Method for preparing graphene fine wires

A fine circuit and graphene technology, which can be applied to the formation of conductive patterns and other directions, can solve problems such as the preparation method of graphene-free fine circuits, and achieve the effects of low cost and simple and controllable method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

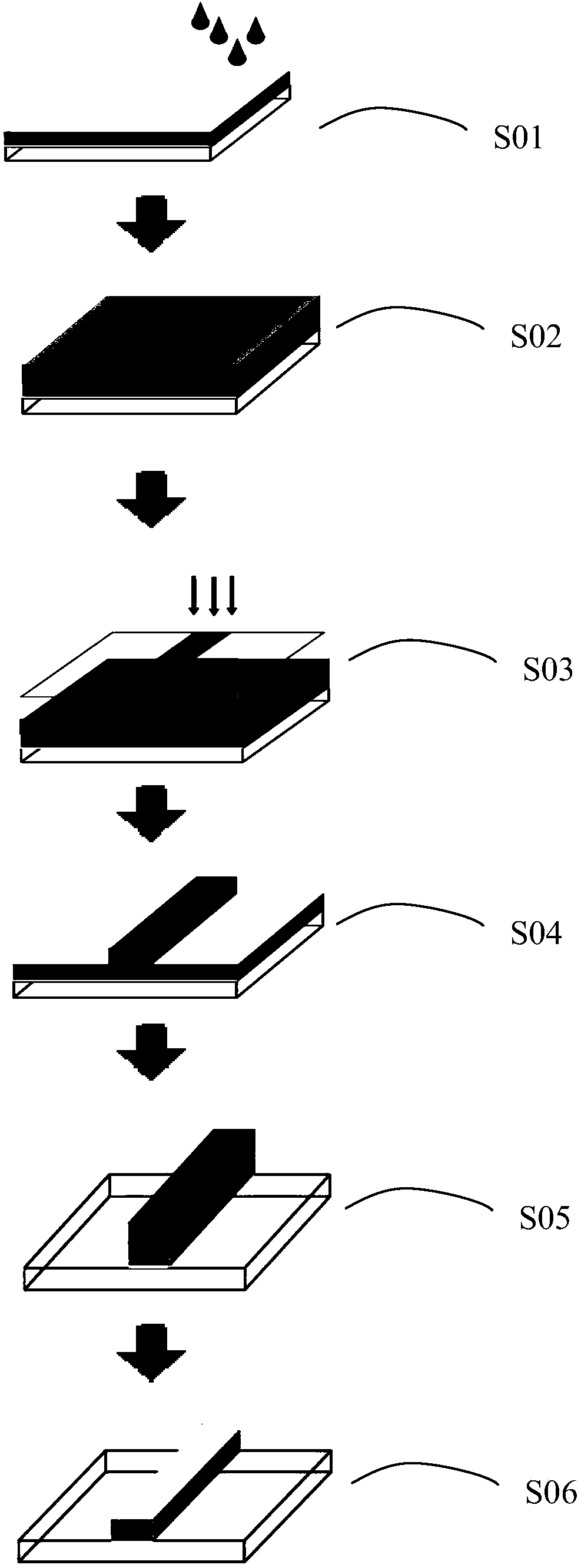

[0017] The embodiment of the present invention provides a method for preparing graphene fine circuit, comprising the following steps, specifically as attached figure 1 Shown:

[0018] S01. Cleaning: coating a layer of graphene film on the carrier substrate, and cleaning the surface of the graphene film;

[0019] S02. Coating: coating a layer of photoresist on the surface of the cleaned graphene film to form a photoresist layer;

[0020] S03. Exposure: Position and install a photomask parallel to the photoresist layer above the surface of the photoresist layer and designed with a sample pattern template, and perform exposure treatment on the photoresist layer with the above photomask installed, wherein, The size ratio of the sample drawing template to the physical circuit is 1:1;

[0021] S04. Developing: immerse the exposed sample in a developing solution for developing, and remove the exposed photoresist;

[0022] S05. Etching: placing the sample after the above-mentioned ...

Embodiment 1

[0048] A preparation method for producing fine lines of liquid crystal display screens from graphene, comprising the following steps:

[0049] S11. Cleaning: coating a layer of graphene film on the glass substrate, the thickness of the graphene film is 0.05nm, cleaning the surface of the graphene film, the cleaning is sequentially soaked in 0.5mol / L KOH solution 2.5 hours, rinsing with pure water, scrubbing, ultrasonic treatment with pure water, and drying, the drying temperature of the drying treatment is 110°C;

[0050] S12. Coating: coating a layer of positive photoresist on the surface of the cleaned graphene film to form a photoresist layer, the ratio of weight and number of photosensitive agent, resin, sensitizer and solvent in the photoresist is preferred It is 5:20:1:70, the volume ratio of photoresist and diluent in the coating process is 10:1, and the photoresist concentration after dilution is 5ppm;

[0051] S13. Exposure: Position and install a photomask on the su...

Embodiment 2

[0056] A preparation method for producing fine circuits of electronic chips from graphene, comprising the following steps:

[0057] S21. Cleaning: coating a layer of graphene film on the glass substrate, the thickness of the graphene film is 0.03nm, cleaning the surface of the graphene film, the cleaning is sequentially soaked in 0.6mol / L KOH solution 2 hours, rinsing with pure water, scrubbing, ultrasonic treatment with pure water, and drying, the drying temperature of the drying treatment is 120°C;

[0058]S22. Coating: coating a layer of positive photoresist on the surface of the cleaned graphene film to form a photoresist layer, the photoresist, resin, sensitizer and solvent in the photoresist The weight and number ratio is preferred 5:15:0.8:65, the volume ratio of the photoresist and diluent in the coating process is 9:1, and the diluted photoresist concentration is 8ppm;

[0059] S23. Exposure: Position and install a photomask that is completely parallel to the photore...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com