Multifunctional precision alternating-current servo swaging machine

An AC servo motor and AC servo technology, applied in forging/pressing/hammering machinery, forging/pressing/hammer devices, hammers, etc., to achieve good stability, long support center distance, and not easy to tilt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

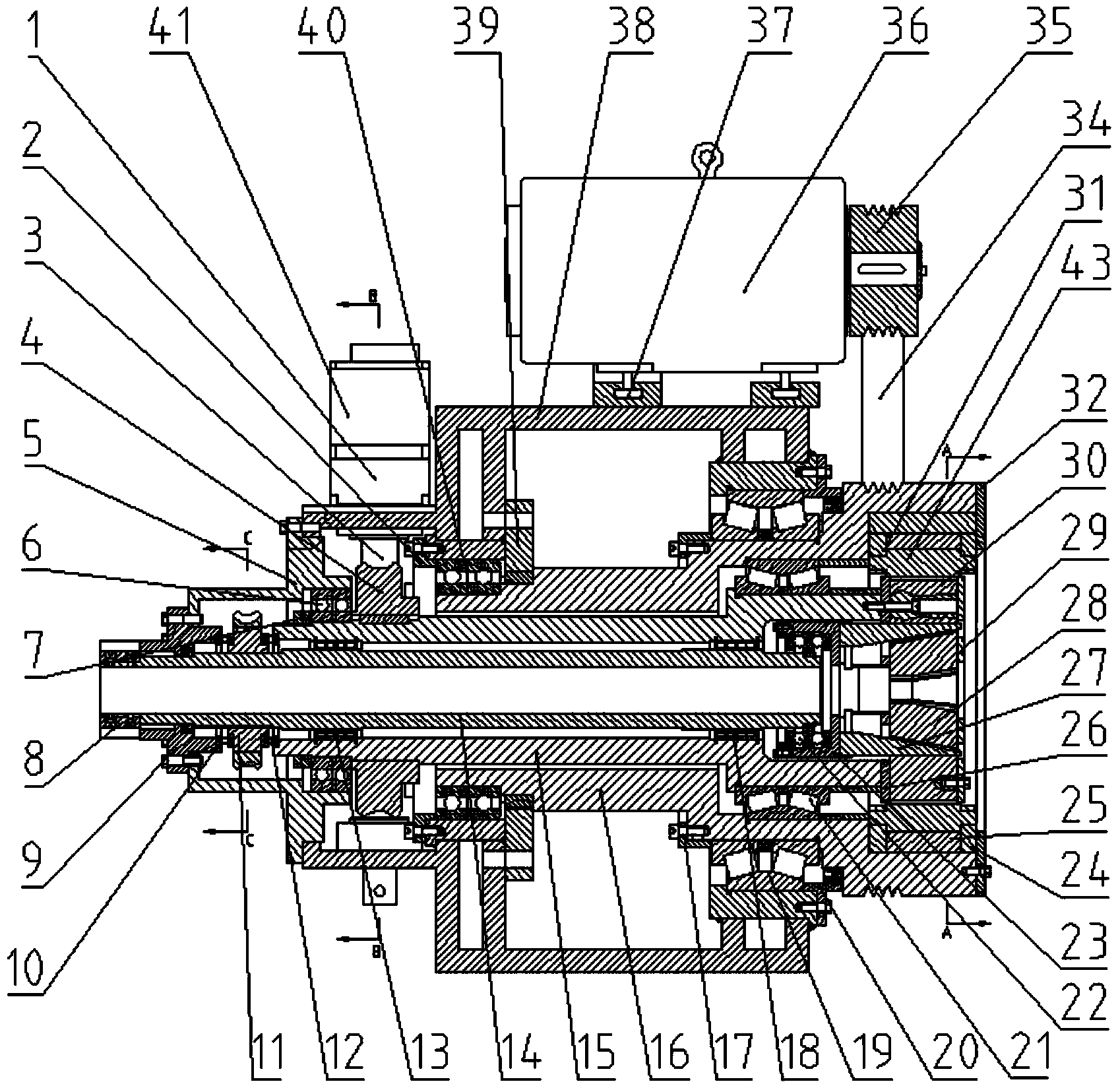

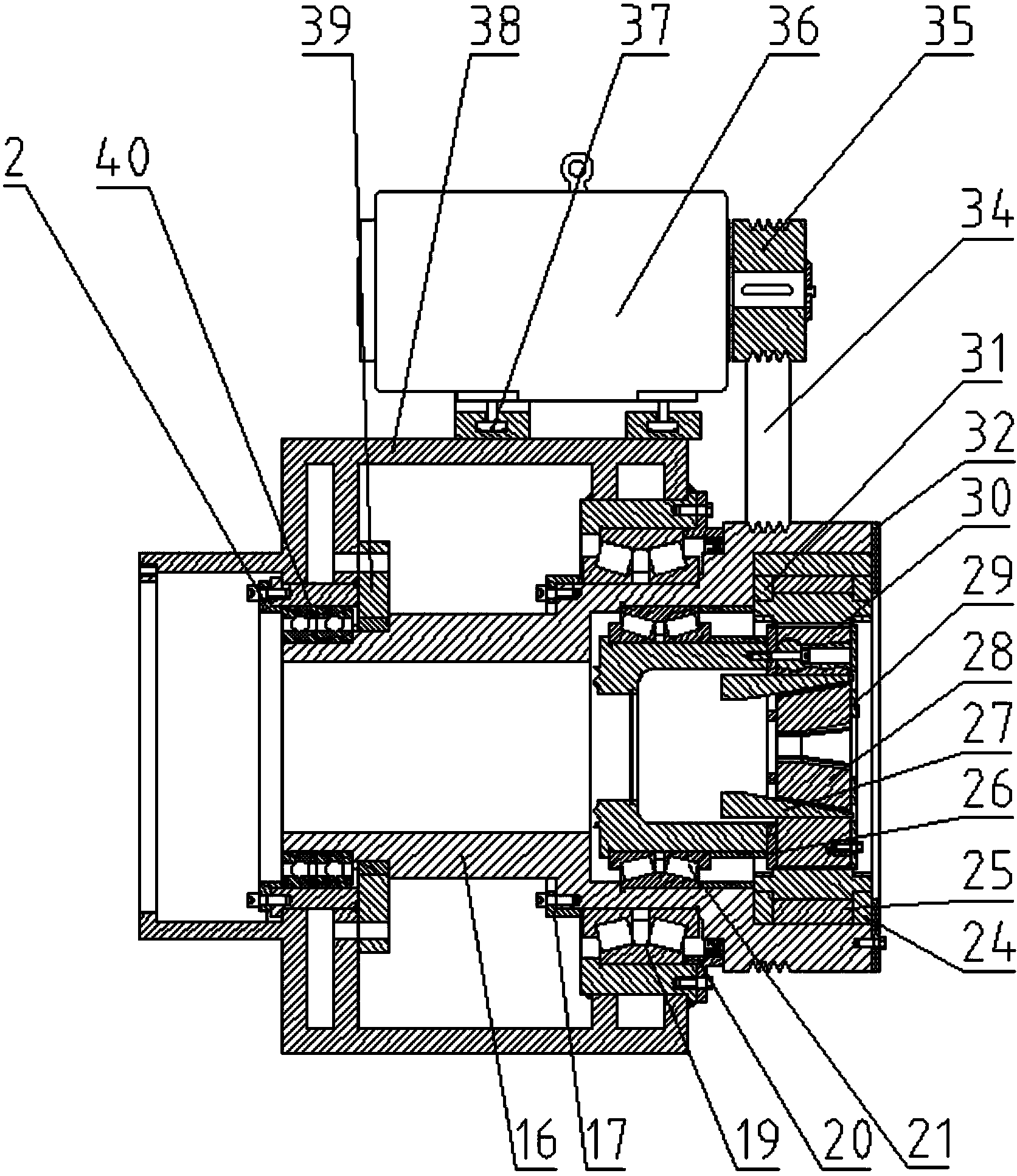

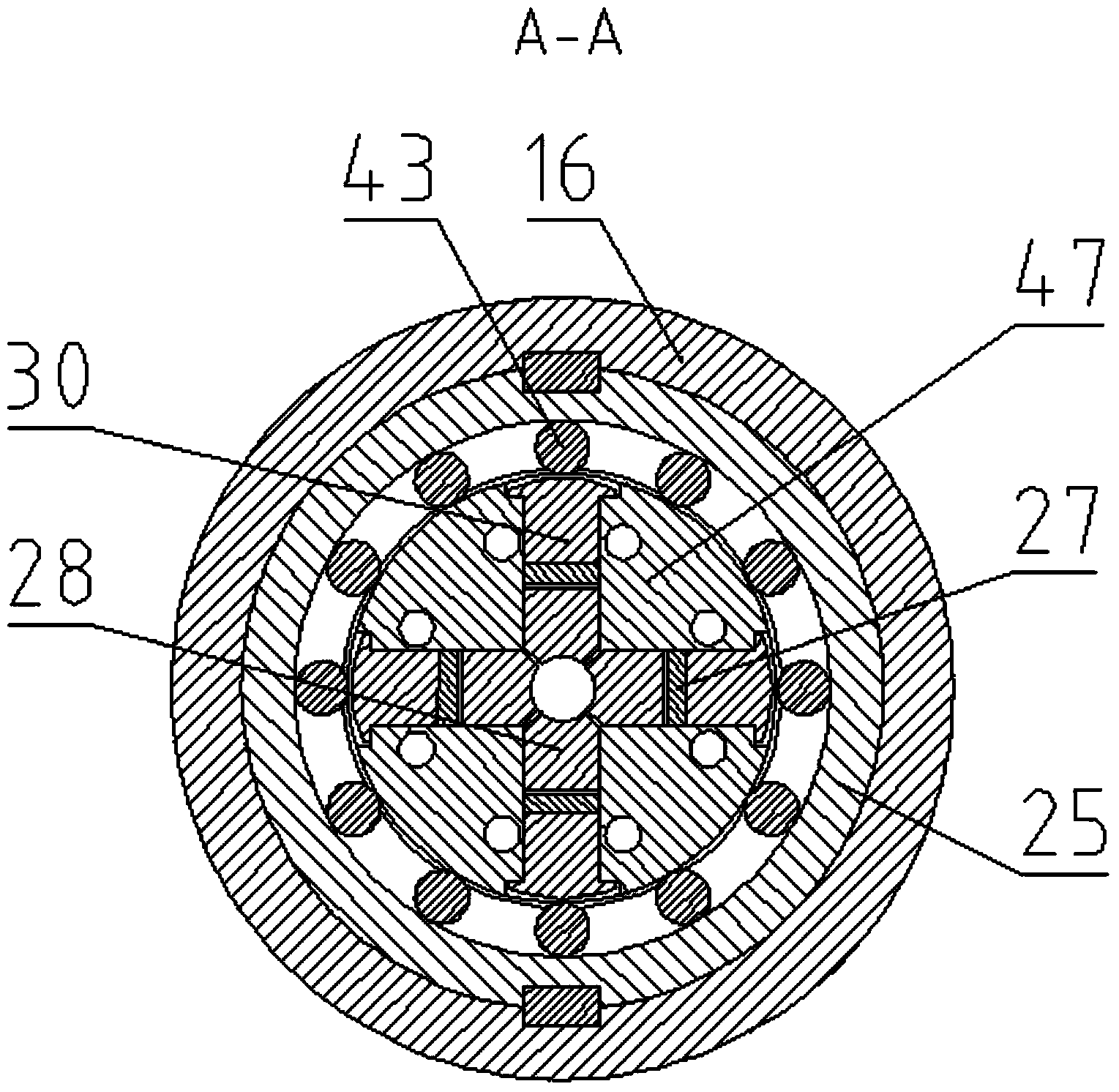

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0025] A multifunctional precision AC servo swaging machine, including a swaging head, a mold rotating system, a diameter reducing system and a fuselage part, the swaging head and the mold rotating system cooperate, and the swaging head, the mold rotating system, and the diameter reducing system are installed on on the fuselage part;

[0026] like figure 1 , figure 2 and image 3 As shown, the swaging head is the main forming part. The swaging head includes a cylinder 16, and the small pulley 35 is connected with the cylinder 16 through a transmission belt 34. The cylinder 16 is installed on the cylinder 16 through the first double-row tapered roller bearing 19 and the first rolling bearing 40. In the fuselage 38, the first small end cover 17 is installed on the cylinder 16 to fix the first double-row tapered roller bearing 19, the flywheel 39 is installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com