Catalyst regenerating device

A regeneration device and catalyst technology, applied in the direction of catalyst regeneration/reactivation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of complex structure, increased tar amount, high energy consumption, etc., and achieve sufficient and uniform heating , Improve catalytic efficiency, work stably and reliably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

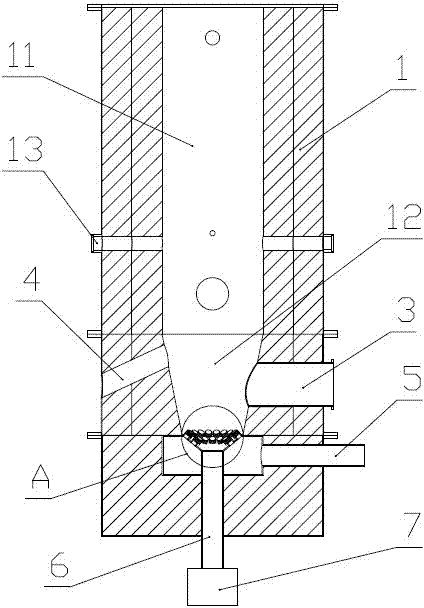

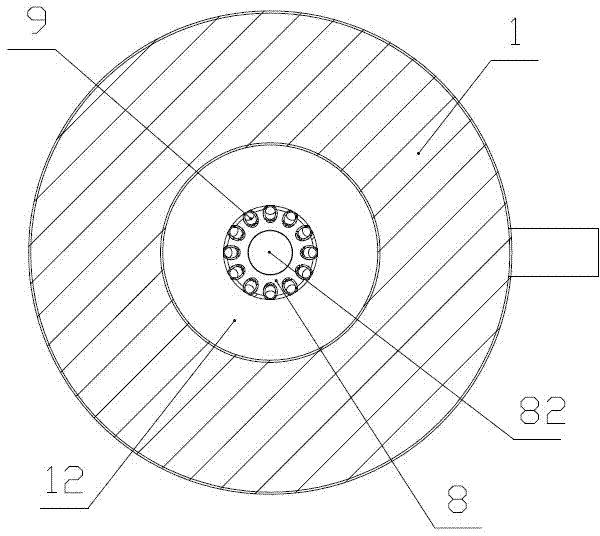

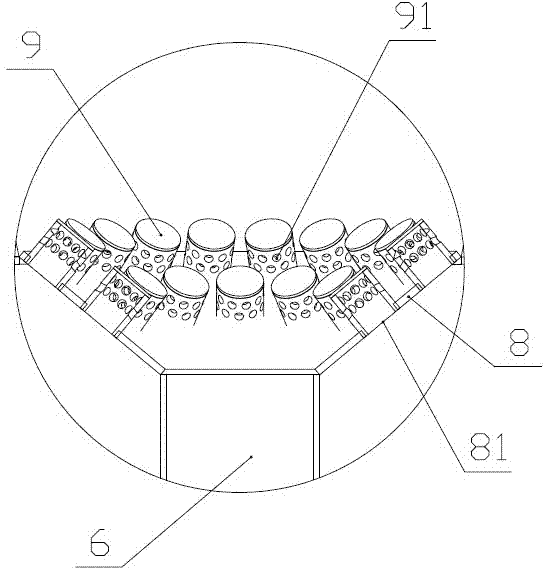

[0013] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0014] Such as figure 1 , figure 2 , image 3 As shown, the catalyst regeneration device of the present invention includes: a combustion furnace 1, an inlet 3 and an outlet 4 communicating with the inner chamber of the combustion furnace are respectively arranged on the side wall of the lower half of the combustion furnace 1. The bottom of the inner cavity of the combustion furnace is provided with an injection device that can quickly heat the catalyst to the required temperature and then output it from the outlet. The injection device is located below the inlet 3 and the outlet 4. The structure of the injection device is: The bottom is provided with a downwardly recessed concave baffle 8, and on the concave surface of the concave baffle 8, some injection pipes 9 are arranged, and on the side wall of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com