A device for removing iron filings in the inner cavity of the rear axle housing

A technology for the inner cavity of the shell and the rear axle, which is applied in the direction of cleaning methods and appliances, chemical instruments and methods, etc., can solve problems such as product failure, iron filings retention, shape or positioning changes, etc., to improve the scope of application, strong impact, and Good clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Example 1: Taking JMC Transit 11B and NKR 8B rear axle housings as examples, the assembling aperture of the main reducer assembly after the machining of the 11B rear axle housing is 227MM, and the radius of the outer circle of the housing is R148MM. The total length is 1816MM; the assembly aperture of the main reducer assembly of the rear axle housing of the 8B type axle housing is 274MM, the outer circle radius of the housing is R168MM, and the total length of the bridge body is 1586MM.

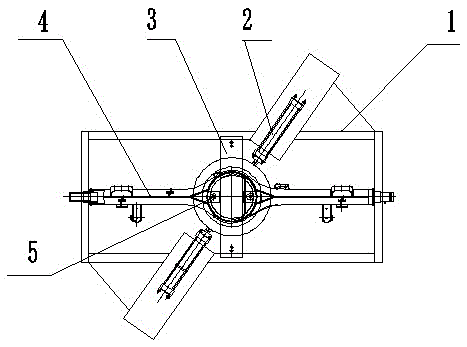

[0015] The device for removing iron filings in the cavity of the rear axle housing includes a support frame body 1, a positioning mechanism 3, a striking cylinder 2 and a corresponding electrical control system. The positioning mechanism 3 is connected and relatively fixed with the support frame body 1 by welding, and the striking cylinder 2 is fixedly connected with the support frame body 1 through bolts. The positioning mechanism 3 is also provided with a pair of positioning nylon b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com