Engine start-up control device for hybrid vehicle

A hybrid vehicle and engine starting technology, applied in hybrid vehicles, starting devices with mechanical power storage, engine starting, etc., can solve problems such as engine speed reduction, connection shock, etc. Stall avoidance, improved drivability and ride comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

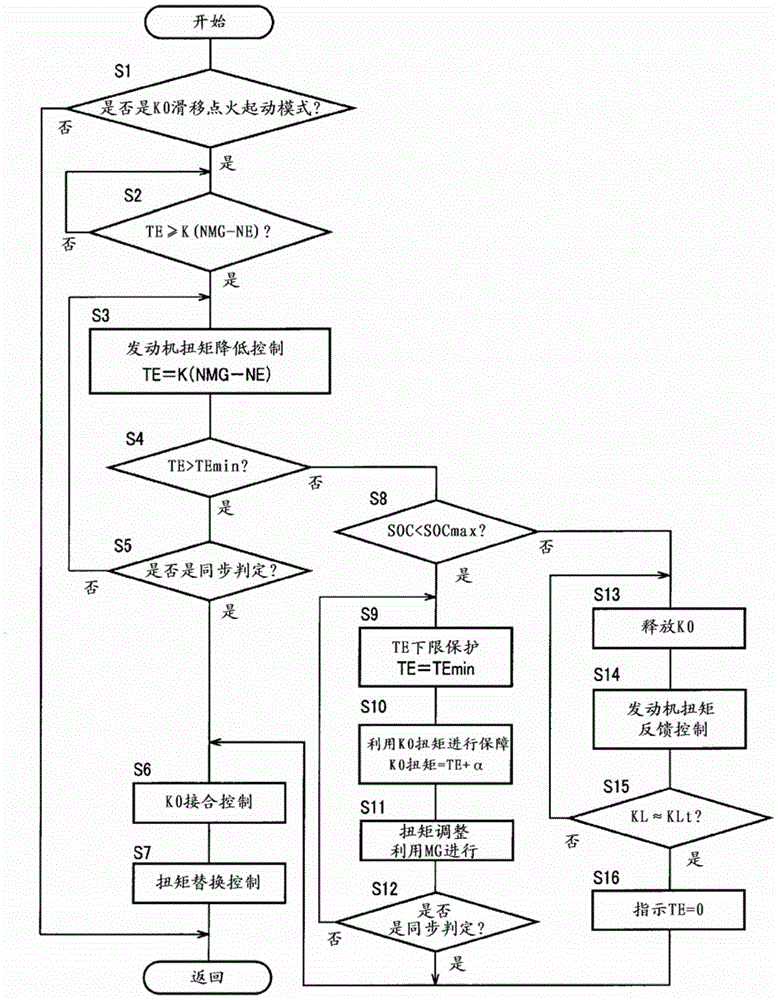

[0033] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

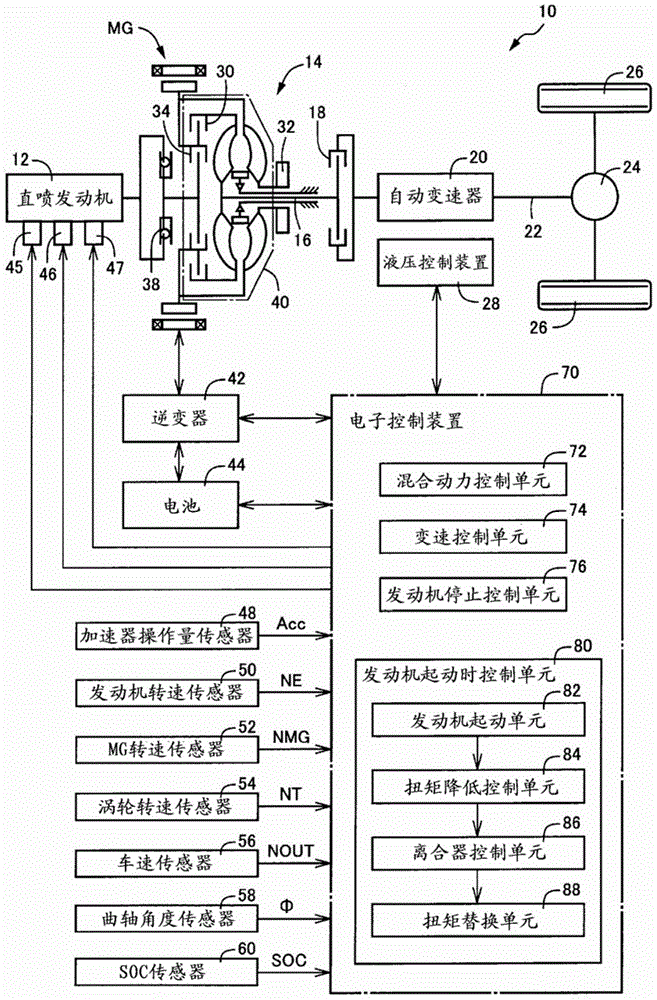

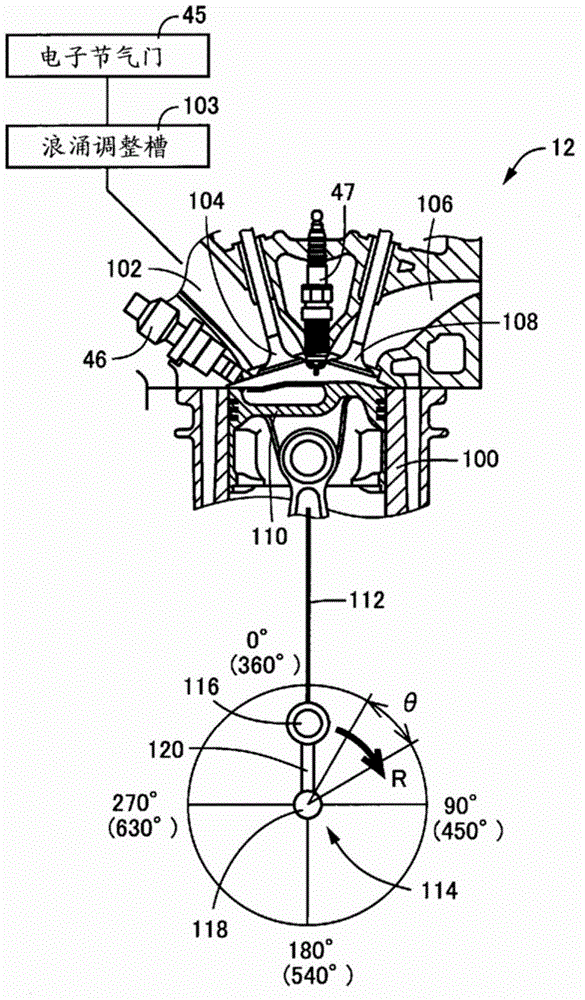

[0034] figure 1 It is a schematic configuration diagram including a skeleton diagram of a drive system of a hybrid vehicle 10 to which the present invention is applied. The hybrid vehicle 10 includes a direct injection engine 12 that directly injects fuel into cylinders, and a motor generator MG that functions as an electric motor and a generator as a driving force source for traveling. In addition, the output of the above-mentioned direct injection engine 12 and the motor generator MG is transmitted from the torque converter 14 as a fluid transmission device to the automatic transmission 20 through the turbine shaft 16 and the C1 clutch 18, and also through the output shaft 22, the differential The gear unit 24 transmits the transmission to the left and right drive wheels 26 . The torque converter 14 is provided with a lock-up clutch (L / U clutch) 30 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com