Automatic quantity-controllable vegetable washer

A vegetable washing machine and rack technology, applied in the field of automatic volume control vegetable washing machines, can solve the problems that the continuous operation cannot be completed one by one, the vegetable washing machine can only clean in batches, and the cleaning quality is unstable, so as to achieve the cleaning quality Stable, stable working performance, continuous cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

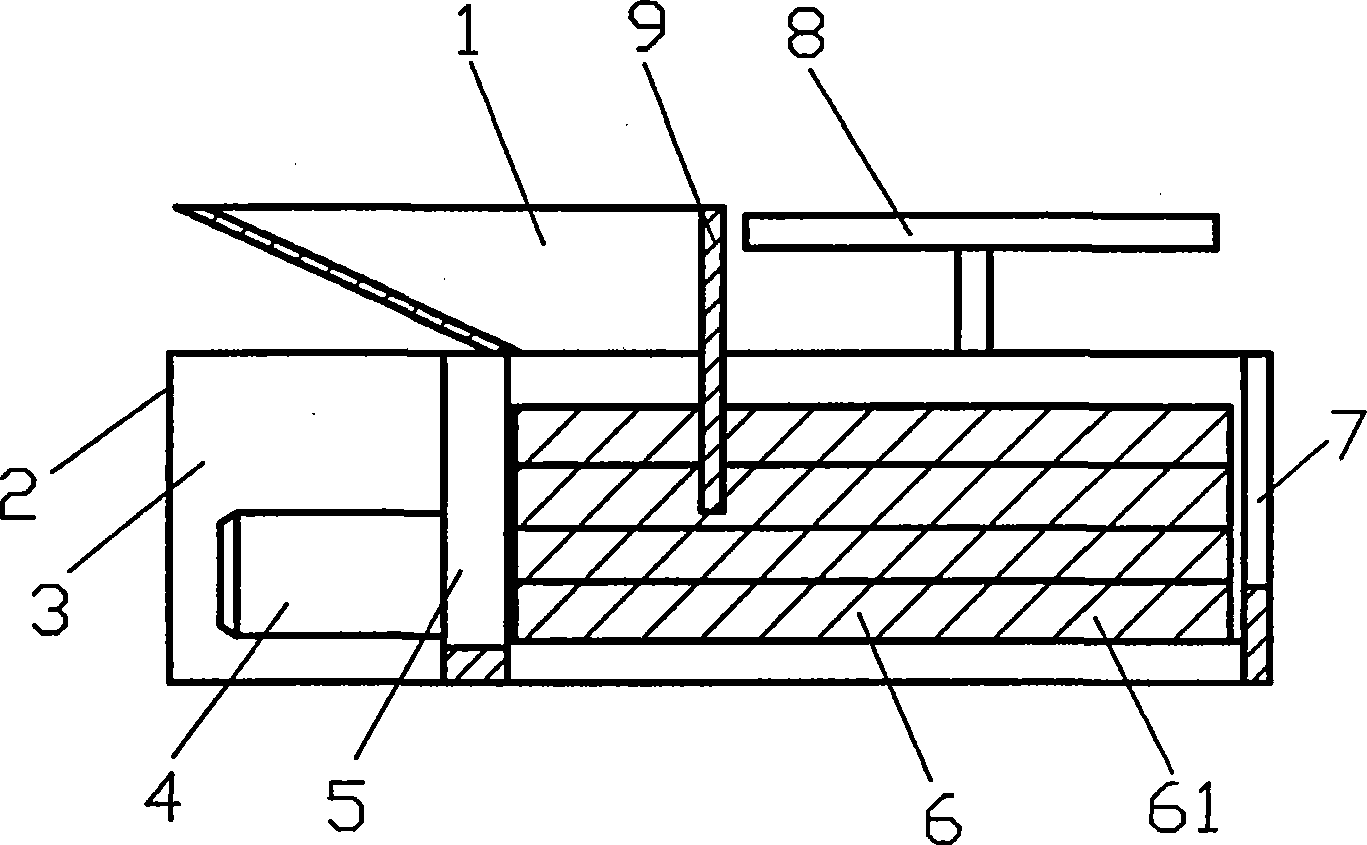

[0008] As shown in the figure, the automatic volume control vegetable washing machine is composed of a frame 2, a feed hopper 1, a motor 4, a gear container 5, a brush 6, a spray water pipe 8, and a blanking control baffle 9. It is characterized in that a motor 4 is installed at one end of the frame 2, the power output shaft of the motor 4 is docked with the gear assembly groove 5, and a motor shield 3 is installed on the outside of the motor 4; A number of brushes 6 are arranged in parallel between the feed port 7, the gear container 5 and the discharge port 7, and the brushes 6 are arranged in parallel in a U-shaped groove structure, and a spray nozzle is arranged above the U-shaped groove structure. The water shower pipe 8; the upper side of the U-shaped trough-shaped structure is also provided with a feed hopper 1 and a blanking control baffle 9 that can adjust the upper and lower positions; the raised bristles 61 of the spiral structure are uniformly distributed on the bru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com