepreg and laminated board prepared from the resin composition

A resin composition, thermosetting technology, applied in the direction of synthetic resin layered products, lamination, lamination devices, etc., to achieve the effect of good layability, good precision control, and low resin fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

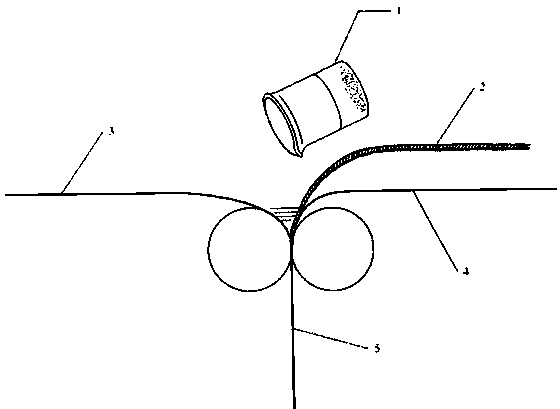

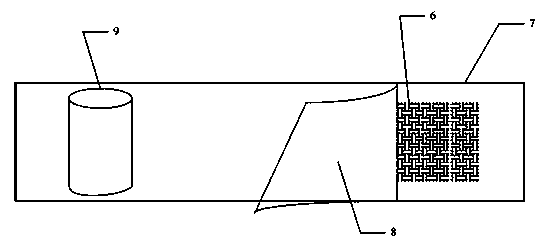

[0024] The preparation method of the prepreg of the present invention can be specifically described as:

[0025] 1) Resin preparation

[0026] Weigh each component according to the formula, place in a blender and stir until all components are evenly mixed, and set aside.

[0027] 2) Prepreg preparation (can be selected from method 1 or method 2 below)

[0028] method 1

[0029] Prepare the fiber cloth (glass fiber, carbon fiber, aramid fiber or other fiber cloth) to be pre-impregnated, the size is 15cm*100cm, put it on the release paper of 20cm*110cm, dip the above prepared resin with a brush, brush Put it on the fiber cloth, after all the fibers are soaked by resin, cover it with another piece of 20cm*110cm release paper, and then use a 3KG roller to roll back and forth on the release paper 5 times. The rolled samples can be used after being placed at room temperature for 24 hours or baked at 80 degrees for 15 minutes.

[0030] Method 2

[0031] Prepare fiber cloth (glas...

Embodiment 1-5

[0036] A thermosetting resin composition, by solid weight, comprises the following components, as shown in the table below:

[0037] Table 1: Composition formulation (parts by weight)

[0038] A1 A2 B1 B2 C1 C2 D1 D2 E F Example 1 100 / 12 / 10 / 5 / / / Example 2 / 100 / 10 / 15 / 6 / 3 Example 3 100 / 20 / / 2 1 / 5 / Example 4 100 / 22 / 27 / / 16 / / / Example 5 / 100 8 10 10 10 / 10 5 5

[0039] Note: In the above table, the basis of parts by weight is based on the weight of epoxy resin (A) as 100 parts by weight.

[0040] The meaning of each letter in the table is:

[0041] A epoxy resin:

[0042] A1: E51; (epoxy value 0.51)

[0043]A2: E44; (epoxy value 0.44)

[0044] B room temperature curing agent:

[0045] B1: EC301 (polyether amine); (amine equivalent is 61g / equivalent)

[0046] B2: EC280 fatty amine; (amine equivalent is 52g / equivalent)

[0047] C high tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com