A hickory cracker

A hickory nut shell breaking machine technology, applied in the fields of shelling, pod removal, food science, etc., can solve the problems of increasing the sorting process, reducing processing efficiency, increasing labor costs, etc., to achieve simple and convenient operation, stable striking force, The effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

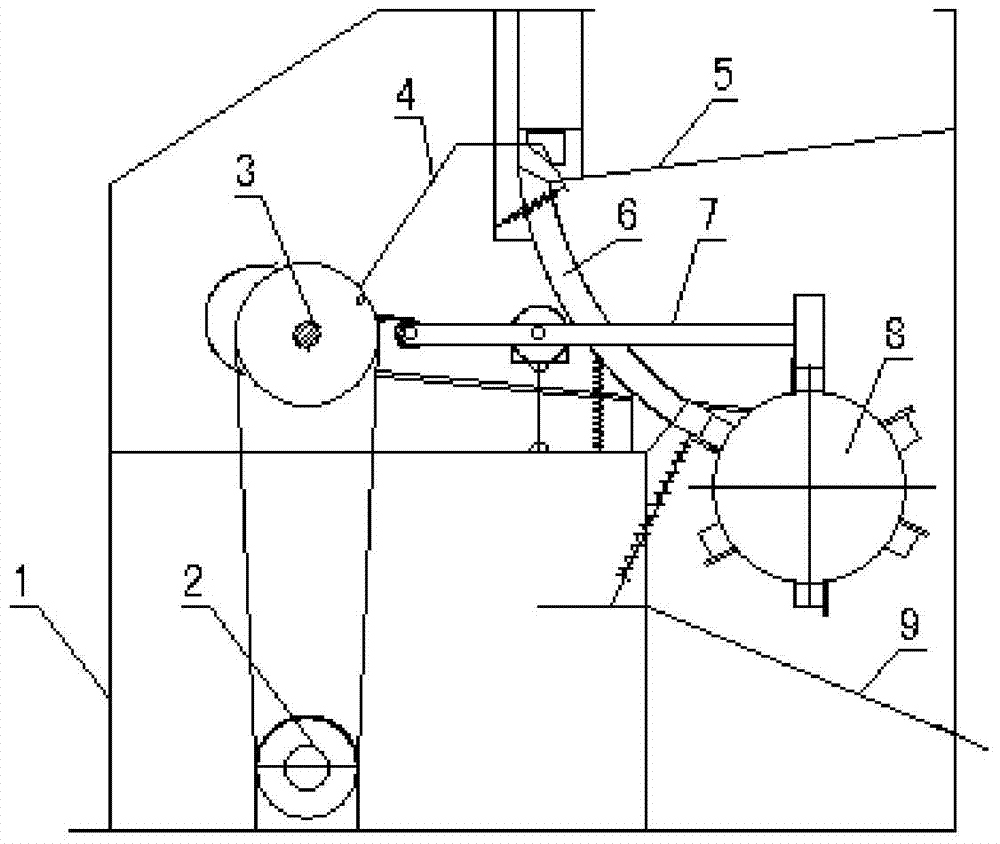

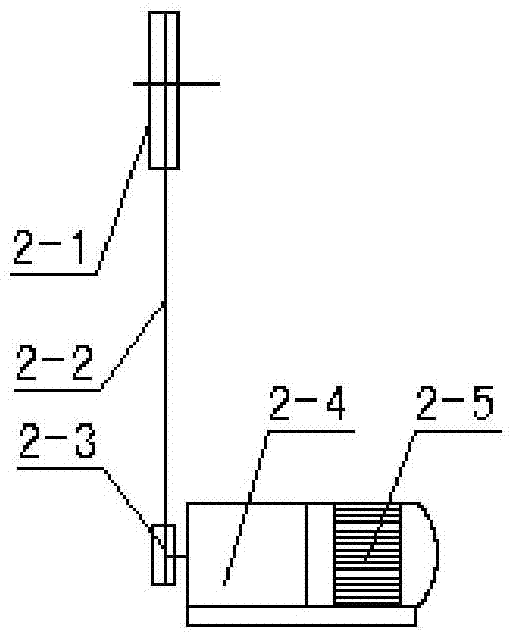

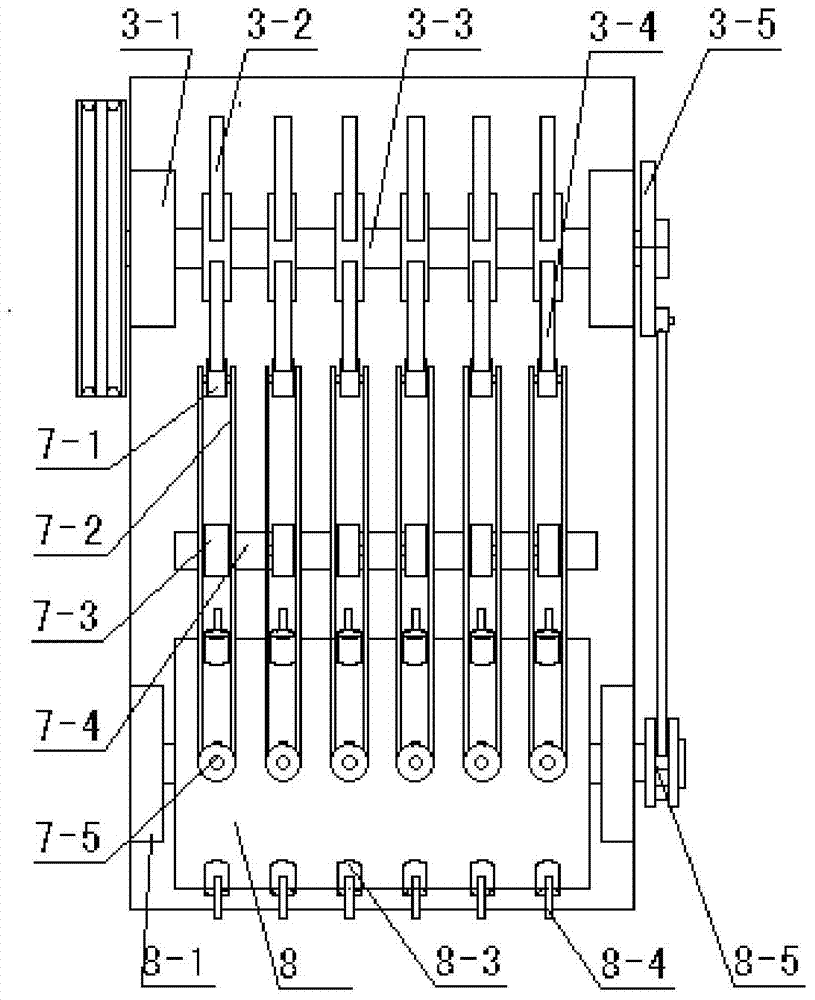

[0034] see Figure 1 to Figure 7 , a hickory nut shell breaking machine, comprising a frame 1, a feeding device, a shell breaking device, a discharge device and a power transmission device are arranged on the frame 1, and the feeding device includes a feeding hopper 5, a feeding pipe 6, The discharge end of the feeding hopper 5 is connected to the feeding port of the feeding pipe 6; the shell breaking device includes a material barrel 8 and a rod assembly 7, and a plurality of outwardly protruding hammers are uniformly arranged on the material barrel 8. Head seat 8-3, hammer head seat 8-3 outer end surface is inde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com