Test tube clamp

A technology of test tube clamps and test tubes, which is applied in the field of experimental equipment, can solve the problems of increased test tube wear, danger to experimenters, wrong gripping and pinching of upper clamps, etc., and achieves the effects of simple structure, convenient use, and avoidance of falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

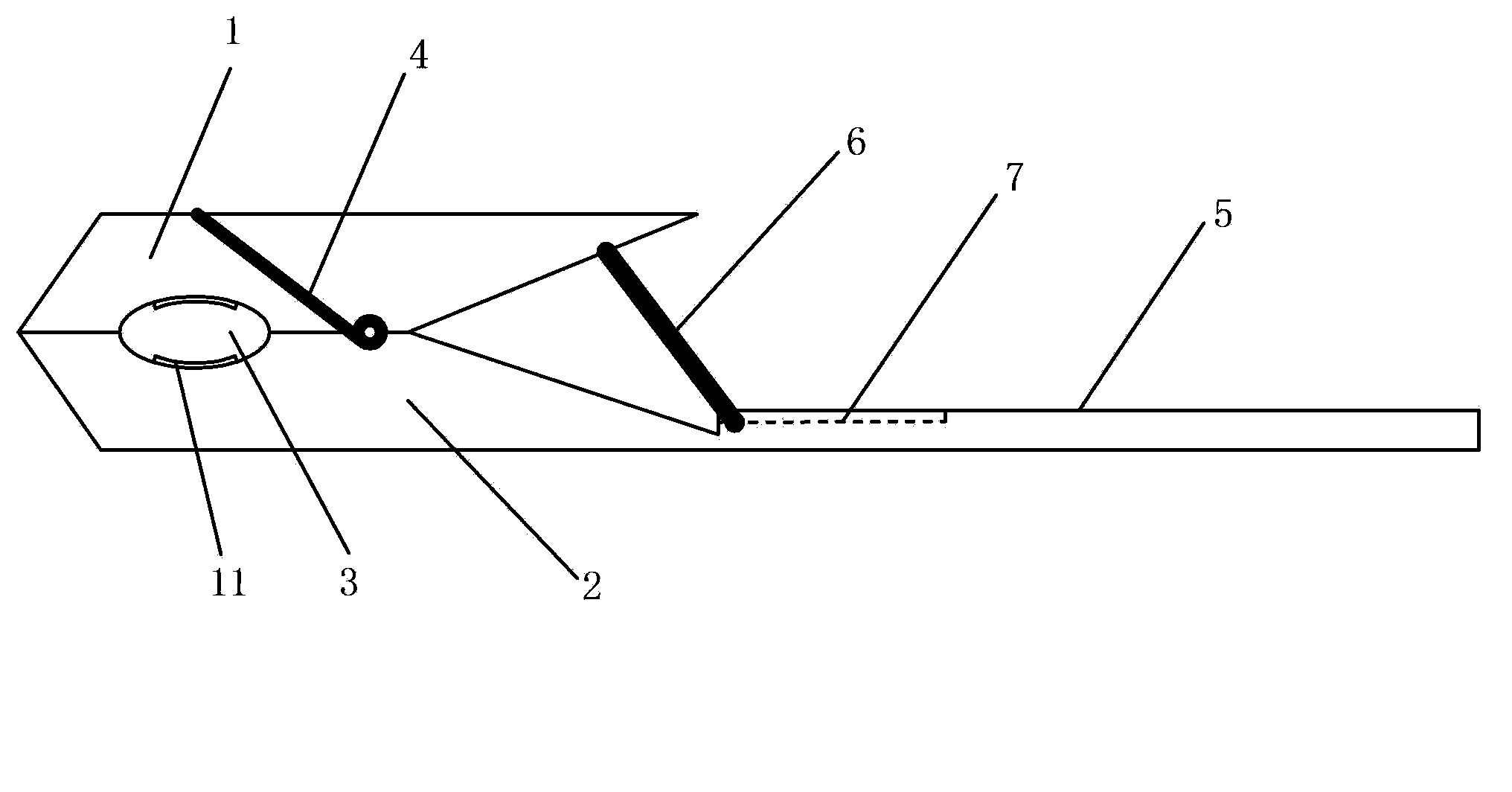

[0017] Depend on figure 1 , 2 As can be seen from the test tube clamp shown in 3, it includes a concave upper clamp block and a lower clamp block, a hand-held part connected with the lower clamp block, the upper and lower clamp blocks are connected by a metal wire with a spring, and the upper and lower clamp blocks The recessed part forms a space for clamping the test tube, and a supporting rod capable of supporting the upper clamping block is provided at the connection position between the handle part and the lower clamping block, and the supporting rod is provided with a fixing device. Wherein, the fixing device is a bolt that runs through the handle part and one end of the support rod, and nuts are arranged at both ends of the bolt. The handle is provided with a slot for storing the support rod. The concave parts of the upper clamping block and the lower clamping block are provided with anti-skid gaskets, which can better prevent the test tube from slipping.

[0018] Whe...

Embodiment 2

[0020] Depend on figure 1 , 2 As can be seen from the test tube clamp shown in 4, it includes a concave upper clamp block and a lower clamp block, a hand-held part connected with the lower clamp block, the upper and lower clamp blocks are connected by a metal wire with a spring, and the upper and lower clamp blocks The recessed part forms a space for clamping the test tube, and a supporting rod capable of supporting the upper clamping block is provided at the connection position between the handle part and the lower clamping block, and the supporting rod is provided with a fixing device. Wherein, the fixing device is a screw that runs through the handle part and one end of the support rod, and the screw is provided with a nut. The handle is provided with a slot for storing the support rod. The concave parts of the upper clamping block and the lower clamping block are provided with anti-skid gaskets, which can better prevent the test tube from slipping.

[0021] When in use,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com