Efficient aircraft carrier with seamless steam catapult

A catapult and steam technology, which is applied to aircraft carriers, launching/dragging transmissions, special-purpose ships, etc., can solve the problems of aircraft carriers such as poor maneuverability, increased speed, and large space occupation, and reduce the difficulty of processing and manufacturing. The effect of reducing time and consumption, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

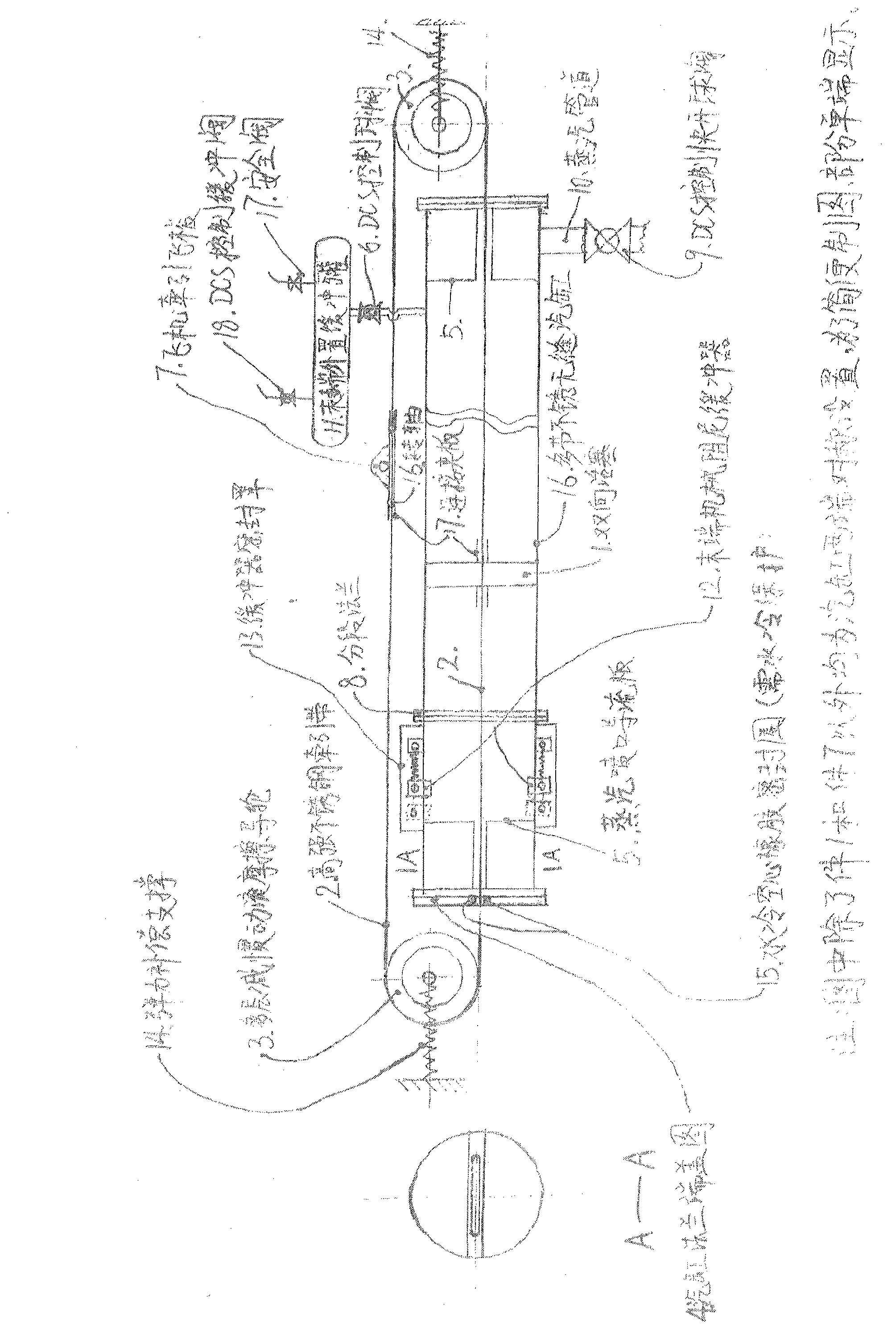

Image

Examples

Embodiment Construction

[0019] Multi-section stainless seamless cylinder 16 can be made to DN160, 50Kg / cm 2 ;DN250, 20Kg / cm 2 ;DN350, 10Kg / cm 2 ;DN500, 5Kg / cm 2 . The maximum operating pressure of the cylinder can also reach twice that of the American slotted cylinder, that is, a single cylinder can meet the needs of use. Four-stage pressure cylinders are used to eject in order from high to low, and the residual pressure can be used as a lift to make full and efficient use of steam. When ejecting, there is a small amount of leakage between the high-strength stainless steel traction belt 2 and the long hole of the cylinder flange end cover 4. The steam can be guided into the recovery condensate pool through the isolation cover, and the loss of fresh water can be minimized during the entire ejection process. It can be achieved that no steam can be seen on the ship deck or in the control room during the entire ejection process, which greatly improves the efficiency of steam use and the sight of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com