Method and device for oxidative adjustment of plutonium valence with NOx

A valence and oxidant technology, applied in the field of NOx oxidation to adjust plutonium valence, can solve the problems of low utilization rate and unstable pressure, and achieve the effect of improving utilization rate, stable pressure and reducing disposal burden.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

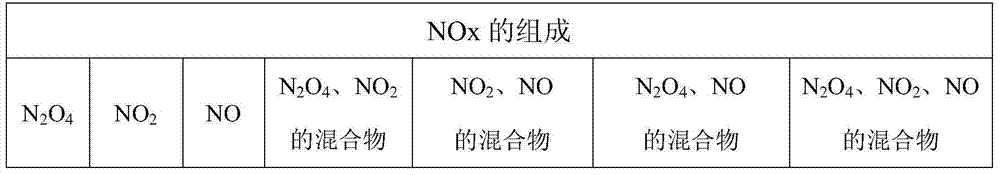

[0031] NO x A method for adjusting the valence state of plutonium by oxidation. The method uses NOx and oxygen-containing gas as an oxidant to destroy the reducing agent in the Pu(III) feed solution and oxidizes Pu(III) to Pu(IV). The gas containing oxygen is air, and the amount of air admitted is twice that of NOx. The composition of NOx is as follows:

[0032]

Embodiment 2

[0034] The method is the same as in Example 1, except that the gas containing oxygen used is oxygen, and the amount of oxygen introduced is 0.5 times that of NOx.

Embodiment 3

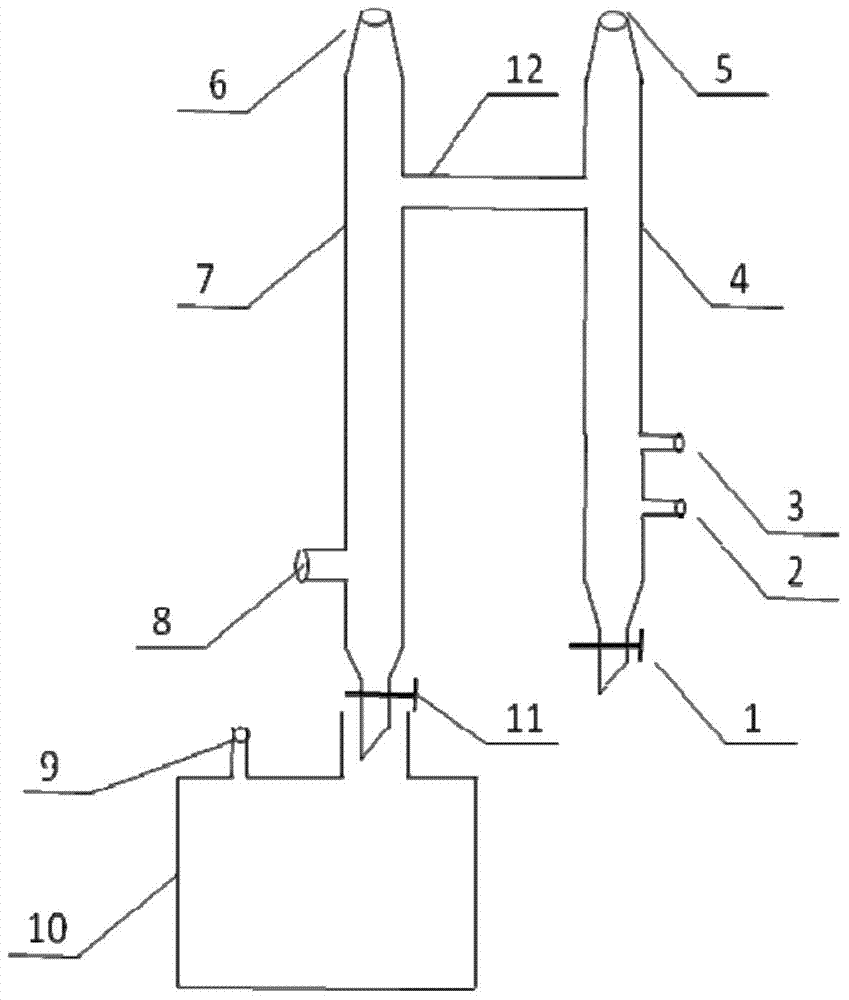

[0036] NO x A device for adjusting the valence state of plutonium by oxidation, the device includes a Pu(III) oxidation column 4 and a nitrous acid removal column 7, the Pu(III) oxidation column 4 is connected to the nitrous acid removal column 7 through a feed liquid delivery pipe 12 at the upper part, The key is that the first tail gas discharge port 5 and the second tail gas discharge port 6 are respectively placed on the top of the Pu(Ⅲ) oxidation column 4 and the nitrous acid removal column 7, and the lower part of the Pu(Ⅲ) oxidation column 4 is provided with an oxidant inlet 2 and Pu (Ⅲ) feed liquid inlet 3, the lower part of the nitrous acid removal column 7 is equipped with an air inlet 8, and the bottom is connected with the feed liquid storage tank 10, wherein the oxidant is a mixture of NOx and oxygen-containing gas, and NOx is N 2 o 4 , NO 2 , NO, or a mixture of any two or three, and the gas containing oxygen is air.

[0037] The oxidant inlet 2 is located bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com